Researchers unveiled “MobiPrint”, a home mobile 3D printer.

Wait, what’s a “mobile” 3D printer? In this case, it is a 3D printer that can literally move around a space and print an object wherever it is required.

Here’s how the MobiPrint concept works:

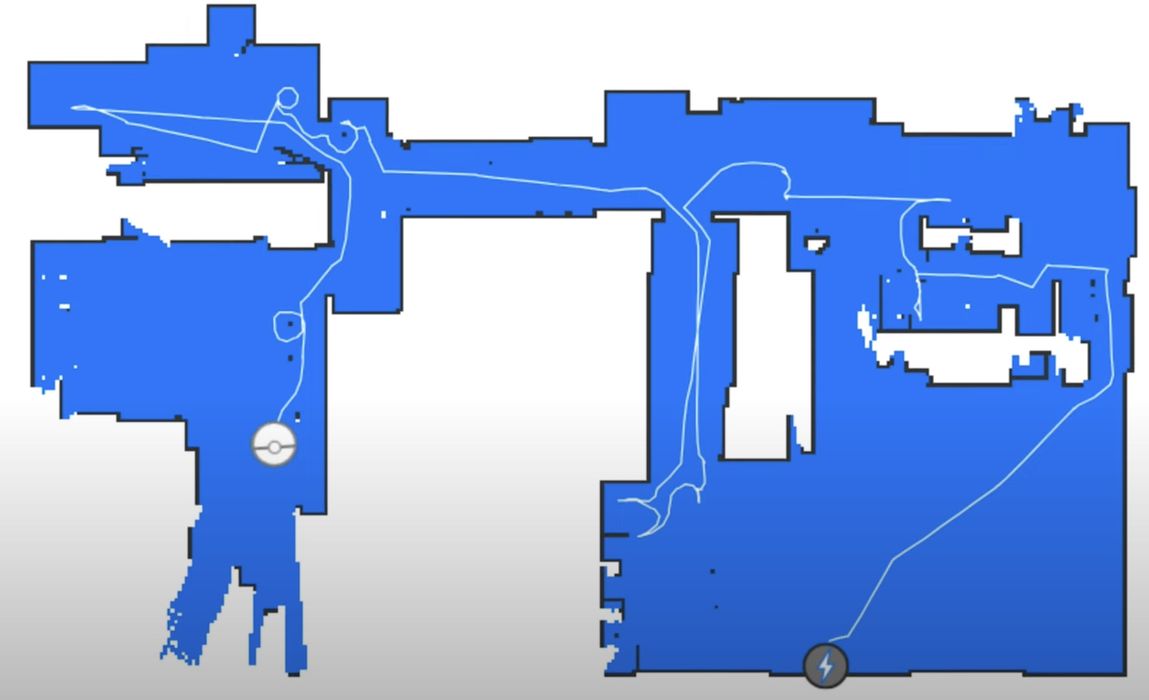

- The mobile printer travels around a flat space, say, a room, and generates a detailed LiDAR 3D scan of the area

- The area is then presented to the operator using software CAD tools that allow new 3D objects to be placed on the area scan

- The 3D printer then moves to the location of those new objects and 3D prints them in place

Need a vase in that corner of the room? Just place a suitable 3D model in the scan and MobiPrint will go and print it there for you. You don’t even have to put the vase there — it’s printed in the spot you specified.

While the 3D printing and scanning parts of the system is already well-understood technologies, this research tied it all together by adding the mobile components. The research had to investigate several key unknowns:

- Scanning and CAD model reconstruction speed

- Mobile printer location accuracy

- Ground surface adhesion during 3D printing

- Mobile payload capacity

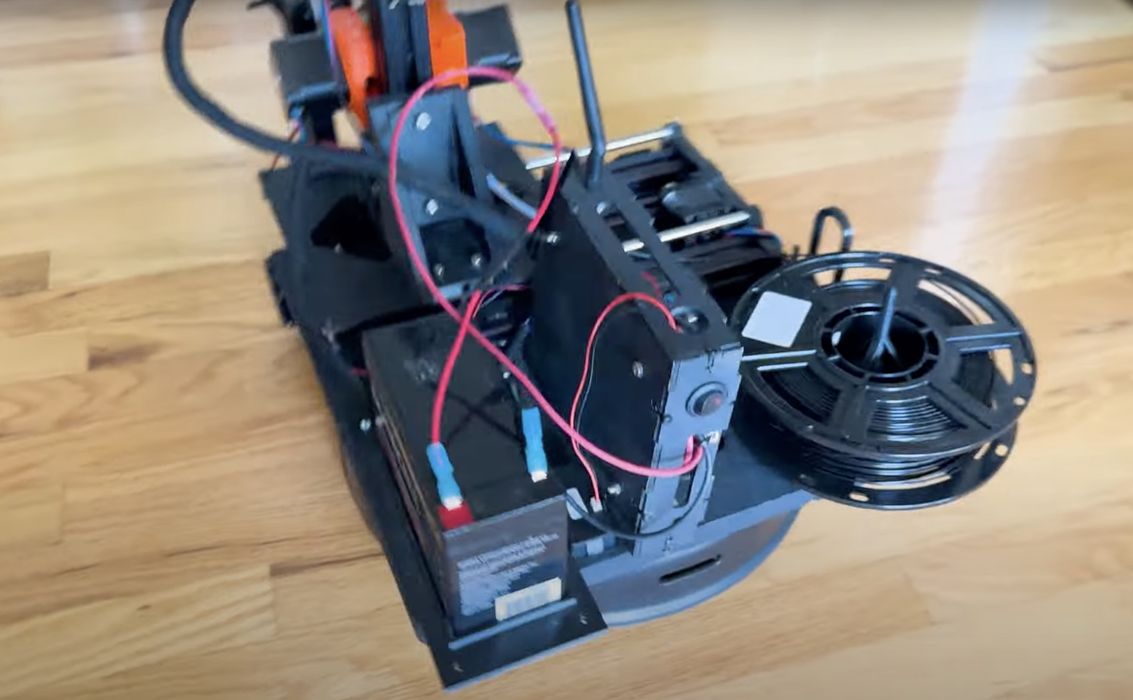

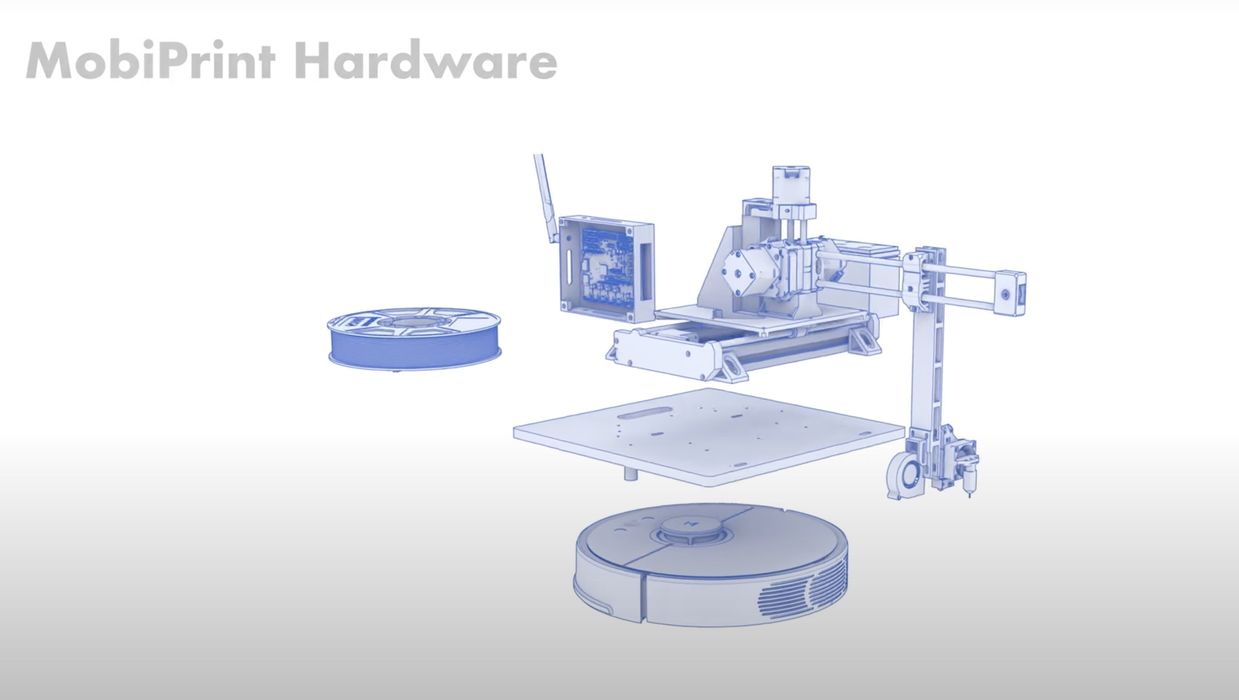

