Our review of the world’s fastest desktop 3D printer, the FLSUN S1, concludes with software, print results and final thoughts.

This is part three of a three part series, please read parts one and two.

FLSUN S1 Software

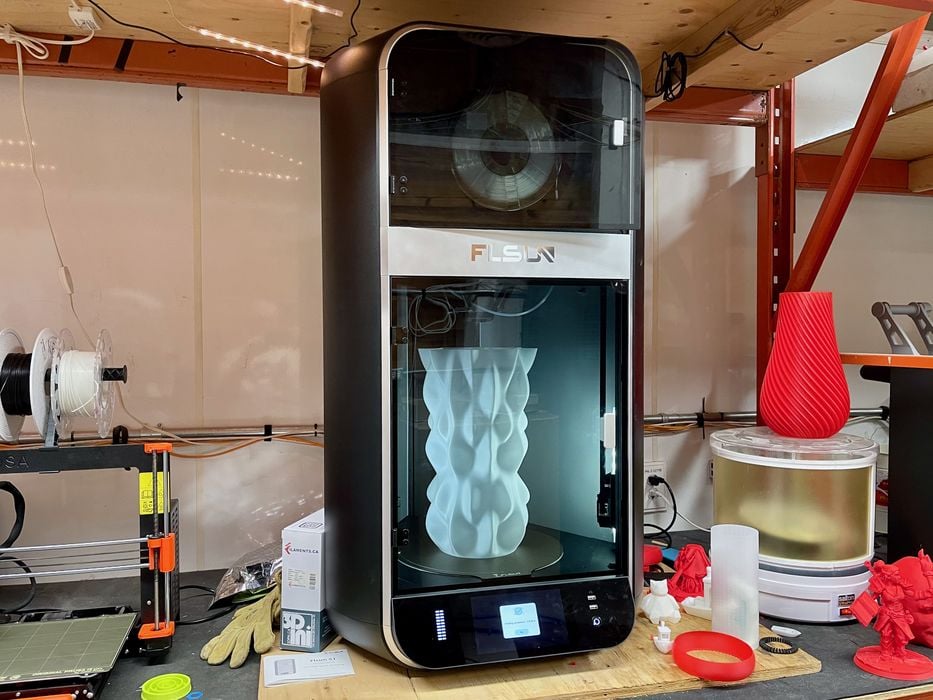

Software for the S1 is the FlsunSlicer, which is available for Windows and Mac OS. It’s based on the PrusaSlicer/OrcaSlicer stack, so its usage will be quite familiar to most 3D printer operators.

The difference is that FLSUN has baked in features to allow job dispatch to the S1 over the network, as well as realtime job monitoring and control. In the image above, note the “Send G-code” button, which can start a job remotely. You can, of course, also do the traditional manual procedure with a file.

