Our review of BigTreeTech’s Panda Series of Bambu Lab upgrades concludes.

This is part two of a two-part series; please read part one.

Panda Touch

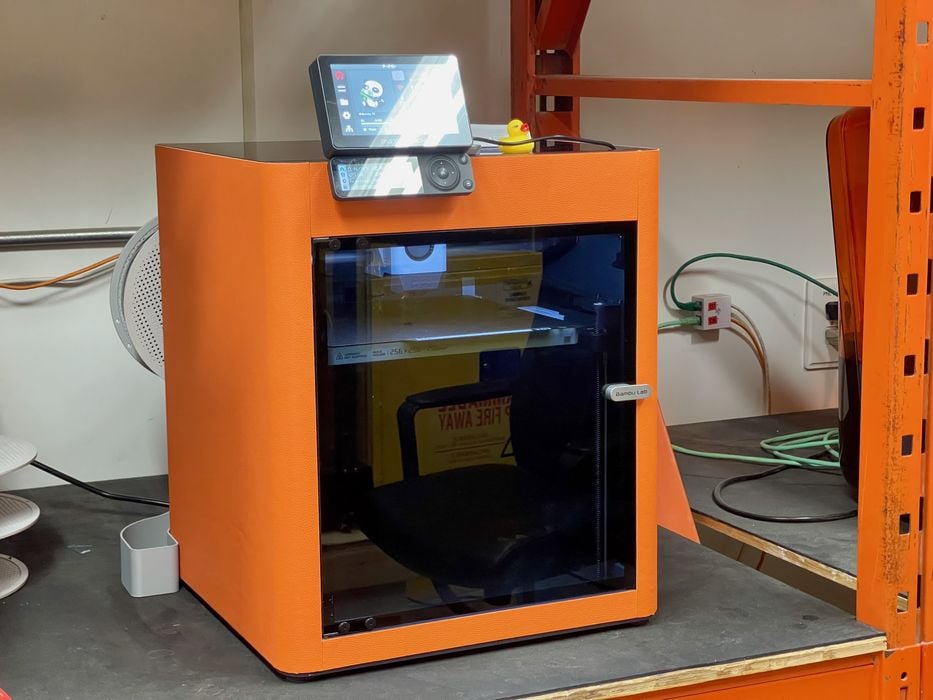

The Panda Touch is the most complex of the upgrades. It provides an advanced color touch interface for the P1S.

The most notable difference between the P1S and the X1C is that the P1S has a pretty low-end digital display instead of a touch screen. This style of interface has basically disappeared in the market, leaving the P1S with a noticeable degradation. The Panda Touch rectifies this by installing a control panel that’s even better than the X1C’s touchscreen.

The Panda Touch actually has a prerequisite: the Panda Hub. This is a set of two USB-A ports that are added to the machine at the front. Download and 3D print the hub’s enclosure, add press in place threaded inserts and assemble.

It’s easily assembled with a couple of bolts and then installed on the P1S. One of the ports is used by the Panda Touch to access the P1S.

The Panda Touch is non-destructive; you don’t remove the original digital display panel, as the Panda Touch fits on top of it. This is done with a mount, shown here.

The mount requires a bit of easy assembly before placing it on the machine. It attaches with a strong adhesive under the peel-off cover.

The Panda Touch mount is placed just behind the original digital panel, which you can see underneath here.

Remember the Panda Hub? That’s where this USB cable comes from. It connects to the Panda Touch mount to provide signal and power for the panel. It is important to fit the cable into the clips on the printers frame, so it does not interfere with printer’s XY movement.

On the front side of the mount, you can see magnets that hold the Panda Touch, as well as the plugs for signal data. We found the Panda Touch to very easily click onto the mount.

Here’s the other side, showing the Panda Touch’s rear. The USB cable must be plugged in at the bottom, and the magnets do the rest of the work. Note that there is a power switch on the panel itself. It won’t work unless you turn it on!

Powering up everything, we then saw the Panda Touch asking for the operating language. There were no problems getting the panel going.

