Our look at the resin pump system for the new Form 4L 3D printer concludes.

This is part two of a two-part series; please read part one.

Formlabs Resin Pump Operations

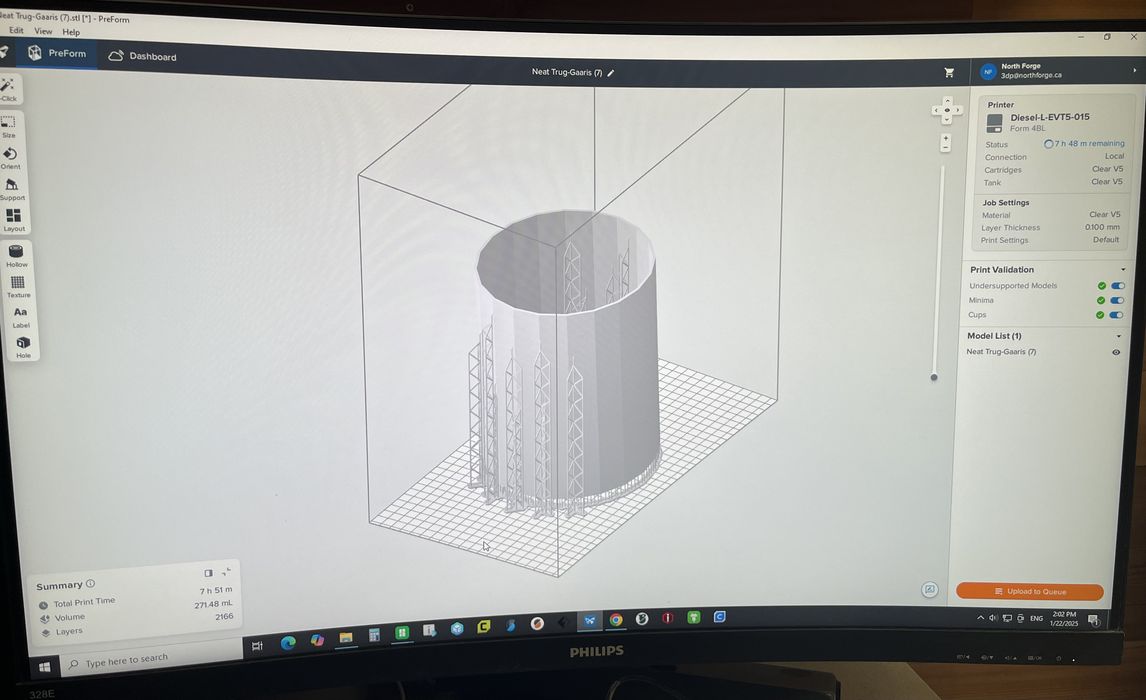

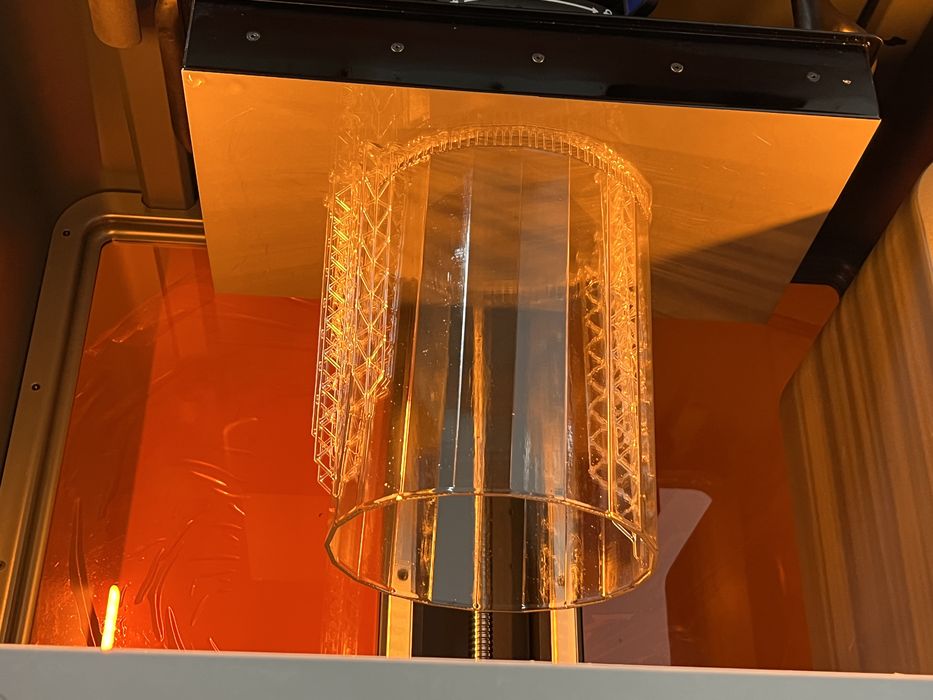

There is not really a way to fill the resin tank, aside from starting a job, so that’s what we did. We had 5L of clear resin and selected several models to print with it.

One concern we had was the speed of filling. Would the peristaltic pump be able to quickly fill the enormous 4L tank? It looked pretty slow at first, but in the end, it really wasn’t that much different than using a standard cartridge. As the filling took place, the 4L’s sweeper arm moved across and evened out the resin.

There’s really nothing special to do operations-wise with the resin pump installed. It’s as if you just have a larger cartridge: the machine keeps track of the usage and just runs longer.

With resin in the tray, the Form 4L operated quite normally; once the resin is out of the pump, it’s just like a typical Form 4L setup.

We printed several large items — and strangely had a couple of job fails. These were almost certainly due to misconfiguring the support structures on our part, so they didn’t have anything to do with the resin pump. The pump reliably kept the resin tank at the proper level for operation.

Formlabs Resin Pump Considerations

The Formlabs Resin Pump system works very well, but there are some considerations.

The big question we had was this: what happens when you want to change materials?

This is when we realized why Formlabs had designed a peristaltic pump system. The tube inside the pump carries the resin, and no resin touches the pump itself. This means that to change materials, you would need only to swap out that tube inside the pump, since it would be contaminated with the prior resin.

Formlabs suggests changing this tube when the resin changes — or after six months of use. It’s likely the tube begins to wear out after months of being squeezed like an intestine.

Two other components come into contact with the resin: the transfer tube and the transfer cap. If you intend on changing materials, then these three items will all be polluted with the previous material. They must be replaced, as explained by Formlabs:

“The pump tube, transfer tube, and transfer cap can only be used with only one resin type and cannot be reused when changing materials.”

Unlike resin trays, which are chipped and tracked, these components are not. That means you will have to keep track of them yourself somehow. Formlabs might consider including some sticky labels for this purpose? You’ll also have to find a secure place to store them, as they almost certainly will leak resin.

This is another reason to consider chopping your transfer tube: you won’t need to buy a second one. Formlabs does sell a “Resin Pump Maintenance Kit” for US$25 that includes the two tubes, but not a transfer cap. That’s sold separately for only US$5.

If you had ideas about using your Resin Pump for a variety of materials, you probably should order a few sets of tubes and caps to match your intended range of resin materials.

Formlabs doesn’t provide any information or tools for securely storing these resin pump parts after a material change. Trays, for example, come with a lid to cover them when stored, but there is no equivalent for the tubes and cap that are removed when material is changed on the pump.

This will almost certainly result in wet parts as they will drain when stored. Perhaps there is some way to print a mount that at least drains to one spot and keeps the parts mostly dry?

Formlabs Resin Pump Final Thoughts

The Formlabs Resin Pump system works extremely well, but is probably best used for production environments.

A Form 4L that’s regularly printing parts in the same material is the ideal scenario, as changing materials seems to be a bit troublesome. That said, it can be done if required.

Operations using multiple materials should recognize the spare parts required for long-term use and consider buying them in advance.

The cost of the 4L Resin Pump system is currently US$325, which might sound like a lot for a small pump. However, it’s set up to provide seamless operation on the Form 4L.

Another consideration is that for production environments, it will certainly save labor, as there would be 5X less effort required to change resin. In some cases, the cost might be the same as an operator shift or two, so the Formlabs Resin Pump is almost certainly a cost saver for larger operations, even over a short period.\

This is part two of a two-part series; please read part one.

Via Formlabs