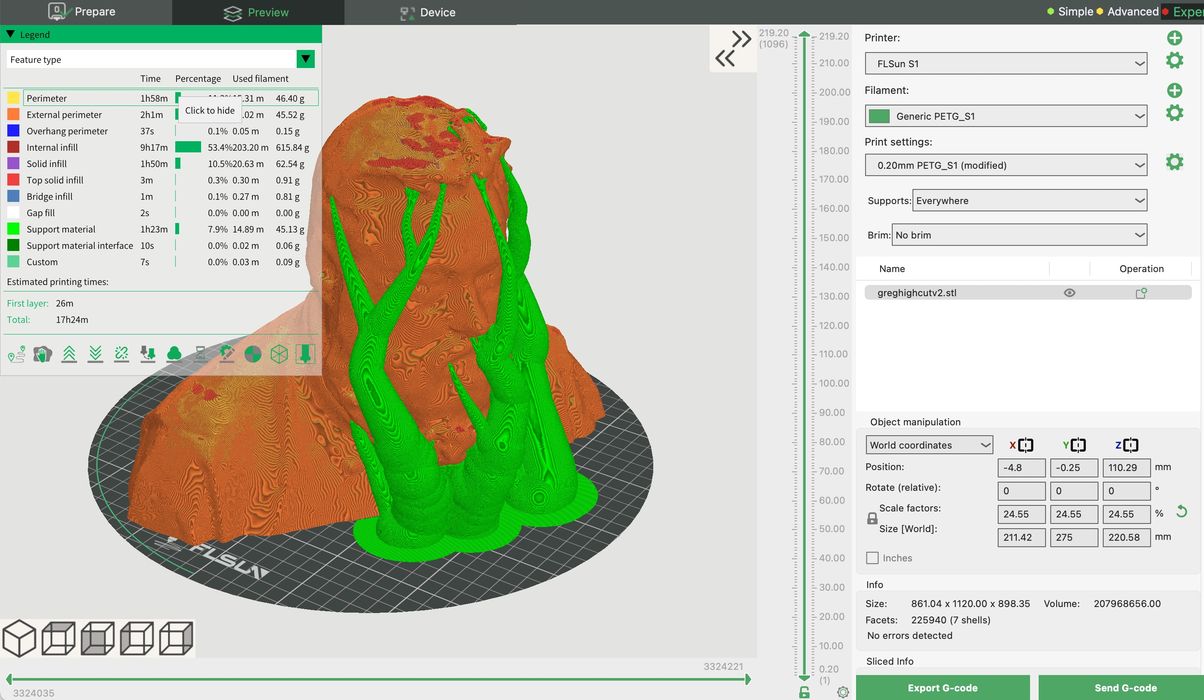

When printing the huge Lumpy Bumpy Vase at nearly the specified maximum build height, we had a very unusual problem. When printing near the top of the build volume, the S1 complained:

“The printed model exceeds the maximum limit and printing fails”.

The option presented was a single button saying, “Yes”. I guess that is like “OK”, or “Continue”, but this is another example of strange wording on the S1.

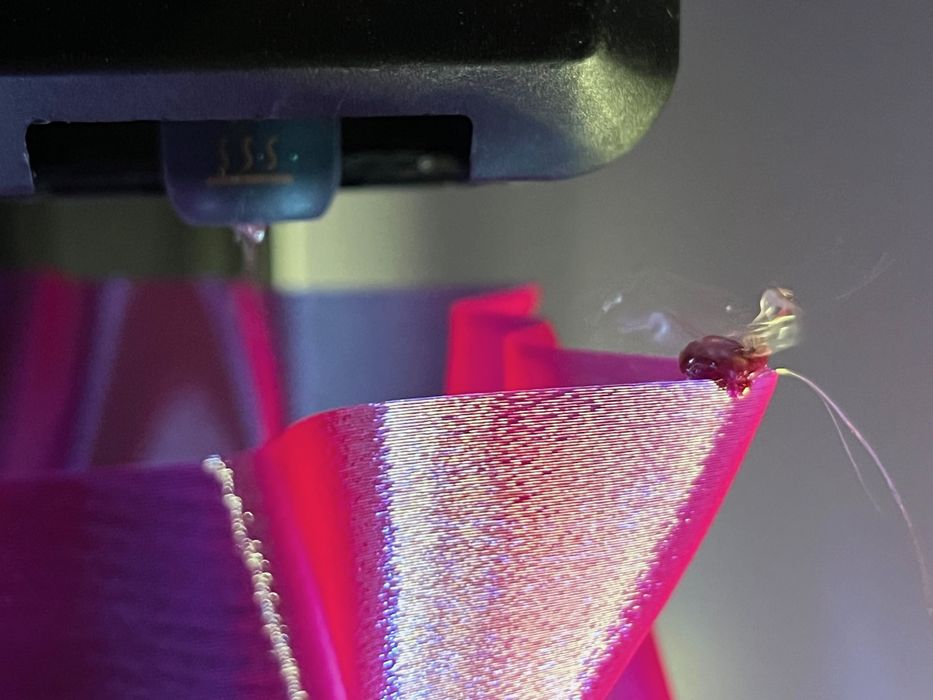

The machine just stopped. Here you can see that the S1 remained at temperature, with fans blowing full, on this spot. This caused a bit of a blob in addition to halting the job. In this situation the S1 should really have shut down the temperature and later the fans. Our S1 ran overnight in this condition.

But why would the machine fail because the model was too big? We had specifically set the height of the model to be 5mm lower than the maximum specified build height.

It turns out, after discussions with FLSUN, that the build volume is NOT a perfect cylinder. The top of the build cylinder varies depending on where the toolhead is located. That’s due to the nature of the delta motion system. Delta operators would know this, but we didn’t, and those new to delta motion systems will almost certainly bump into this issue.