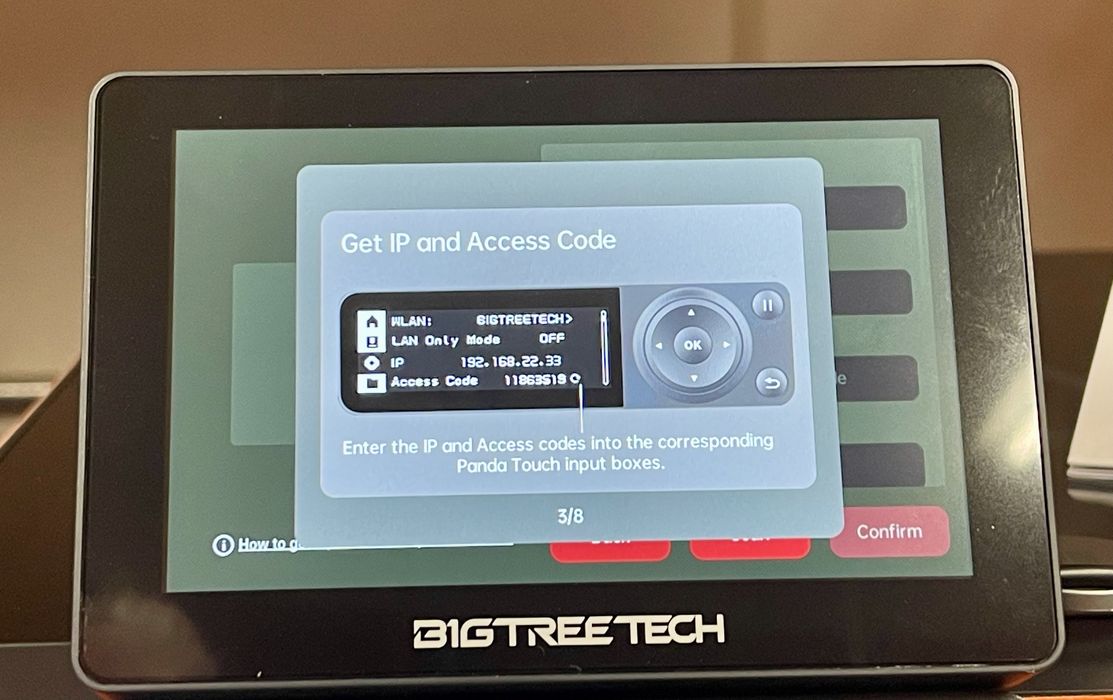

However, you do have to have certain information at the ready to enter into the panel. The Panda Touch is essentially a remote operations “app” for the machine, except that it happens to be bolted onto the machine.

For this, you will require an access code from the P1S. We had no trouble following the instructions to do so.

Once installed, the Panda Touch completely replaces the functionality of the original digital panel, and it really isn’t used anymore. The Panda Touch provides complete functionality for the P1S, including the ability to move axes, control the hot end, view the camera, and much more. It provides more function than the X1C’s panel and is larger.

One strange item we encountered was that the Panda Touch must be logged into the cloud to control changing temperatures on the hot end and build plate. You can move axes, but you can’t change the temperatures without authorization. This is likely a safety feature.

The Panda Touch is a computer on its own, and has firmware. The firmware can be updated with any web based device by downloading the firmware and then http’ing to the web address of the Panda touch and following instructions to upload the new firmware.

The Panda Touch is able to control not only the machine it’s attached to, but others as well. You just need to configure them. While we had another suitable machine present, we decided not to set it up on the Panda because we felt it would be too confusing for the casual operators in our facility: “Why am I using this machine’s control panel to run that other machine?”

Panda Build Plates

BigTreeTech sent us a small collection of different build plates for the 3D printer. Because Bambu Lab uses the same build plate geometry for the X1C, P1S, P1P, and A1, the Panda plates can be used interchangeably on all of these machines. All plates are coated on both sides (reversible), magnetically attached, and made from spring steel.

There are two packages here, the Panda BuildPlate Engineer Series, and the Panda CryoGrip BuildPlate.

The grey-colored Panda CryoGrip is designed for use with PETG and PLA materials only. It’s chemically designed to adhere to these materials without the need for heating the plate. Normally, these materials would require 50-70C temperatures to adhere to standard PEI plates, but here you can save the energy by not heating at all.

