Most people want to recycle their 3D print waste, but have no options to do so.

3D printing is becoming a wasteful approach to making parts. This is ironic, as the technology was initially billed as being less wasteful, compared to CNC machining. However, in recent times more waste is produced due to more complex parts requiring large support structures, iterative development producing multiple versions, and “poop”.

The latter is the product of recent multimaterial 3D printers that switch filaments on the fly. In order to clear the previous material out of the hot end, they do a purge of fresh material, which produces a little “poop”. As jobs proceed, these 3D printers continually poop, sometimes creating massive piles of waste plastic.

Most of the time these waste materials head to the local landfill. While the most common 3D printable materials, PLA, ABS and PETG are quite recyclable, it requires an operation specifically designed to do so. These don’t exist in most regions.

We’ve seen a couple of firms specializing in accepting recycled 3D print waste, but most (all?) of them have disappeared. It seems to be a challenging business.

One that I’ve recently discovered is St. Louis-based Printerior.

The company sells spools of recycled PLA material. That in itself isn’t so unusual: there are several companies that market recycled PETG and sometimes PLA. However, most of those operations get their input polymers from specific industrial sources. For example, a company might make a contract to receive used Pepsi bottles — only — to make recycled PETG.

Printerior is different in that the source of PLA is …. well, you!

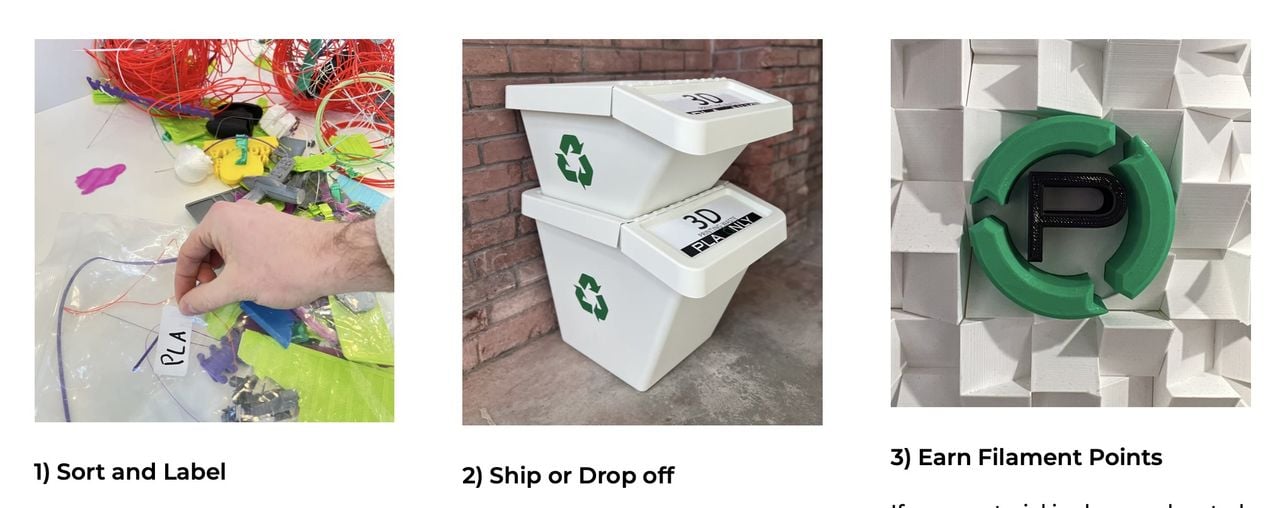

You can open a “recycling account” with the company, which allows you to send them your 3D print waste. Here’s how the process works:

Three steps: sort & label; ship or drop-off; earn points. The idea here is that as you provide recyclable material, you accumulate points that can be used to discount spool purchases. This gamifies the recycling activity, hopefully encouraging participation.

The second step is where issues appear. Printerior’s program allows participants to drop off their waste at their St. Louis plant at no charge.

That’s terrific — if you live in St. Louis. If you don’t, you have to pay for shipping your waste to the company from your location.

There’s a number of issues when shipping:

- The act of shipping generates pollution

- It costs the participant money to ship

- It’s more work and cost, discouraging participation

This is why filament production is inherently a local activity. It’s becoming a commodity that differs in price mainly by the shipping cost.

Does this mean that every urban area should have a “Printerior equivalent”? That would enable easy drop off of waste, but having hundreds of local manufacturers of filament is likely unsupportable. These numerous producers would not have enough market to sustain themselves.

What if Printerior or other recyclers paid for the shipping costs? That has been tried in the past, and it didn’t financially work.

Recycling of 3D print materials might seem like a good idea, and it can be. However, in practice it is very challenging for a business to operate. We aren’t likely to see widespread 3D print waste recycling anytime soon.

In the meantime, you can use Printerior, especially if you are in St. Louis.

Via Printerior