Our review of the Formlabs Form 4L concludes with software, print results, and final thoughts.

This is part three of a three-part series; please read parts one and two.

Formlabs Form 4L Software

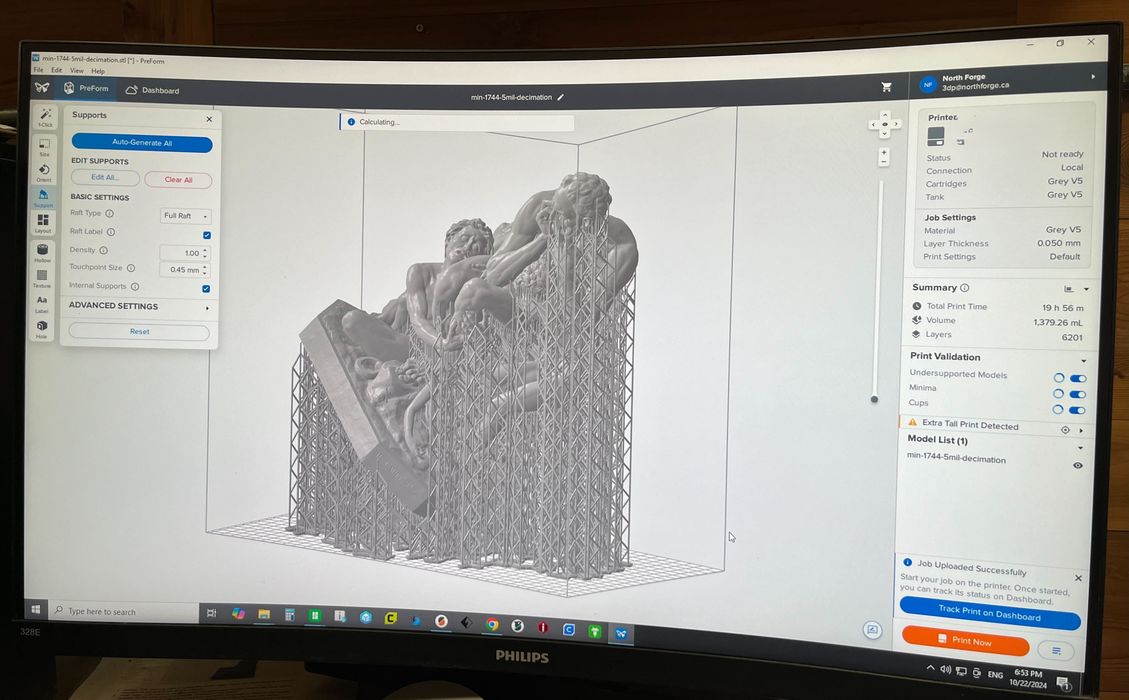

The crown jewel of Formlabs is their PreForm software, which is used to prepare jobs for all of their equipment, including the new 4L. It’s exquisitely designed and has the easiest workflow of any resin job software we’ve experienced.

Formlabs has carefully designed the user interface to not only ensure the operator doesn’t get into trouble but does so in an attractive and easy-to-follow manner.