We did some measurements, and with the machine turned off, we could manually move the toolhead around to “feel” where the top really exists. It turns out that there are low points directly under each of the three axes, and not-quite-so-low points inbetween the axes. The maximum build height is achievable only above the center of the plate.

This all makes a great deal of sense, but the problem is that FlsunSlicer did not detect this. We did several experiments with different heights and shapes, and found it’s easy to get a valid slice, but an invalid print job. The slicer should be adjusted to account for the varying build height limits. However, that’s probably complicated because the actual build ceiling is a warpy curved surface that might be challenging for software detection.

Finally, here’s another strange user interface message we observed. This is the standard display when you’ve send a job to the S1. We can “Start” the job — or “No”. Does “No” cancel the job? Or pause it? The machine is already idle, so what does this do? Unsure here. Operator panels should not be ambiguous in any way.

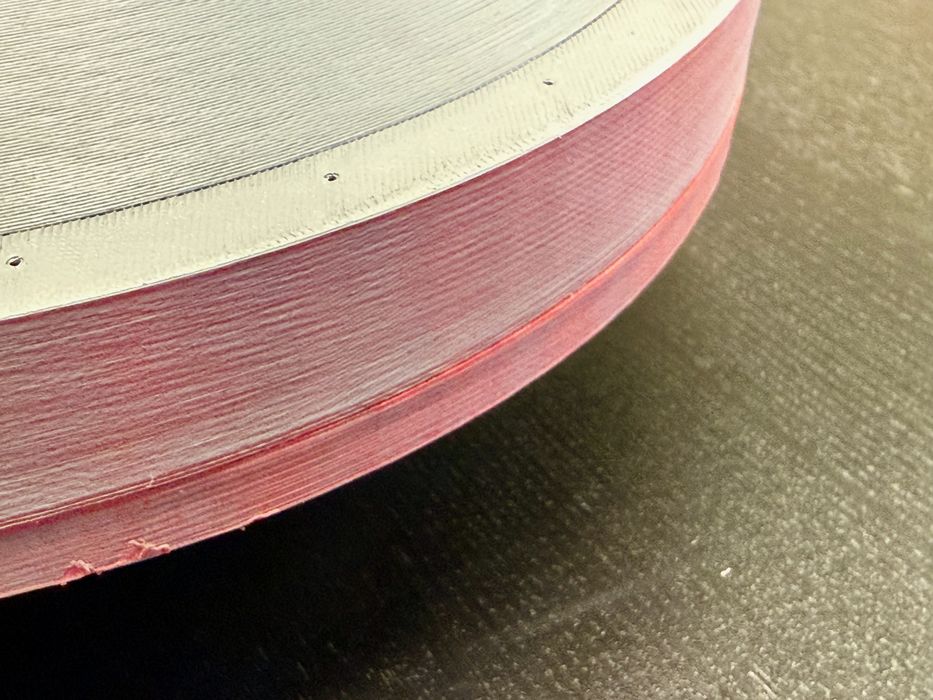

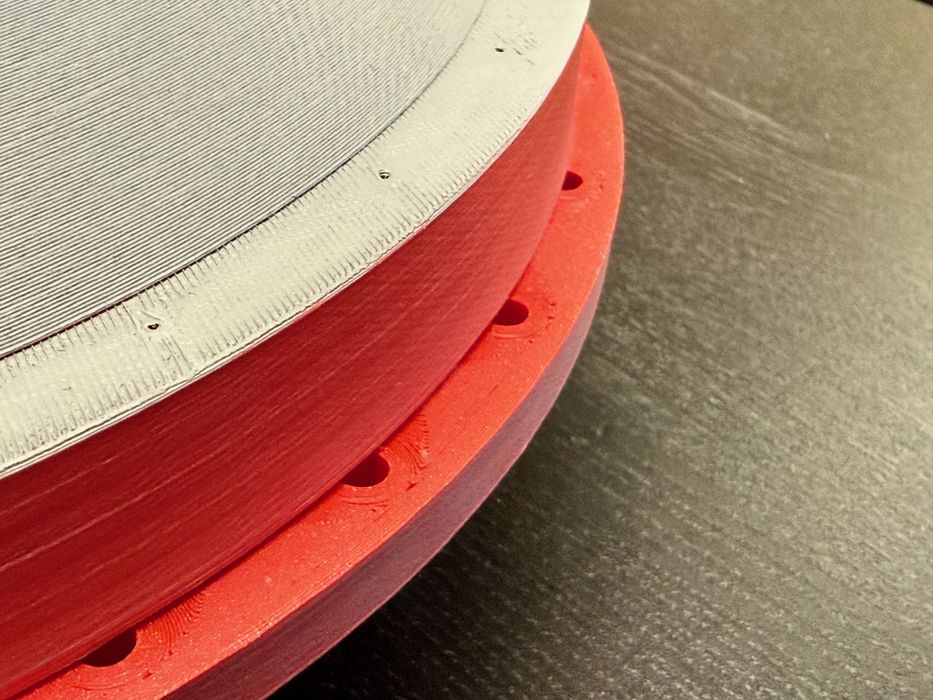

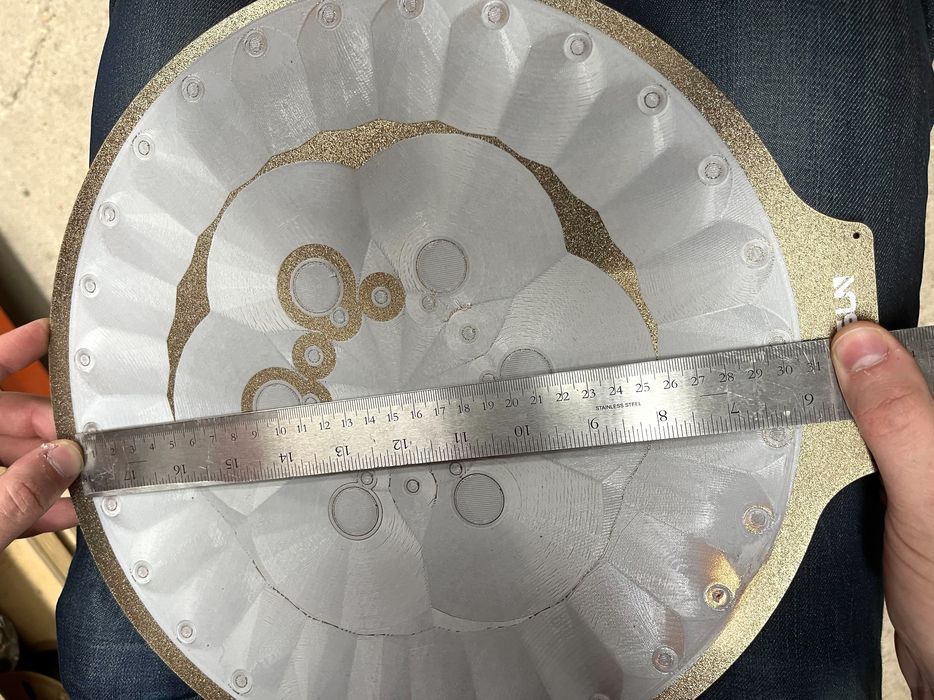

We encountered a very unusual problem when printing a large circular part with diameter 315mm, about the maximum for the S1. Two parts were printed, and we stacked them together as you can see above.

However, on the other side of the stack, the supposedly identical diameter circular parts were not aligned!

This was a bit concerning, as we then suspected the S1 wasn’t producing properly dimensioned parts. We performed a series of experiments with circular prints to identify what was going on.

