There’s a new belt 3D printer on the market: the IdeaFormer IR3 V2.

IdeaFormer, a brand of Zhuhai Bell Technology Co., Ltd., has been producing a variety of desktop 3D printers since 2016. Previously, they marketed the IdeaFormer IR3 V1, but now there’s a new V2 release.

The IdeaFormer IR3 V2 is a belt 3D printer, which are quite unlike the standard Cartesian or delta desktop 3D printers that cover the market. Instead of printing on a typical print plate, belt printers have a moving “conveyor belt” where material is deposited.

Belt printers usually print at an angle, such as 45 degrees. This means the layers of the print are not stacked vertically, but at an angle. A good way to visualize it is to take a loaf of sliced bread and tip all the slices at 45 degrees. Each slice is created by moving the belt forward the width of the layer.

Why print in this complicated manner? There are two main advantages.

The first is that parts can naturally roll off the end of the belt for collection. This effectively clears off the build area and thus you can continuously produce objects without intervention — so long as you have enough filament on the spool.

The second advantage is that you can print objects larger than the print area. In theory, a print could extend far off the end of the belt, making it possible to, say, print a life-sized large sword. However, in practice, you have to provide some kind of support system for the dangling end of the print.

The IdeaFormer IR3 V2 is a belt printer, but it has a difference we haven’t seen in any other belt printer: it operates at high speed through the use of Klipper firmware. This is a technique used now by many desktop 3D printers, and now it’s available in belt format.

One of the classic problems with belt printers, which have largely kept them from becoming popular, is the belt itself. Most belt printers have some type of fabric or polymer belt. These tend to warp over time, particularly when repeatedly exposed to heat. It’s also hard to ensure parts stick properly to these surfaces, making printing challenging.

The IdeaFormer IR3 V2 solves this by using a metal belt that should not distort and be more able to handle heat exposure. But how do 3D prints stick on the belt? Their solution was to coat the metal belt with PEI, the same material used on standard spring steel print plates on other 3D printers.

This means the adhesion capabilities of the IdeaFormer IR3 V2 should be comparable to typical 3D printers.

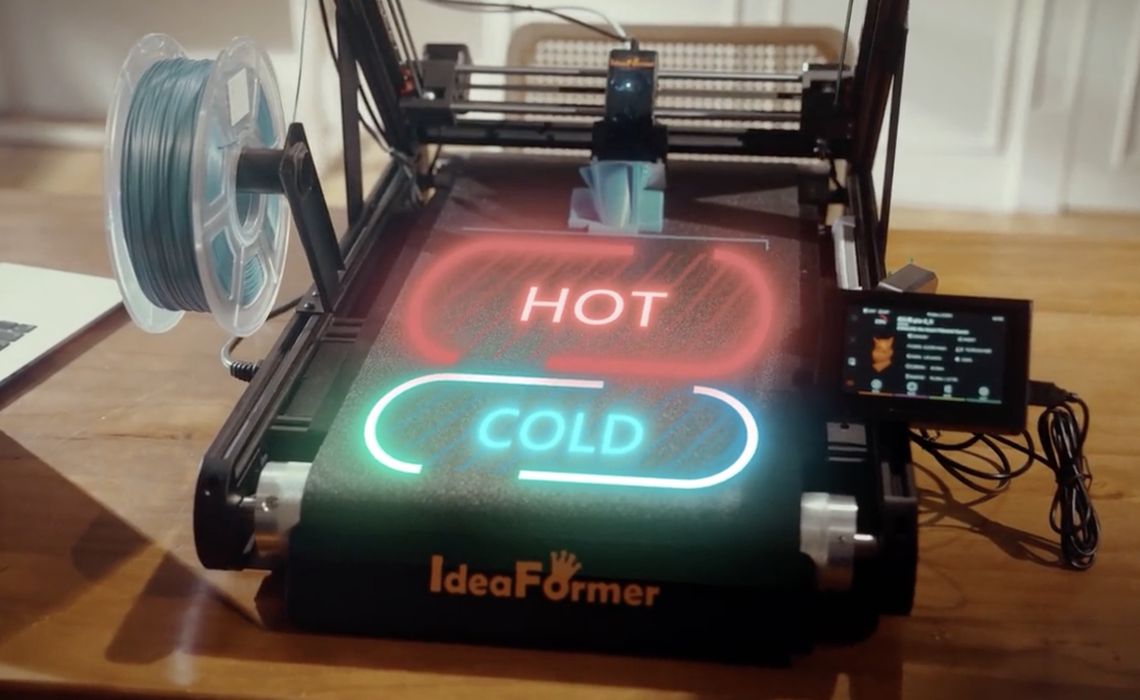

Another interesting feature of the machine is that there is a heated and cool area of the belt. Some belt machines I’ve tested failed miserably because they maintained heat all the way to the end of the belt. This meant that prints would be soft when rolling off the belt, almost always bending the parts. Here the IdeaFormer IR3 V2 has a cool section to ensure parts are sufficiently hard to withstand peeling off the belt.

For longer prints, Zhuhai Bell Technology also offers an optional extension roller accessory to handle longer prints as they roll off the belt.

Zhuhai Bell Technology said the machine can print at a maximum speed of 400mm/s, which is typical for high-speed desktop 3D printers these days. They state a maximum volumetric flow rate of 26 cubic mm/s, which is sufficient for this speed. The printhead can also accelerate at up to 20,000mm/s/s.

There is an optional enclosure for the system, which could assist when 3D printing certain warp-prone materials like ABS, ASA, and even nylon.

The machine has a standard 4.3” color touchscreen with an easy-to-use interface. It’s also possible to monitor and control the machine remotely through the network and via an onboard webcam that shows what’s currently happening on the device.

You’re probably wondering about the build volume of the IdeaFormer IR3 V2. It’s 250mm x 250mm x well, however long you want to print. Belt 3D printers have an infinite Z-axis.

For material compatibility, the IdeaFormer IR3 V2 is able to handle all the basic 3D print materials, including “PLA, HIPS, PETG, ABS, TPU, Nylon, etc.” However, I suspect that the warp-prone materials may require special attention and the optional enclosure.

For software, the company provides IdeaMaker. While both the machine and software begin with the word “Idea”, they are from different sources. IdeaMaker is Raise3D’s open platform, and it just happens to support belt 3D printers. It’s one of the few slicing tools that does, so it’s not surprising that Zhuhai Bell Technology adopted it.

The IdeaFormer IR3 V2 has been launched on Kickstarter, and there are only a few days left to place an order, if you’re interested. They’ve priced the belt printer at only US$558, which is quite inexpensive for a belt 3D printer. Of course, the price will likely rise after the launch, but it’s still a good deal.

Via Kickstarter and IdeaFormer