Our look at the Elegoo Centauri Carbon desktop 3D printer concludes with print results and final thoughts.

This is part three of a three-part series; please read parts one and two.

Elegoo Centauri Carbon Print Results

We went through some of our regular review prints to get a feel for the Elegoo Centauri Carbon.

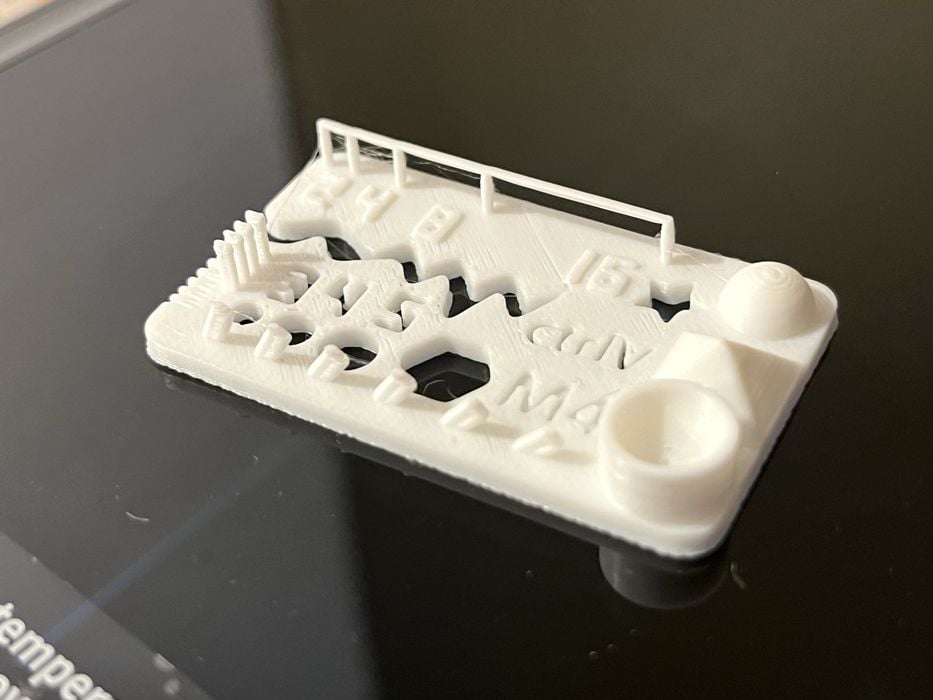

The CTRL-V print took 12:11 to complete in Balanced mode and 11:20 in Ludicrous mode. It’s too small of a print to see any real reduction in time when printing in Ludicrous. We decided to print in Balanced mode until we got to something larger.

The XYZ calibration cube finished in 9:18, and the Knurling Nut & Bolt in just 41m. All prints had fantastic surface quality, and the knurling nut & bolt spun together with no effort whatsoever.