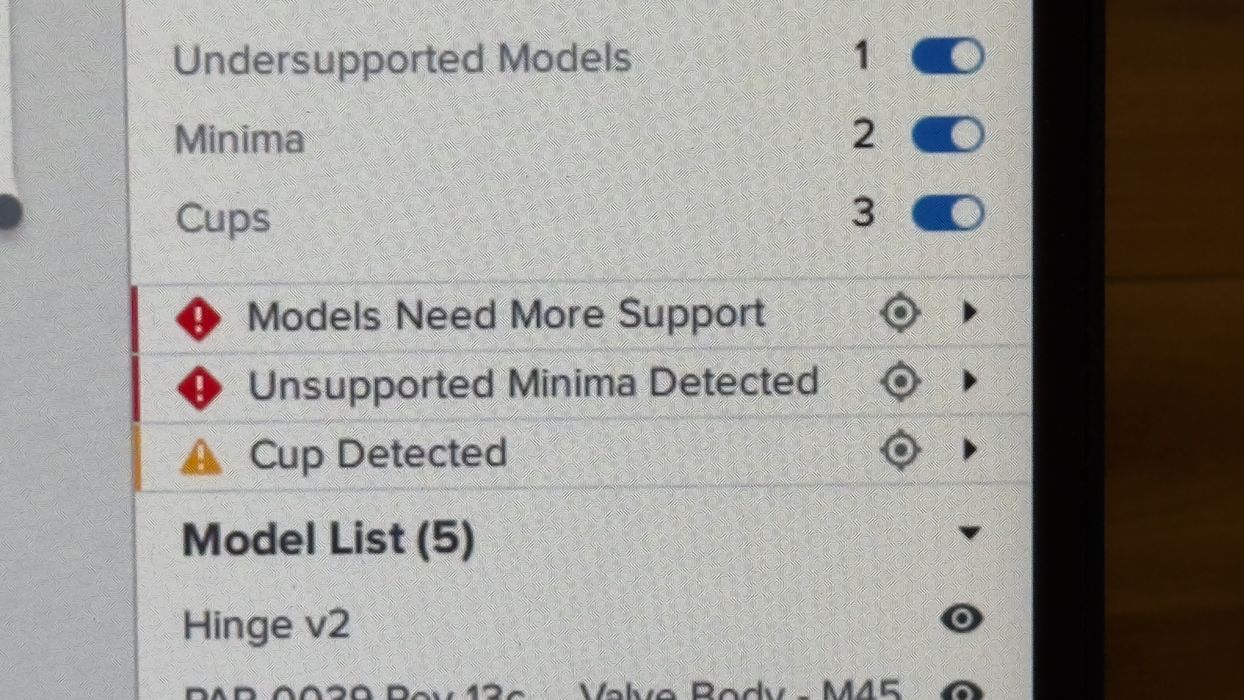

An example of this is shown above. PreForm analyzes loaded 3D models and presents error messages until the operator takes actions (like adding support structures) to get rid of the errors.