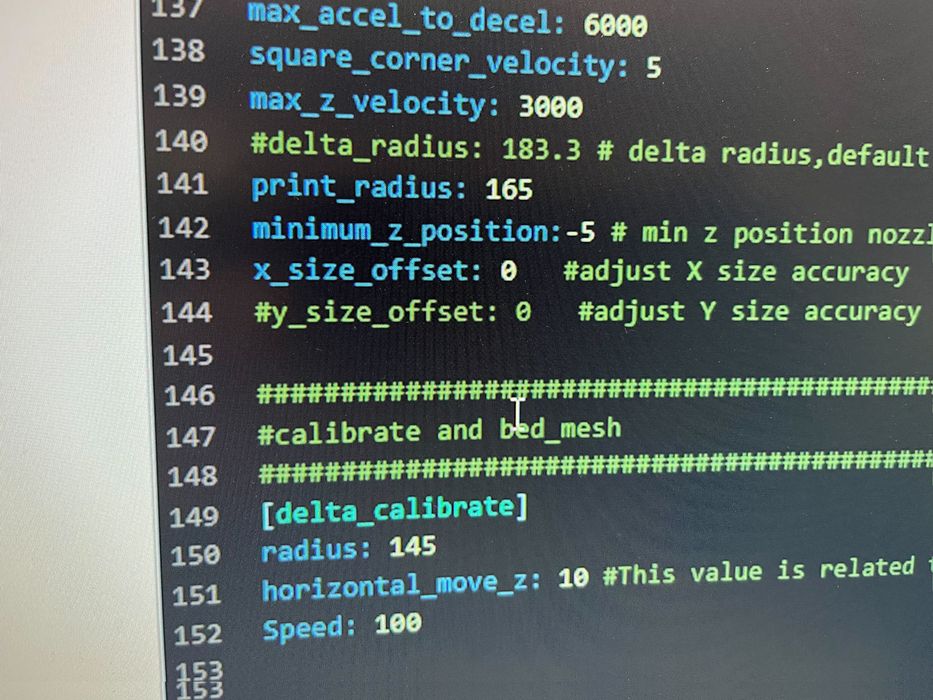

In the end we found that in the FlsunSlicer printer.cfg file, the offset adjustment for the Y-axis was commented out in FlsunSlicer V2. Because of this the offset used was unpredictable, possibly resulting in the dimensional problem. We un-commented the Y-offset value, and now the printer is producing true circles. If you’re having this problem, check printer.cfg.