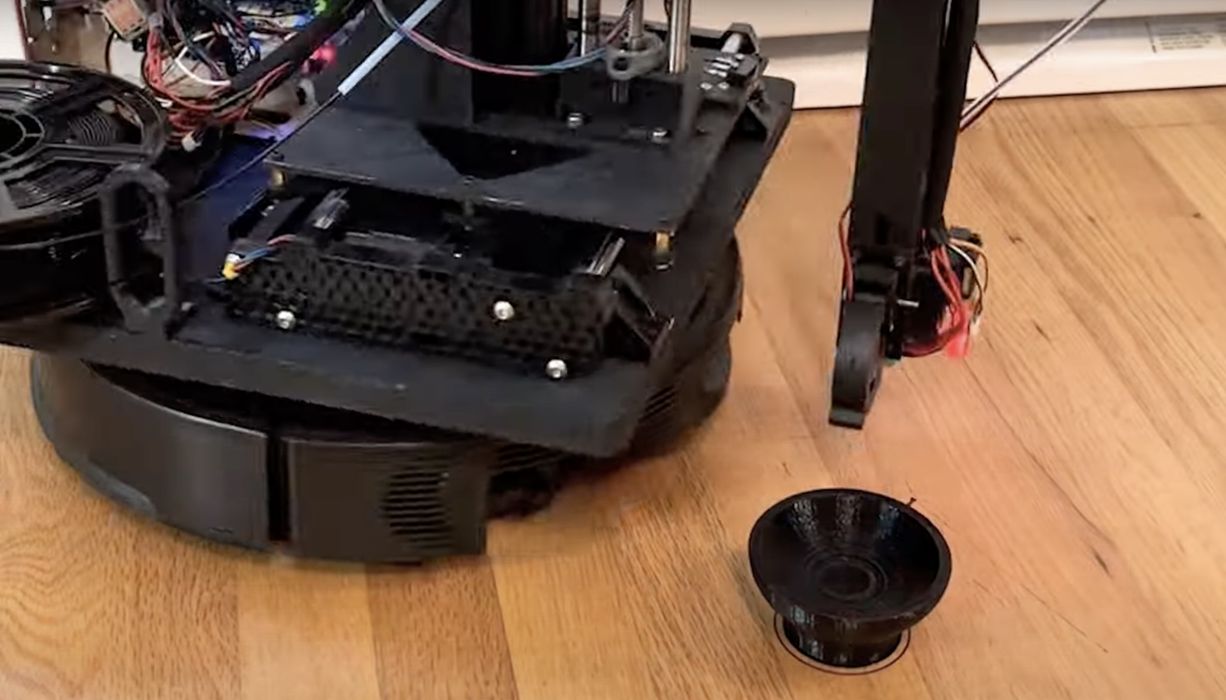

The researchers leveraged existing technology, and used a Roborock S5 vacuum robot as the mobile platform — after removing the vacuum system. On this hardware they adapted a Prusa Mini+ desktop FFF 3D printer.