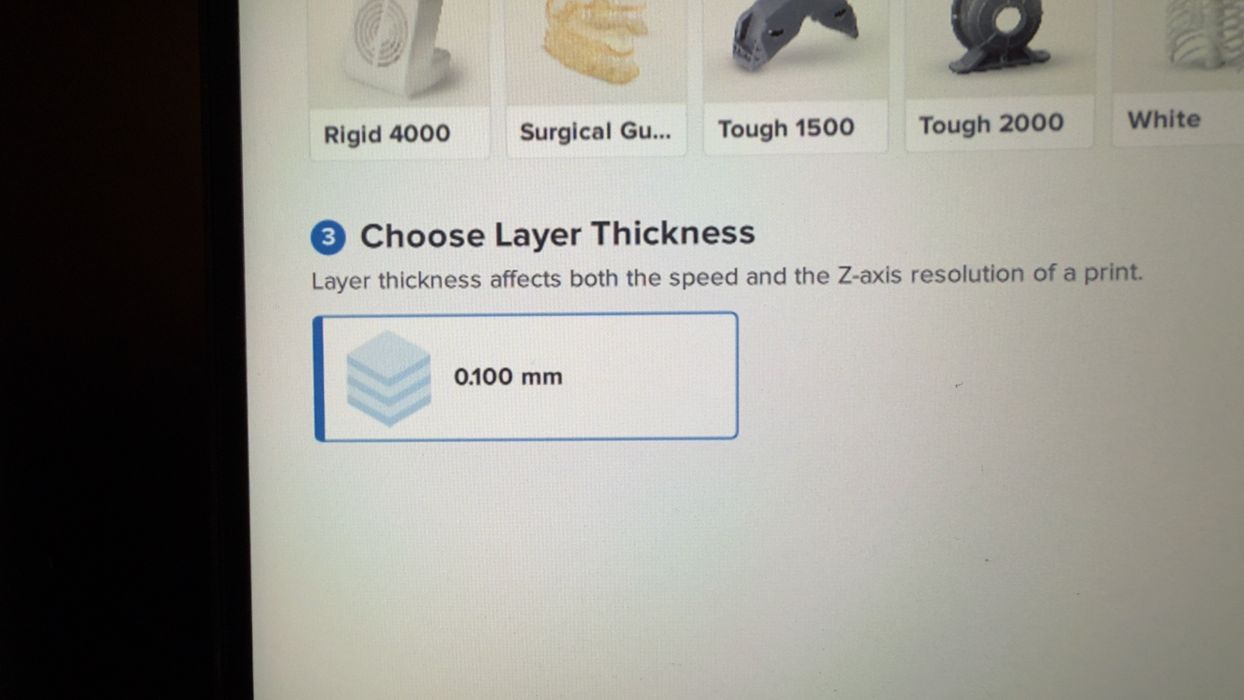

Here’s another example. We had been printing with the grey resin at 0.05mm layers. Then, switching to the high-speed resin, we found that PreForm would not allow layers of that size, presenting only a 0.1mm layer option.

This is done for two reasons. First, the print profile is tuned for only that layer size. But more importantly, why would you want to use the high-speed resin with a thinner layer? That would compromise the purpose of the high-speed resin, which is there to get prints done as fast as possible.

We had no issues with PreForm, and anyone that is using the software to run other Formlabs equipment will have zero problems integrating with a new 4L unit.

Formlabs Form 4L Print Results

We printed a number of different parts using different resins on the 4L. In general, we found the print quality to be very high and consistent among all the prints. This is quite different from the experience we get when swapping resins on other machines, where you end up recalibrating everything. On the 4L, it’s all automatic.

Large prints emerged from the 4L with visibly good quality, even when coated with wet resin. I believe that’s the case when you print larger items: the objects are larger, but the wet resin is the same thickness.

Here we see the same 3D model printed in the high-speed resin on the left, and standard grey resin on the right. The high-speed resin prints around 2X as fast, 5h24m vs 9h40m, but is quite a bit brighter. The grey seems to be more robust.

In the end, you’ll have to decide on the priority for your work: do you need the print done faster? Or do you need the strength of the grey resin?

We usually print the Nefertiti 3D model on resin tests, and did so with the 4L. As expected, it was near perfect in grey resin.

Another 3D model we often print in resin is the Mayan Calendar Wheel. It includes an impressive level of fine detail, ideal to show off the capabilities of a machine.

The wheel came out perfectly, and, unlike several other machines we’ve recently tested, had a perfectly flat reverse side. The concept here is that PreForm does an incredibly good job on automated supports, which ensured the part was geometrically accurate.

We also shrunk the wheel down to see if we could squeeze out more details, and the 4L did reasonably well. However, this machine is really designed for large parts: if you want highly detailed smaller parts, why build a giant 3D printer?