FLSUN S1 Print Results

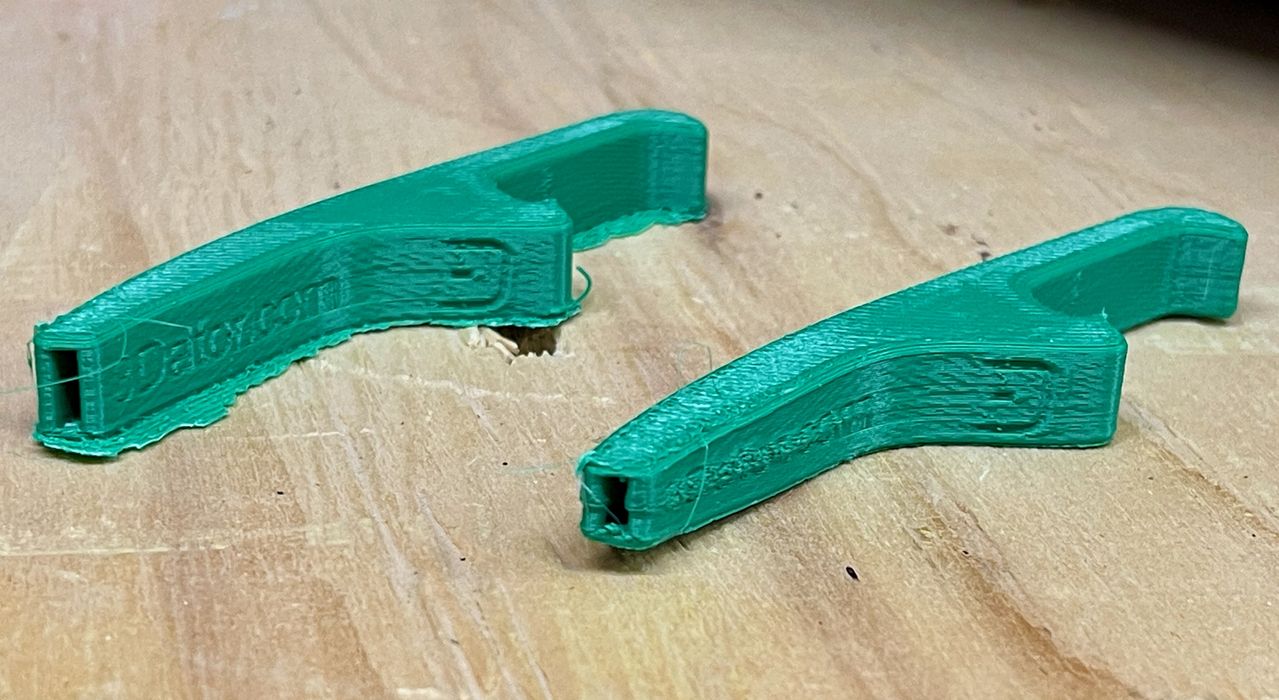

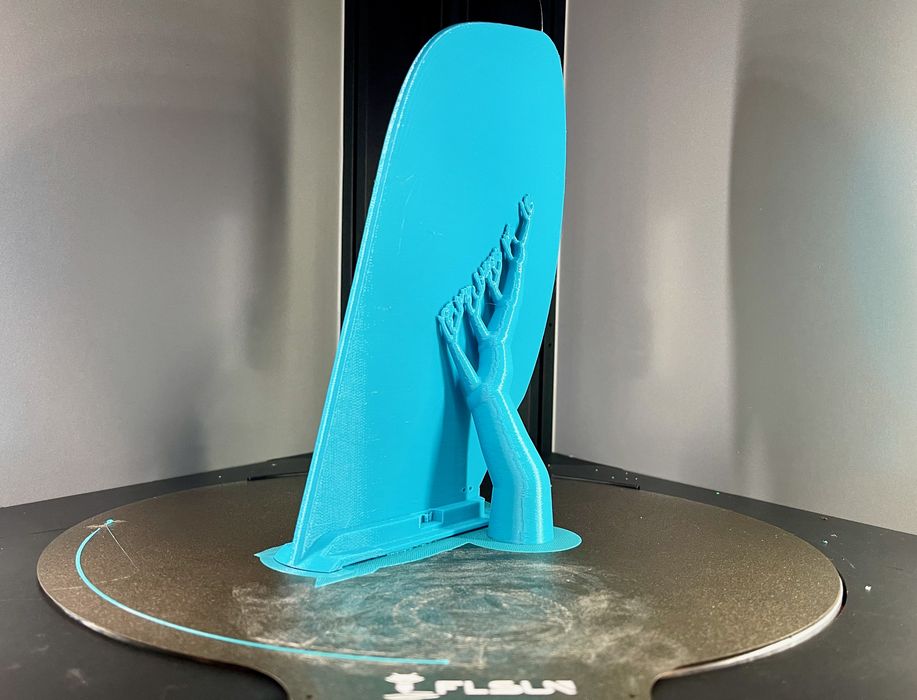

Print results were generally very good on the S1. Here we printed a gaming figurine at super scale to see how well it would work.

Unfortunately, while the print itself was terrific, the support structures were tightly bound to the model. This is likely because the print profile doesn’t leave a sufficient gap between the support and the model, at least for the material we were using. It’s best you do some tuning of this before committing to a large job, as we actually ripped the arm of the figurine while cleaning up the supports.

All was not lost as we were able to complete the cleaning and repair the broken arm.

