I’m reading about QuickCurve, an experimental nonplanar 3D print slicer.

Nonplanar FFF 3D printing has long been desired due to various effects of “normal” FFF 3D printing, which occurs layer by layer. The layers are visible, particularly on slight slopes, where the stair-step effect occurs.

We know that the FFF 3D printer’s motion system is fully capable of moving around in 3D space and could easily traverse curved paths. However, due to the complexity of computing the proper paths, almost all 3D print slicers simply go layer by layer.

Some experiments have been done to investigate nonplanar slicing for three axis FFF devices, with varying results. The major issue is that the structure of the nozzle and hot end can impact high-degree slopes. There is only so much angle they can physically handle.

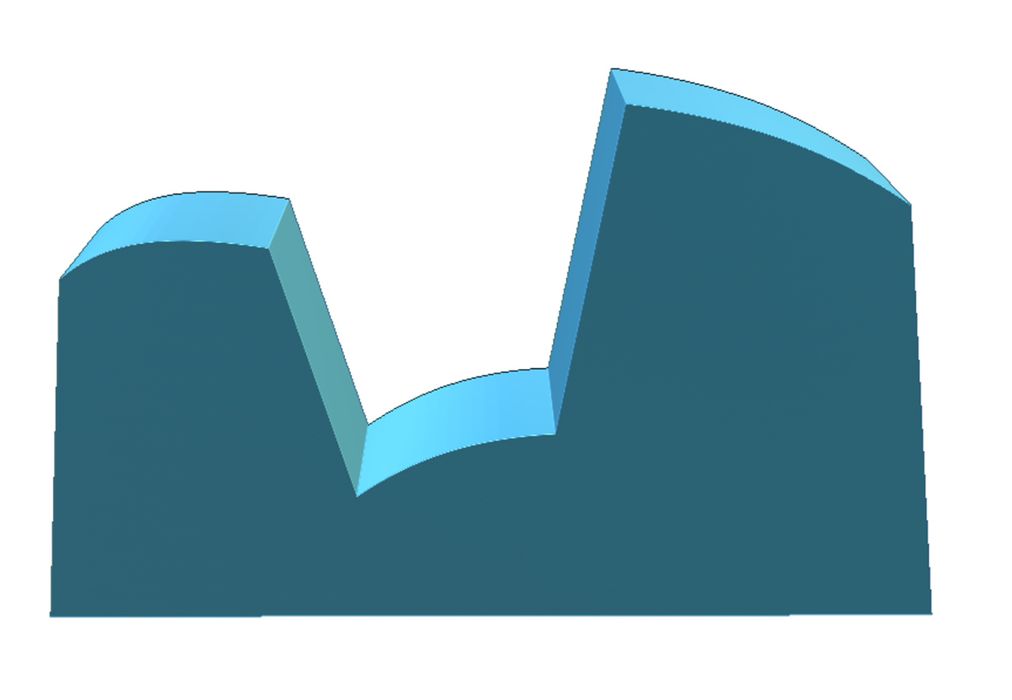

That’s why many nonplanar examples use low-sloping 3D models with “easy” curves. Consider a 3D model like this:

You can see that on the two end lobes the top could easily be handled, but that curved segment in the middle is challenging: how could the nozzle reach down to deposit it on a suitably curved toolpath? The answer: it cannot, the toolhead would strike the sides.

That’s why nonplanar 3D printing has been so much trouble: it can’t handle very many geometries.

Researchers seem to have found a way around this problem with a new experimental slicer called QuickCurve. Their approach is totally ingenious.