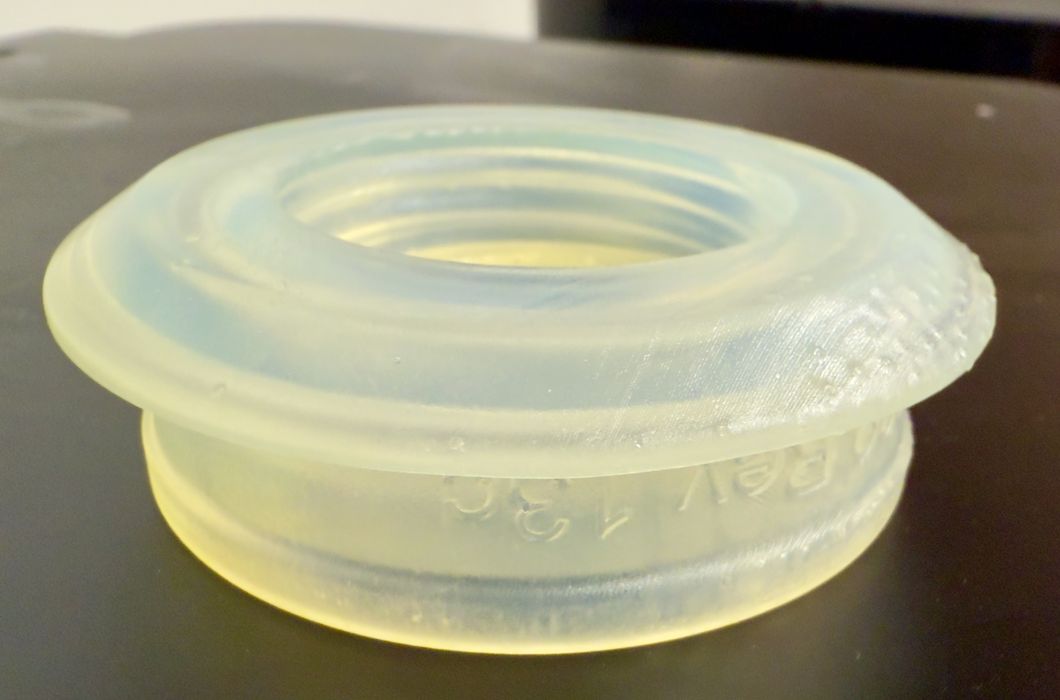

We moved on to the durable resin. We printed this component for an experimental respirator system, and it came out in near-perfect condition. The part fit the application correctly.

We did notice that the durable resin, although noticeably stronger, was quite transparent. Here you can see through this miniature turbine blade we printed during our test.

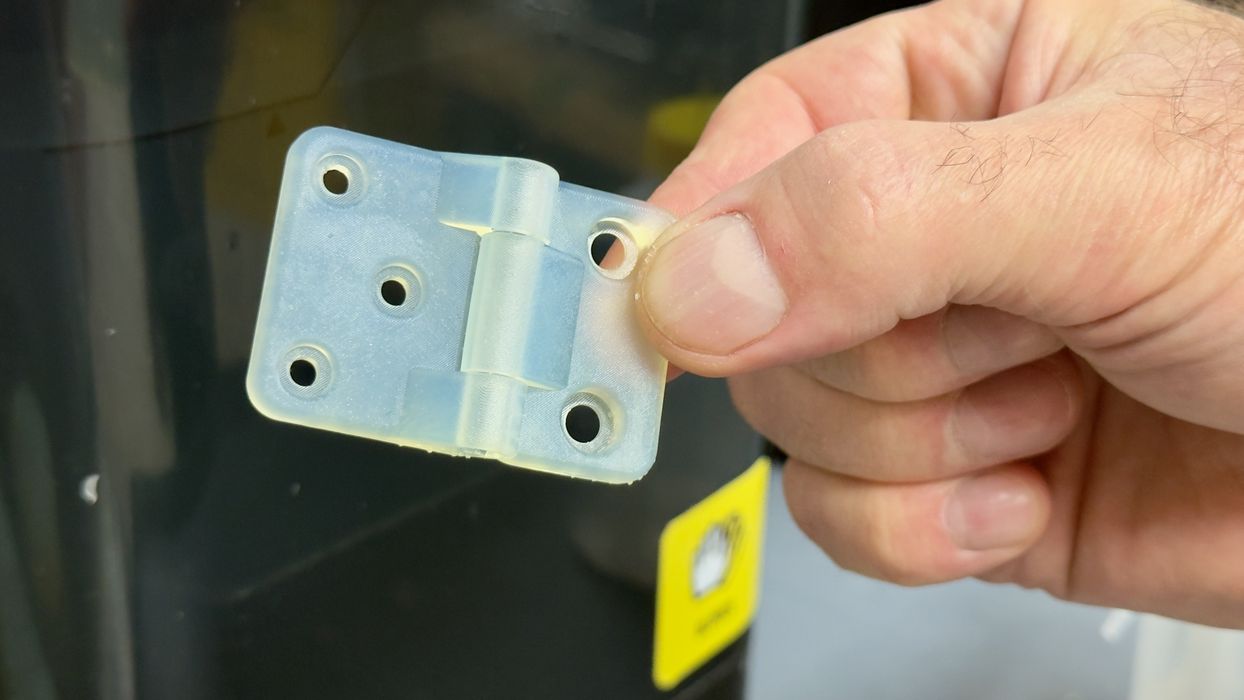

We printed a small hinge to test the ability of the 4L to separate parts, and the hinge was printed correctly. It should be quite possible to print articulated parts on the 4L.