BigTreeTech states that these build plates reduce clogs, which is a strange thing to say: how does a build plate affect the extruder and hot end? The idea here is that because the plate isn’t heated, the build chamber’s temperature remains lower. Higher temperatures in the build chamber could theoretically raise the temperature of the toolhead’s cold zone enough to cause a clog.

The engineering series is a collection of plates designed for more general material use. One plate has a standard gold-colored PEI surface, and another has the same, but with zone lines imprinted on the surface. That could help laying out jobs with multiple parts.

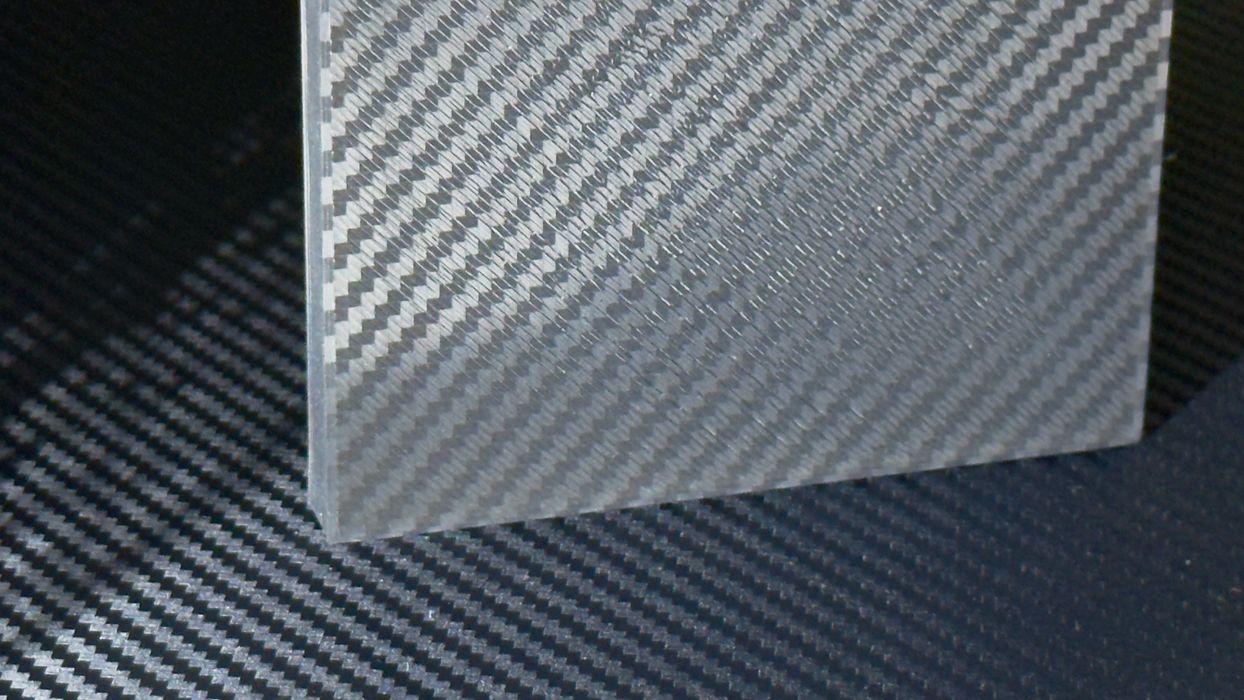

The other two plates are more interesting. On one side, they have the normal gold-colored, lined surface, but the reverse side has a pattern. One pattern has a repeating diamond pattern, and the other has a pattern quite reminiscent of carbon fiber.

These patterns are imprinted on the bottom layer of your print, and depending on the model, this could be quite attractive. Above, you can see the carbon fiber pattern, and here is the diamond pattern.

Panda Series Final Thoughts

The Panda Series is a set of very useful upgrades for selected Bambu Lab equipment. We found them all relatively easy to install, although doing the full set does take some time, and your machine will be down for a while during installation.

BigTreeTech provided excellent instructions for each of the upgrades, and it should be easy enough for almost anyone to follow.

The upgrades don’t provide individually revolutionary benefits, but they all contribute together to make the P1S (or whichever machine you’re using) to become quite a bit better. The cost of the upgrades is relatively low, making the decision to use them pretty easy, especially for the panel-deficient P1S and P1P machines.

This is part two of a two-part series; please read part one.

Via BigTreeTech