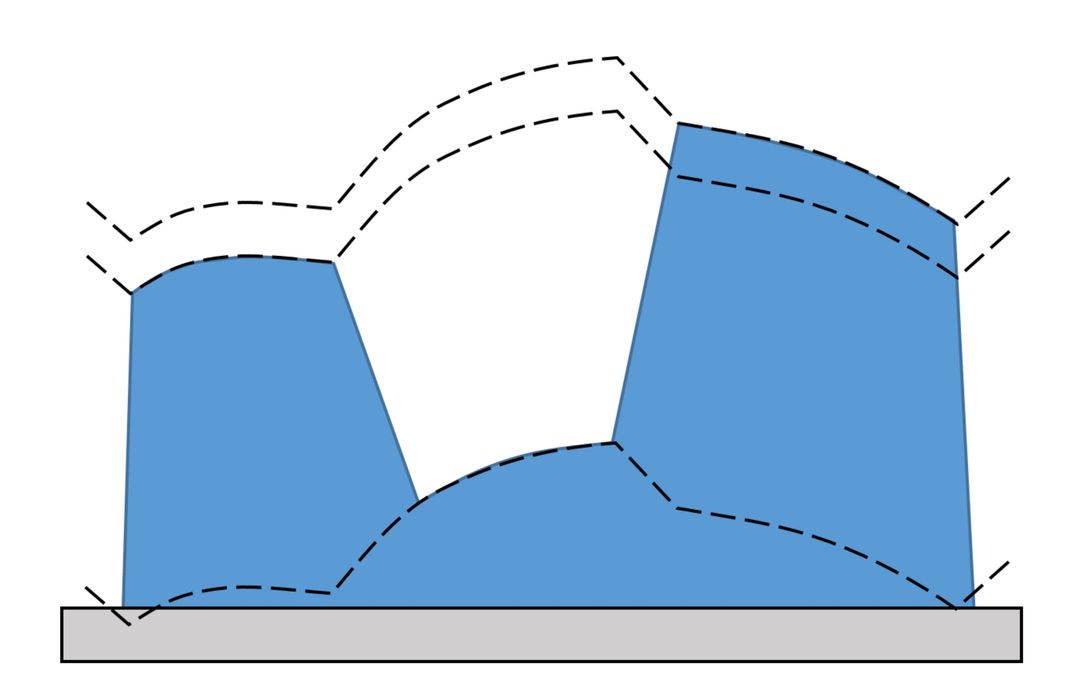

Instead of attempting to “curve” the entire part all at once, they decompose the object into segments that can be done one at a time and built on top of each other. Consider the pathological 3D model above, and now look how QuickCurve would handle it:

As the print proceeds it would print the curved middle segment, and then build up the side lobes later. Areas that are beyond the achievable angle would be printed in the normal manner.

This is a brilliant approach, as it maximizes the potential of nonplanar movements using the given hardware restrictions.

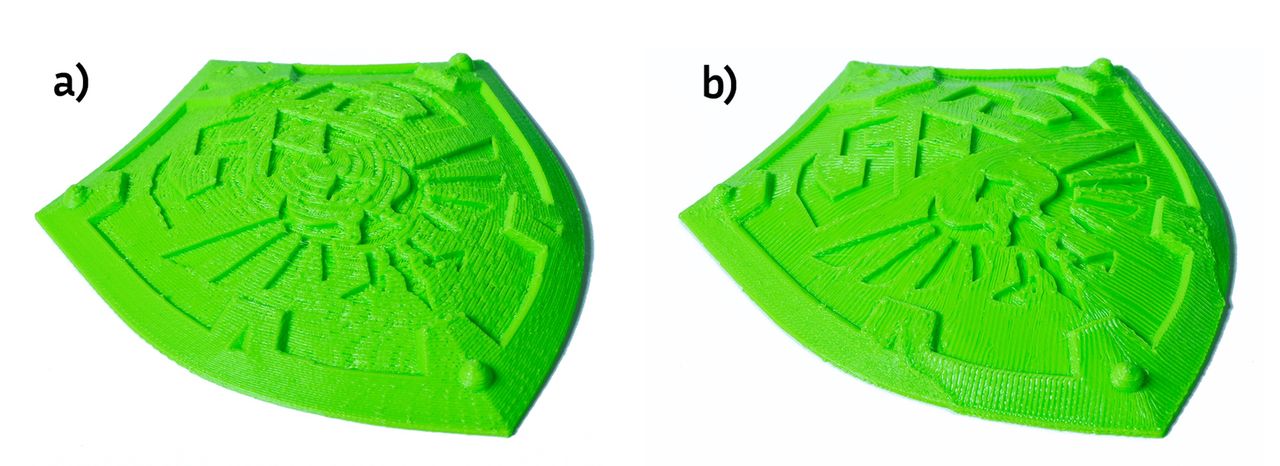

Here you can see a comparison of two prints, with the left using conventional slicing, and the right using QuickCurve. The surface looks terrific, and you don’t worry too much about what’s going on underneath. At top you can see an example aircraft printed in the same manner.

The researchers believe their approach could also be used to power multiple axis 3D print slicing.

For now this is an experiment, and one that appears quite promising. It may even be possible to integrate it into existing slicing programs, if the algorithms were made available. Perhaps we’ll see QuickCurve methods appear in UltiMaker Cura or PrusaSlicer in the future?

QuickCurve: Slightly Nonplanar.

Via ArXiv