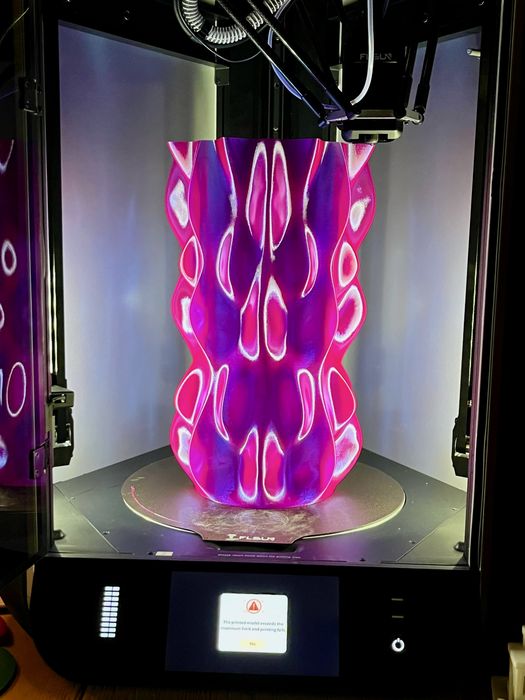

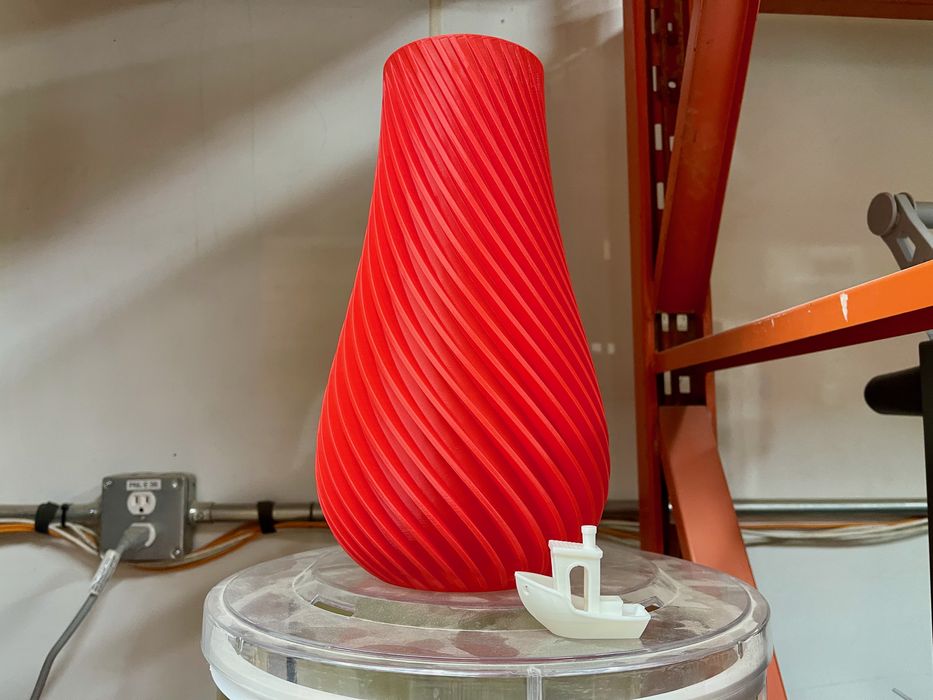

We printed a very tall vase with the S1 and it came out near perfect. The layers adhered very well, and we were even able to bend the vase somewhat without breakage.

Testing ABS was warranted as the machine supports this material and it has an enclosure to assist with warping.

We found that ABS material could indeed be printed, if you had a sufficient brim on the model. The quality wasn’t quite as good as PLA, but that’s largely because ABS is a bit trickier to print. It’s likely that some profile tuning could clean this up.

Here you can see a comparison of with and without a brim. The no-brim print did warp slightly.

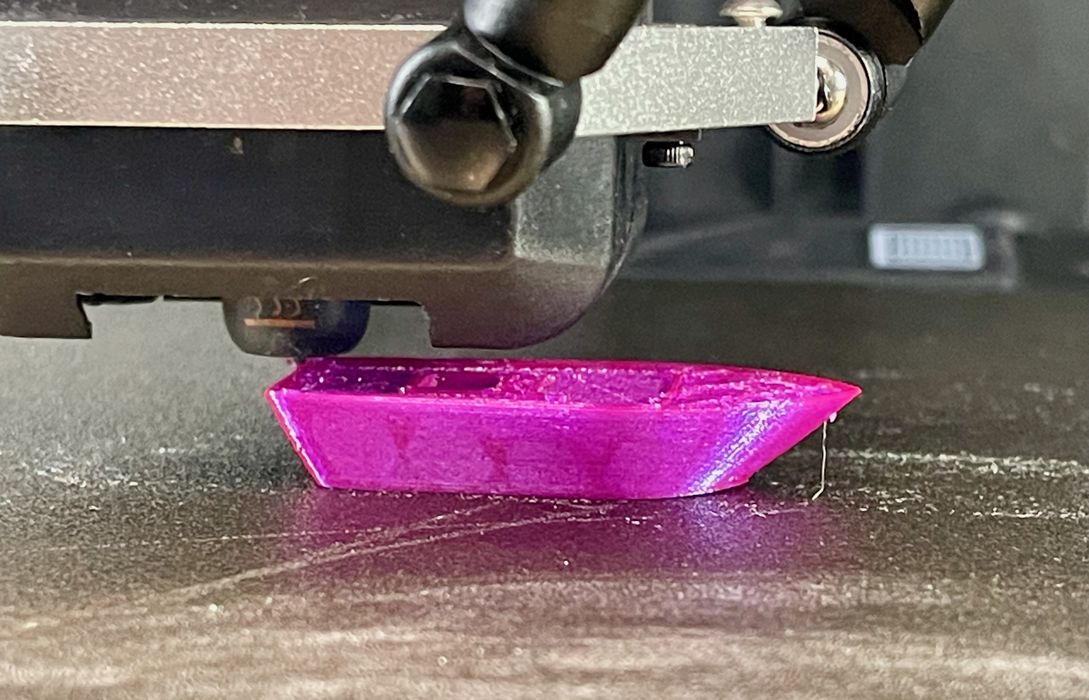

PETG prints wonderfully on the S1. We were able to print a #3DBenchy that came out perfectly. However, we could never achieve the 8m print duration with our own slices, as FlsunSlicer doesn’t seem to have the same high speed profile. Even after playing with print speeds, we just could not get the fastest speeds on our own.