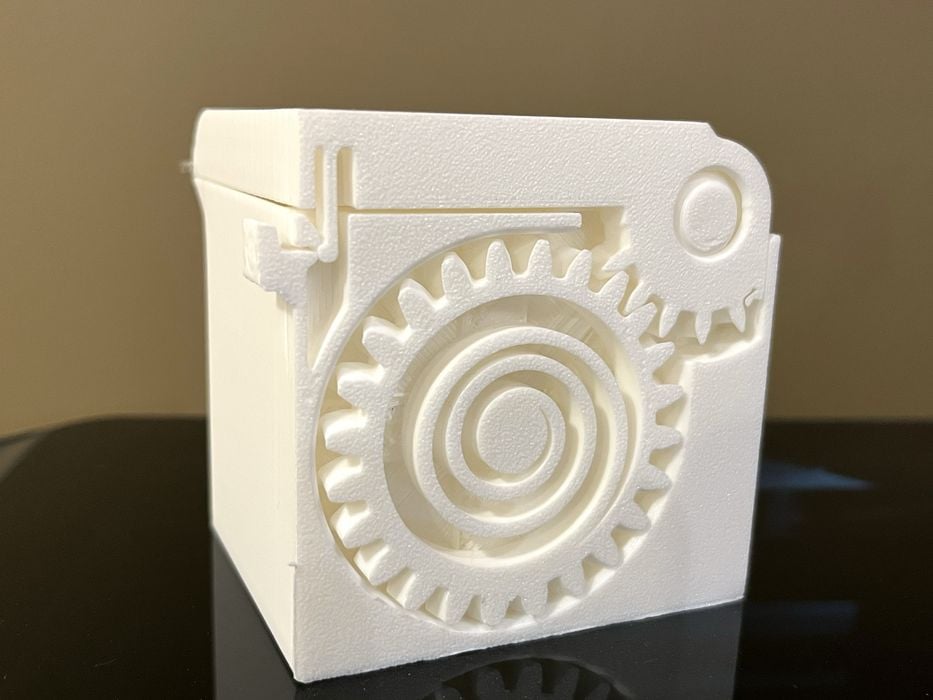

The PIP-spring-loaded_box printed in 1:53:00. The slicer automatically added a brim to the print, as it contained some delicate features that might have failed without it. The completed print had a great surface finish and articulated as designed.

The Planetary_gears 3D model completed in 1:35:00 and immediately articulated perfectly after removing it from the build plate, with no wiggling or jiggling required to coax it into working. That’s quite a feat given the experience we’ve had with this 3D model on most other desktop 3D printers.