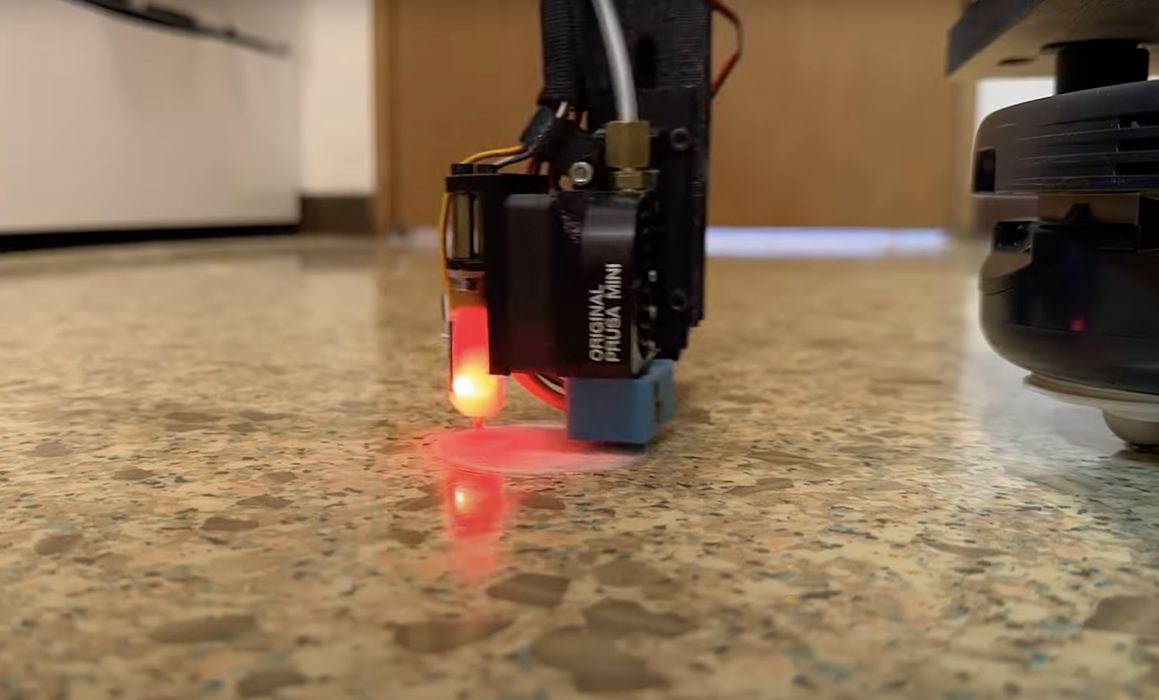

Of particular interest was their use of a BL-TOUCH sensor. Normally this is used in 3D printers to determine the heights of different points on the build platform. In this experiment the sensor was used to detect surface irregularities: a random floor is by no means flat.

The system built is able to print within a 180 x 180 x 65 mm build volume, which can be located on any flat surface that the robot can travel. That’s a bit less height than a stock Mini+, but this is an experiment, after all. MobiPrint is powered by an onboard battery, and is untethered. It has an operational time of approximately 3-4 hours.

While the 3D print job preparation was, as one would expect, with PrusaSlicer, the researchers had to build custom software to present the scan area for editing, with a “planning and editing” page. They also provided the software with a library of 3D models that could be placed in the area.

For location accuracy, they found the MobiPrint proof-of-concept could maneuver to locations in the print area to within about four percent accuracy. That’s not bad, but would preclude some applications that might require additional precision.

Adhesion was the most interesting aspect to me: it’s a critical aspect of FFF 3D printing, and operators go to great lengths to make their build plates perfect. How could this possibly work on random household surfaces?

The researchers tested four common floor surfaces for adhesion: hardwood, vinyl, ceramic and carpet.

Yes, carpet — it was a low-pile carpet, however.

They found that carpet provided the greatest adhesion, which isn’t surprising as the plastic would entangle with the carpet fibers. They measured the release force at a notable 50N. Vinyl was also decent, with a 37N release force required. Hardwood was much worse, at only 3.7N.

Ceramic surfaces didn’t work at all, as one would expect: they are quite cool and likely caused almost immediate warping.

The researchers found that while 3D printing was possible on some of the surfaces, the prints were subject to ringing artifacts, likely due to the shakiness of the hybrid MobiPrint platform.

Why would you want to use a MobiPrinter? The researchers identified at least four likely applications:

- Accessibility Aids: printing tactile structures for vision impaired, such as entryway signals or stairway warnings

- Home Furnishings: printing household functional objects, including pet feeders, footstools, umbrellas holders, vases, etc.

- Art: printing decorative objects, primarily floor art

- Pedestrian Flow: printing graphics on the surface to aid in walkway flows, including directional signs and other guidance

This is a fascinating concept that’s without precedent in the 3D print world. Remember that this is merely an experiment, and the concept may never become a commercial reality.

That said, one can easily imagine a variety of potential applications:

- Rent an advanced MobiPrint from Home Depot to spend the weekend printing items for your living room

- An industrial MobiPrint could be a tool for construction teams, which would be used to automatically print components at a build site

- Event organizers could rent a MobiPrint to print floor signage for larger events

Finally, there’s one other twist to this concept. As designed, the MobiPrint prints while stationary. If its technology were improved to allow for printing while in motion, then we suddenly have a 3D printer with an infinite XY build volume.