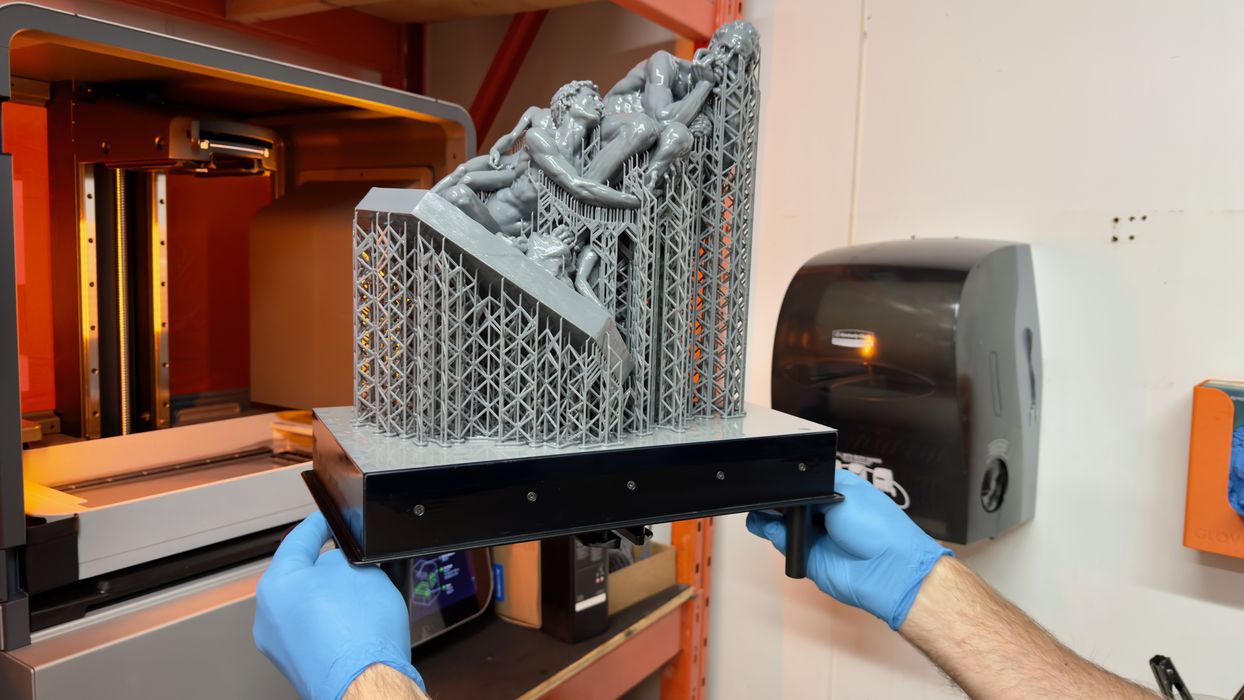

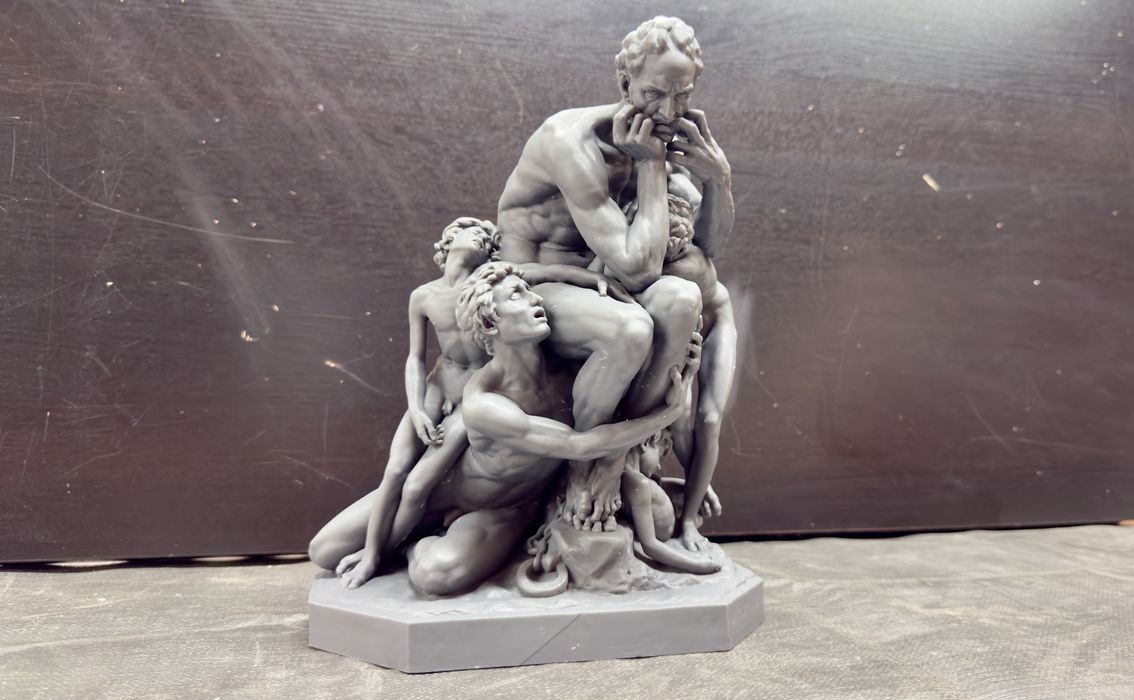

Back to the Ugolino sculpture. This item required a great deal of support structures, as you might imagine with its complex geometry. However, because of the excellent support structure tips, they were easily removed, and the sculpture came out quite beautiful.

The Ugolino sculpture was quite large and required a considerable amount of resin. Because of this, the 4L ran out of resin during the overnight print and waited for us in the morning to pop in another resin bottle.

When the job was completed, we did notice a very slight line in the print, shown here. This seems to be the transition between pause and restart of the job when waiting for resin. There didn’t seem to be a