Since strategically moving production to China, and its HQ to Singapore, the company is taking advantage of the Asian landscape to further advance strong, lightweight manufacturing technology.

In an industry as dynamic and rapidly evolving as 3D printing, companies that continually adapt and innovate not only survive but thrive. Anisoprint, a name synonymous with the pioneering development of continuous fiber composite 3D printing technology, is one such company. With a significant strategic pivot, Anisoprint recently moved its HQ to Singapore and its production to Suzhou, China – marking a new chapter in its journey of redefining additive manufacturing.

Turning Eastwards

Anisoprint’s recent move of manufacturing to China was part of its well-considered strategy, accelerated by the challenging investment climate in Europe. The transition involved opening a new office in Shanghai in December 2022, amidst Europe’s dwindling investment prospects.

“Most of the changes happened with our move manufacturing to China,” said Fedor Antonov, Founder and CTO of Anisoprint, during our interview, in which he highlighted that the decision to relocate was driven by the need for a conducive environment for fundraising and expansion. “Investors in Asia have a better understanding of hardware and more success stories, making it a fertile ground for hardware startups. It was a very interesting insight. Investors here in Asia definitely have much more of an appetite towards hardware. And last year, unlike in the West, when everyone was discussing the downturn of 3D printing, with evaluations and revenues declining – in Asia, it was completely the opposite, there’s hype, it’s growing. 3D printing was very hot last year, and we kind of caught this wave.”

The dynamic Asian venture capital landscape offered Anisoprint and its composite 3D printing business a stark contrast to its experiences in Europe. Upon announcing their Chinese office, they were swiftly approached by Asian VCs – experiencing a fundraising process that was not only faster but also more attuned to the hardware sector. “If you chase investors, you can never raise. You have to be in the position where the investors chase you – this is when you raise. That’s what happened to us in Asia,” said Fedor. “We first touched down in mid-April, and we closed the round in the beginning of July.”

The company, until February 2022, had most of its R&D team in Russia. However, geopolitical events prompted a swift move to Luxembourg – followed by the transition to Asia. This move was aimed at harnessing China’s advanced supply chain, human resources, and manufacturing capabilities. After setting up, the team hired and trained 40+ new employees, simultaneously.

“In comparison, Luxembourg has no talent pool, and the prices are very high. Even the state support is much better in Asia,” said Fedor. “When you’ve never been to Asia and you’ve heard all the stories, which basically have nothing to do with reality, then yeah, it’s scary. But as soon as we came here, we saw how it really works.”

More recently, Anisoprint moved its HQ to Singapore, enticed by the country’s integrated financial services, and access to multiple different funds and investment companies. Singapore is also a democracy with an appealing legal system, a stable society, and an influx of Asian immigrants looking to invest in new opportunities. Essentially, the company will be based in Singapore, but with all the benefits of Chinese manufacturing.

New ‘Nova’ system

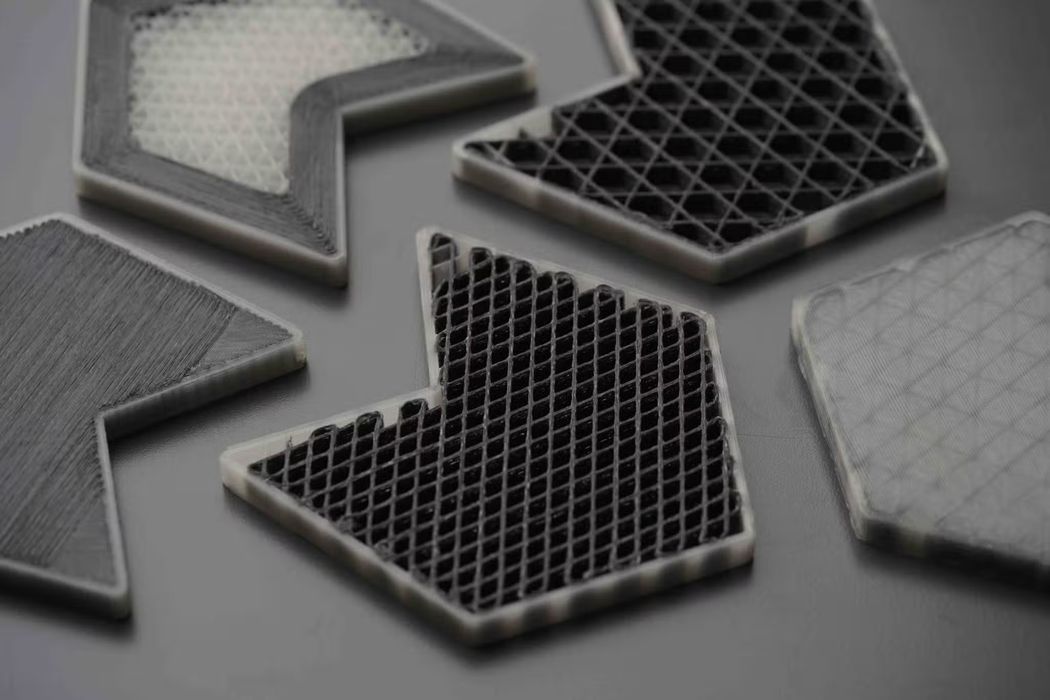

In the product realm, the company is preparing for the upcoming release of Nova, a semi-industrial printer that represents the second generation of their technology. The Nova printer boasts a unique set of features, including a tool-changing system for up to four printheads, automated leveling and calibration, and a built-in material storage chamber. It’s designed to be versatile – accommodating various materials and allowing for intricate, high-strength composite structures.

The desktop system is fairly simple, especially compared to Anisoprint’s fully industrial machines, but it has all the auto motion and sensors, which the previous generation didn’t have. Importantly, it also has the tool-changing system for up to four printheads – a concept that is quite powerful for continuous fiber printing. “Within one machine, you can combine fibers of different thicknesses, or you can combine fibers and embedded wires. This adds much more functionality – so you can not only print with continuous fibers which basically give strength, but you can also use co-extrusion to print sorts of embedded electronics,” said Fedor.

Size is an important factor to consider when evaluating the impact of 3D printed parts. This is why Anisoprint chose to keep the build volume of the Nova system as large as practical – a similar size to the company’s Composer A3 system (460 × 297 × 210mm). The bigger the part, the higher absolute lightweight savings you can achieve. “There is a pretty good market for large jigs and fixtures, which we will definitely address, but the goal for now is to find more applications in end-use parts,” said Ryan Liu, the new CEO of Anisoprint.

Read the rest of this story at VoxelMatters