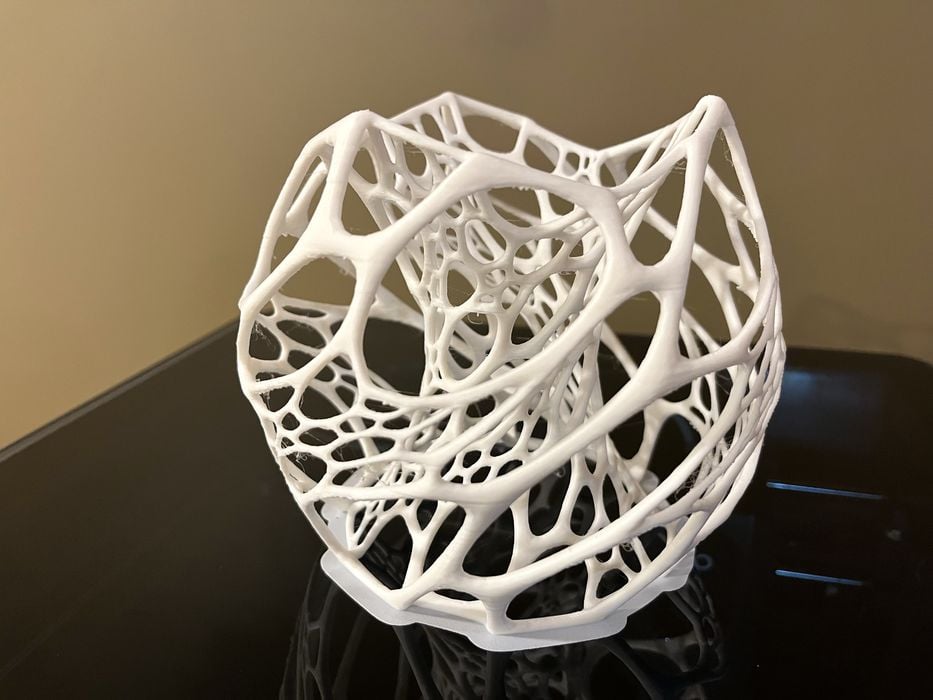

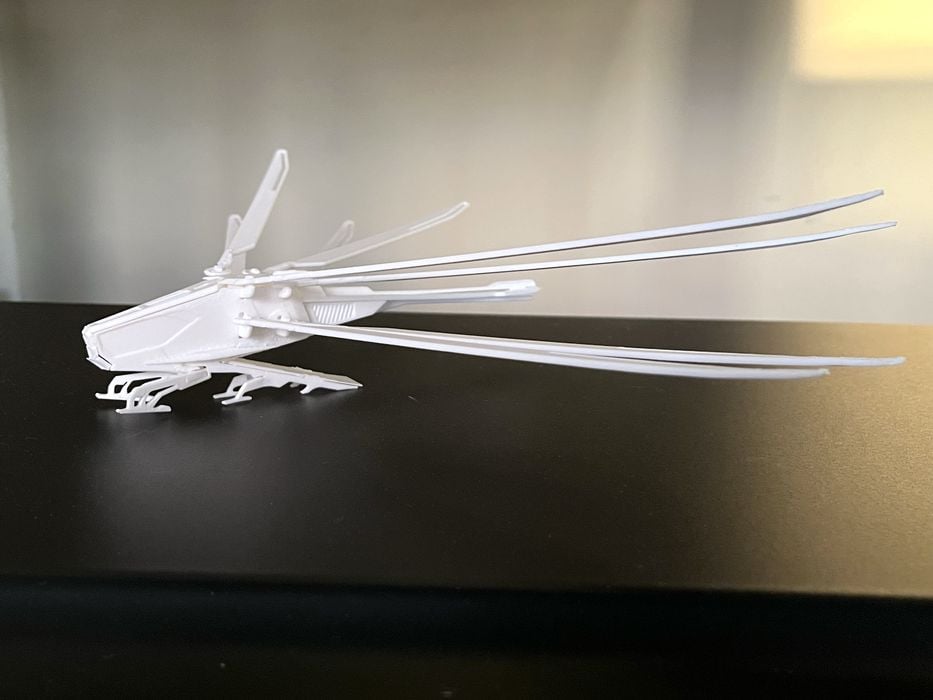

The Nervous System lamp completed in just 6:03:00. There were no segment failures, and the build quality was quite good, with the exception of a bit of stringing.

Elegoo included a roll of their galaxy black PLA branded filament for use with the review, so we switched to that for the Spiral Vase. Scaled to maximum size in the slicer, it printed in 3:26:00 with excellent quality. Out of curiosity, we reran the print in Ludicrous mode, which completed in 3:08:00, with print quality being identical.

It seems that Ludicrous mode is faster, but only slightly. The benefit likely depends on the geometry of your 3D model.

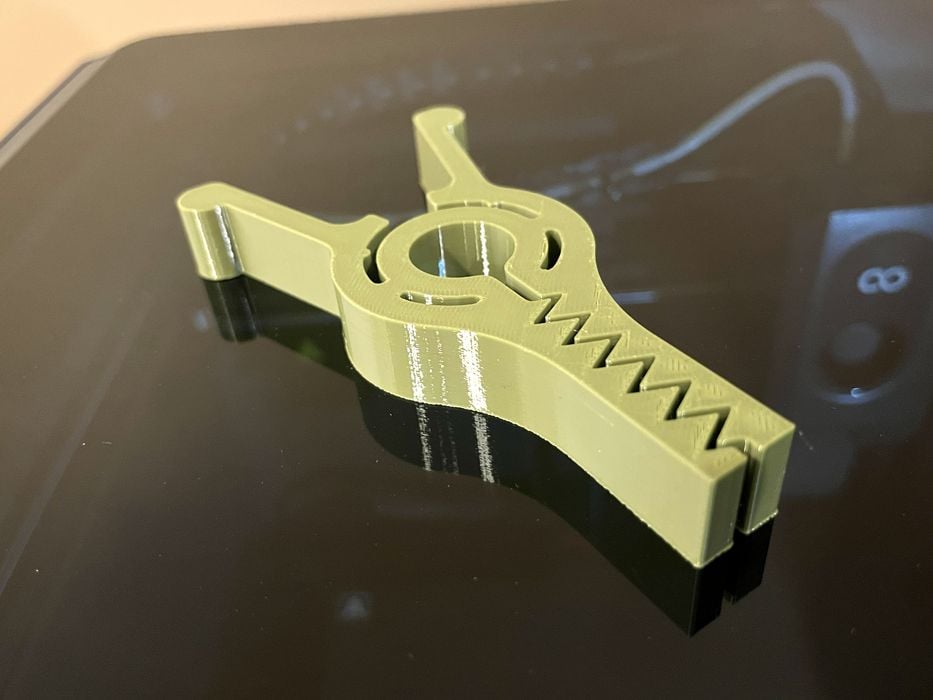

We switched to standard PETG filament for the Chip Bag Clip test. The only filament choices in the slicer were Elegoo PETG PRO or Elegoo RAPID PETG. We went with PRO and sliced our file. There wasn’t a PETG process to choose from either to adjust for speed, etc., but we saw that the volumetric speed limitation in the filament profile was much lower than PLA, so we knew we should see slower print speeds than PLA. Print time was 49:10, and surface quality was fantastic, with the print articulating very well.

We swapped out filaments again to print Bottle Opener Whistle, sliced with ABS and default settings for Process, and added a brim for good measure. The print was successful and looked great with no warping. This shows that the enclosure does help considerably with printing ABS and similar warp-prone materials.

We switched to TPU 95A and used a matching filament profile and again paired it with the standard process for 0.20mm. TPU can really stick to a build plate, so just to be safe, we applied some glue stick in advance to the plate to avoid any issues. The print completed successfully in 32:25, was very flexible, and looked very good.