significant surface difference, but we’re not quite sure how this is happening. However, if you’re expecting perfect surface quality when jobs pause, then you should be aware this can happen.

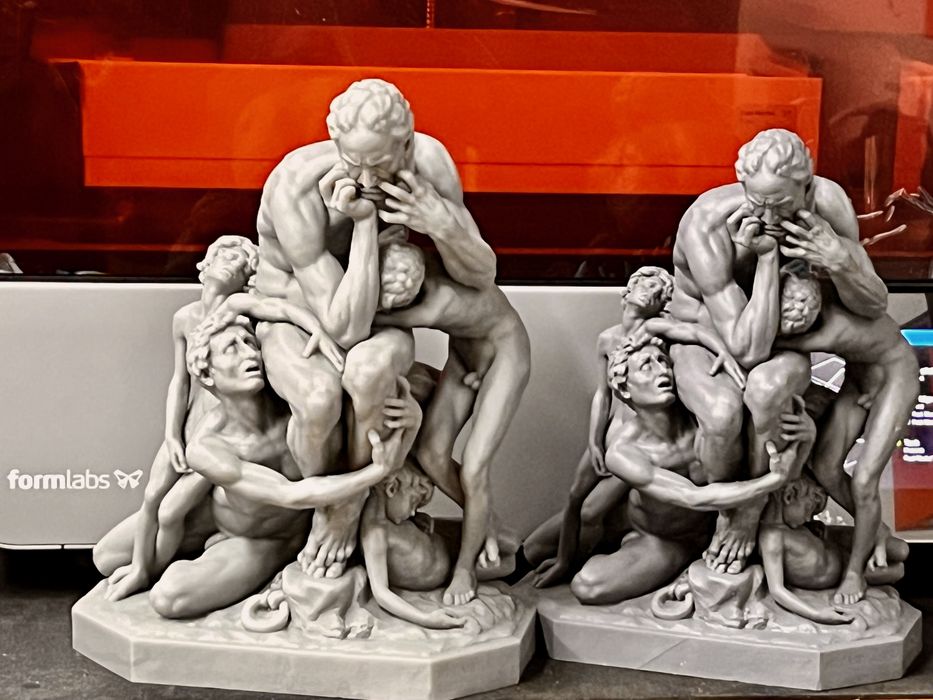

We printed the Ugolino sculpture twice, once with the grey, robust resin, and the second time with the high-speed resin. The high-speed resin is more bright, so it’s easily recognizable on the left.

The sculpture printed much faster with high-speed resin, only 8h vs 20h, 2.5X faster. And that’s even with making the sculpture a bit bigger — we found another angle to tip and stretch the sculpture in the build chamber. Part of the speed difference is due to the larger layer size, but there’s also a boost from the chemistry of the resin.