Here you can see how well PETG prints on the S1, with a perfect first layer.

Would TPU print well on the S1? TPU is a very challenging material to print, and it turns out the S1 is easily able to handle it. We printed this stretchy bracelet and it had great quality.

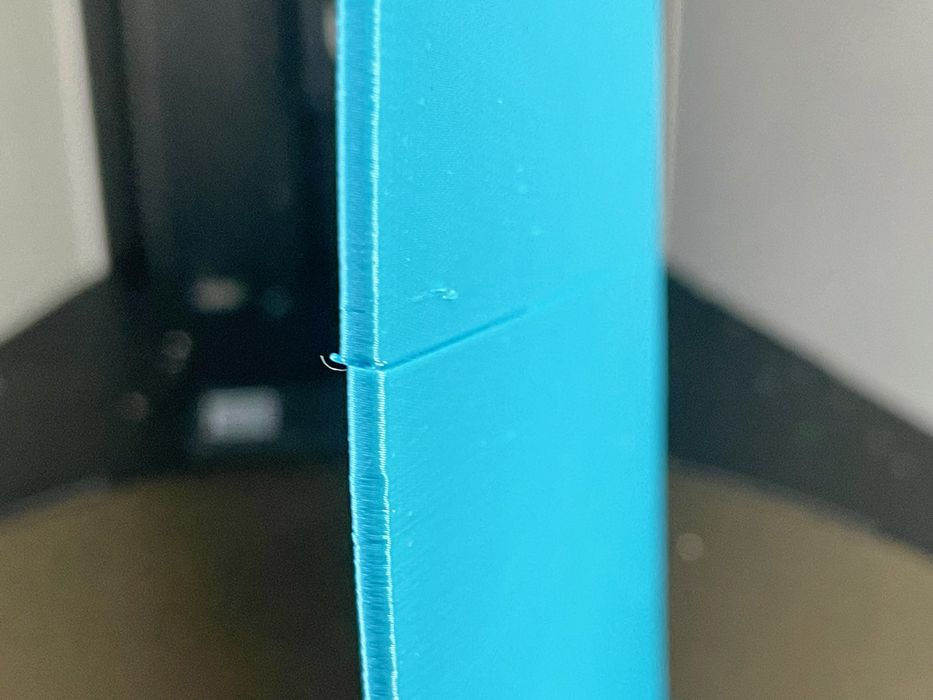

We tested Fiberlogy’s PCTG, a rare 3D print material that’s similar to PETG, but a lot better. FlsunSlicer did not have a profile for it, so we went with a tweaked PETG profile. It seemed to work very well, except that we encountered a very slight layer shift way up the print. This isn’t due to the print moving, as is the case on bedslingers. On the S1 the print remains stationary.

A second attempt was quite successful with PCTG, and we were able to print a functional kayak skeg — which was later used on the water.

FLSUN S1 Final Thoughts

The FLSUN S1 is really a terrific 3D printer. It’s large, it’s fast and it’s enclosed. It can easily handle a wide range of 3D print materials, and is pretty easy to use.

The ability to dispatch jobs remotely was very convenient, and we used that method constantly. There were some quirks in the slicing software, but nothing that would prevent normal use.

We did encounter multiple instances of language translation problems. None of these were catastrophic, but perhaps FLSUN might review them before their next firmware release.

The FLSUN S1 is priced a bit more than other high speed 3D printers at US$1,499, but that is quite reasonable considering that it can print almost twice as fast. That’s like buying TWO slower printers at a discount. In addition, the S1 has an enormous build volume for larger prints.

The S1 might not be a machine for beginners due to its power and price, but is very suitable for professionals and even low volume production.

FLSUN

S1 3D PRINTER

★ BEGINNER 7/10

★ ENTHUSIAST 9/10

★ PRODUCTION 9/10

BEST FEATURES

✔︎ High speed

✔︎ Print quality

✔︎ Large build volume

QUESTIONS

✖︎ Language usage

✖︎ Spool mount

✖︎ AI detection

This is part three of a three part series, please read parts one and two.

Via FLSUN S1