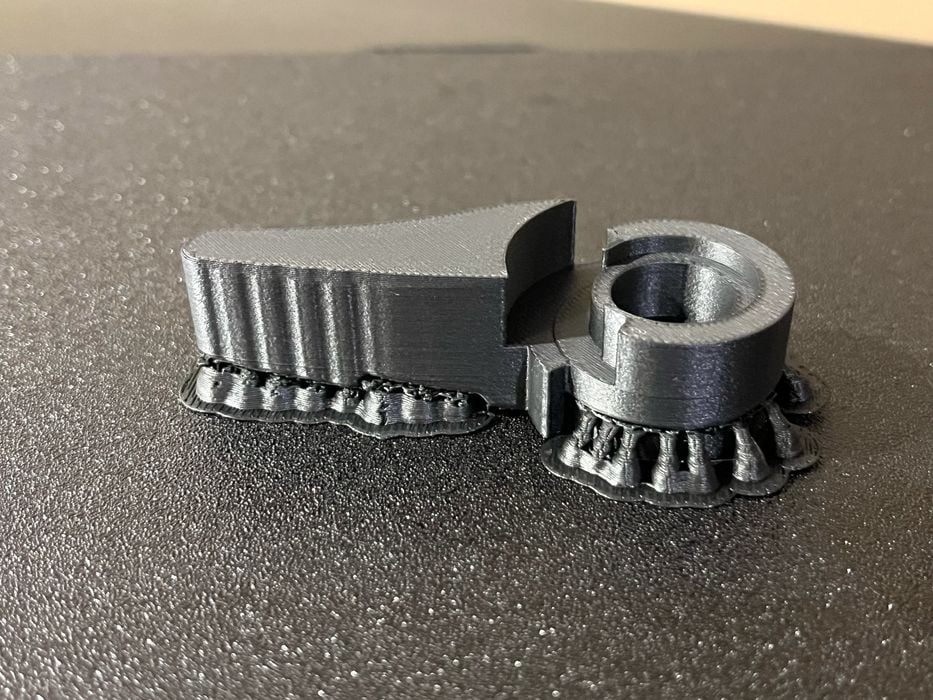

We switched over to some carbon fiber PLA to print a detailed mechanical part – a Gear Shifting Knob for a bicycle, enabling tree supports to help out with a few complicated areas. The print completed successfully in 42m with supports pulling off very easily, and the overall print quality of this model was fantastic.

Elegoo Centauri Carbon Final Thoughts

The Centauri Carbon was very easy to unbox and set up, with next to nothing to do for assembly. Instructions in the manual were good, with the YouTube video really making them even clearer. It would have been better to have had them on the top layer of the box while unpacking.

The software was easy to set up, and we were up and printing in no time. We noted that the slicers’ estimated print times were almost always bang on – when the print job was left to run in Balanced mode, that is.

Initial calibration of the printer was a breeze, with a single click of a button to launch the various processes while we went about our business. Bed leveling was spot on, and there was no requirement to adjust the Z-gap for the duration of the review, although there was an easy setting to change it if needed.