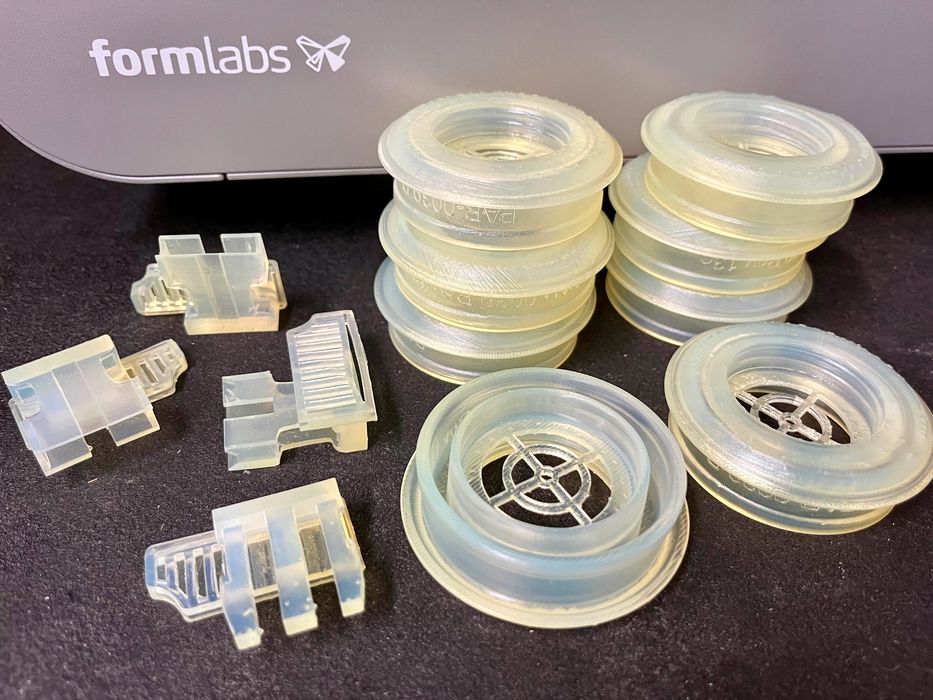

The large build volume permits not only printing large single objects but also large batches of parts. We did a big batch of respirator parts to more or less fill the build plate.

They all printed correctly, as shown here. It’s pretty clear that you can easily use the 4L as a low-volume production machine to quickly pump out quantities of parts. This is especially true if you have an array of 4Ls, which I’m sure some will do.

We printed a series of random mechanical parts in the durable material to see what happened. Some parts were robust, but others had delicate features. There’s not much to say; they all were produced perfectly.

Formlabs Form 4L Final Thoughts

The Form 4L is quite an incredible resin 3D printer. It is a complete system that integrates materials, hardware, and software to produce a truly end-to-end workflow experience that just works. We had not a single print failure, and indeed all prints came out perfectly.

This is not the experience you will have on most inexpensive resin 3D printers, where there are calibrations, failures, and most especially, fighting with support structures to get them correct. On the 4L system, PreForm seems to generate perfect support structures every time. Normally, we don’t trust generated support structures, but the 4L’s automated supports gained our trust with repeated print successes.

There are several materials available for the 4L, and they are not unreasonably priced. The grey resin, for example, is priced at only US$79 per bottle. That’s a bit more than cheap resins, but they require testing and calibration, which all waste material. The Formlabs resins just work.

The Form 4L is a bit more expensive than typical inexpensive desktop resin 3D printers, but for that price, you get a machine that’s almost guaranteed to work, is very high speed, and consistently produces high-quality output. It’s also less expensive than many high-end resin 3D printers that may not have all the features available in the 4L and its ecosystem.

Who should buy the 4L? This is definitely not a machine for beginners or hobbyists. Anyone that doesn’t want to fuss with settings and just wants very good quality results — either for large objects or for low-volume production. If those are true and 4L is within budget, then it’s an easy choice.

FORMLABS

FORM 4L 3D PRINTER

★ BEGINNER 5/10

★ ENTHUSIAST 9/10

★ PRODUCTION 10/10

BEST FEATURES

✔︎ Consistent quality

✔︎ Large build volume

✔︎ Easy operation

QUESTIONS

✖︎ Price level

✖︎ Pause defect

✖︎ Tray storage space

This is part three of a three-part series; please read parts one and two.

Via Formlabs