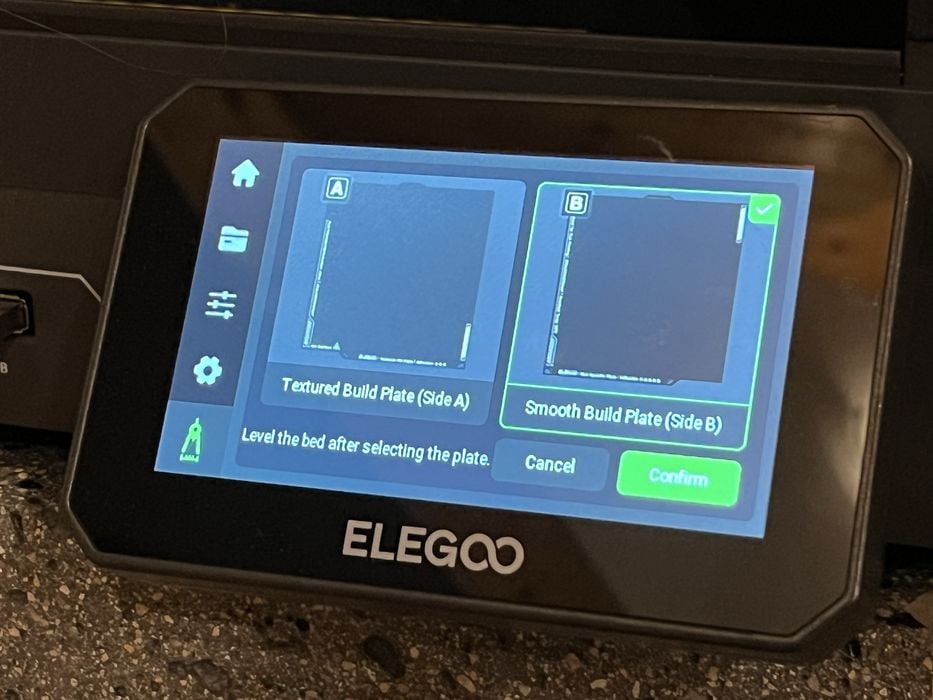

The multiple choice of build plate surfaces was nice, but we really found ourselves sticking with the multipurpose plate, as that is exactly what it was doing for us, sticking! Staying with the one build plate surface also saved us time from having to recalibrate the auto leveling that is required when flipping the plate.

ElegooSlicer’s upload and print option is great, and they offer a simple yet effective way to ensure that an operator cannot inadvertently start a print remotely while something is still on the bed. A job launched from the slicer will transfer but will not activate until the dialogue box from the previous print is cleared on the printer’s LCD screen.

We weren’t able to recreate the 15m #3DBenchy that Elegoo supplied, and we didn’t see the advertised speed of 500 mm/s in any of the slicer profiles, but the printer was still quite speedy nonetheless. Elegoo might consider releasing faster profiles after releasing the printer.

At one point in the review, the printer alerted us to a new version of firmware stating, “Going from 1.1.0 to 1.1.4. Fixed some issues with Elegoo slicer adaption.” Not surprising, as our review of the printer was happening prior to its official release, a few hiccups would be expected.

As for a few hiccups of our own, we noticed as we went through our test prints that the live camera feed in the Device tab of ElegooSlicer would drop out after only 5-10 seconds of streaming and that it would resume only briefly if we refreshed the screen.

After some testing, we determined the problem to be specific to the Mac version of ElegooSlicer and something that Elegoo should be able to remedy easily prior to product release. Our temporary fix during the review was to open the printer’s IP in any web browser window (except Safari, as it had the same issue) and view the live camera feed from the Device tab.

During the course of the review, we eventually became aware that prints were starting as soon as the extruder reached the correct temp, but before the build plate had reached its proper temp.

This only became apparent when we printed higher temp filaments like ABS. The build plate on the Centauri Carbon heats up very quickly, so lower bed temps of 60C for PLA were achievable (within a few degrees) during the time it took for the nozzle to heat up.

We found the problem to be simple, and the culprit was just the choice of an M140 command in the ElegooSlicer’s start GCODE. Simply put, an M140 command begins heating the bed but allows you to run other commands immediately afterwards, while an M190 command will wait until the bed temperature is reached before allowing any other commands to run. This is something Elegoo will surely remedy in the slicer prior to the printer’s release.

Filament changes were not only very easy with a single-click command on the LCD screen but were efficient too. Filament spools were easy to access and change on the side of the Elegoo Centauri Carbon, and the hotend assembly automatically clipped the filament for removal without the need to heat up.

Any new filament was extruded until the remainder of the previous was purged, discarding the filament “poop” out the chute in the rear of the Elegoo Centauri Carbon while wiping the nozzle on the silicone pad. There wasn’t an included STL for printing a “poop chute” to catch all the ejected bits of filament, but we found something useful online that we modified to work.

As for the performance of the printer in general – we really liked it! Elegoo has done a great job with the Centauri Carbon. It is a very solidly built machine that is quiet, accurate, and moves about competently and efficiently. It gave us some really great prints using the stock profiles in the slicer and did so quickly.

We look forward to seeing what Elegoo comes up with next.

One final point: an Elegoo representative told us:

“You will notice the price.”

As of today, Elegoo has not yet released the price point for the Centauri Carbon, but will do so in the next few days. It could be that the price is very attractive, but we’ll see what happens.

ELEGOO

CENTAURI CARBON PRINTER

★ BEGINNER 8/10

★ ENTHUSIAST 9/10

★ PRODUCTION 7/10

BEST FEATURES

✔︎ Quiet & reliable

✔︎ Easy loading

✔︎ Easy set up

QUESTIONS

✖︎ Camera feed

✖︎ Plate temperature

✖︎ Slow profiles

This is part three of a three-part series; please read parts one and two.

Via Elegoo