Our review of the Anycubic Kobra S1 Combo 3D printer continues with a look at Operations.

This is part two of a three-part series; please read parts one and two.

Anycubic Kobra S1 Combo Operations

The S1 has a very attractive and clear display during print operations, as you can see here. There are options for doing calibrations before printing, which is usually a good idea. You can also take a time-lapse video of the print, which is stored on the S1 for later retrieval.

Note that there is a “Dryer” switch. This turns on the heater in the ACE PRO to dehumidify your spools. It’s easy to do, but if so, be sure to slightly open the lid on the ACE PRO to allow the hot, moist air to escape. If you don’t, then the moisture just stays in the ACE PRO.

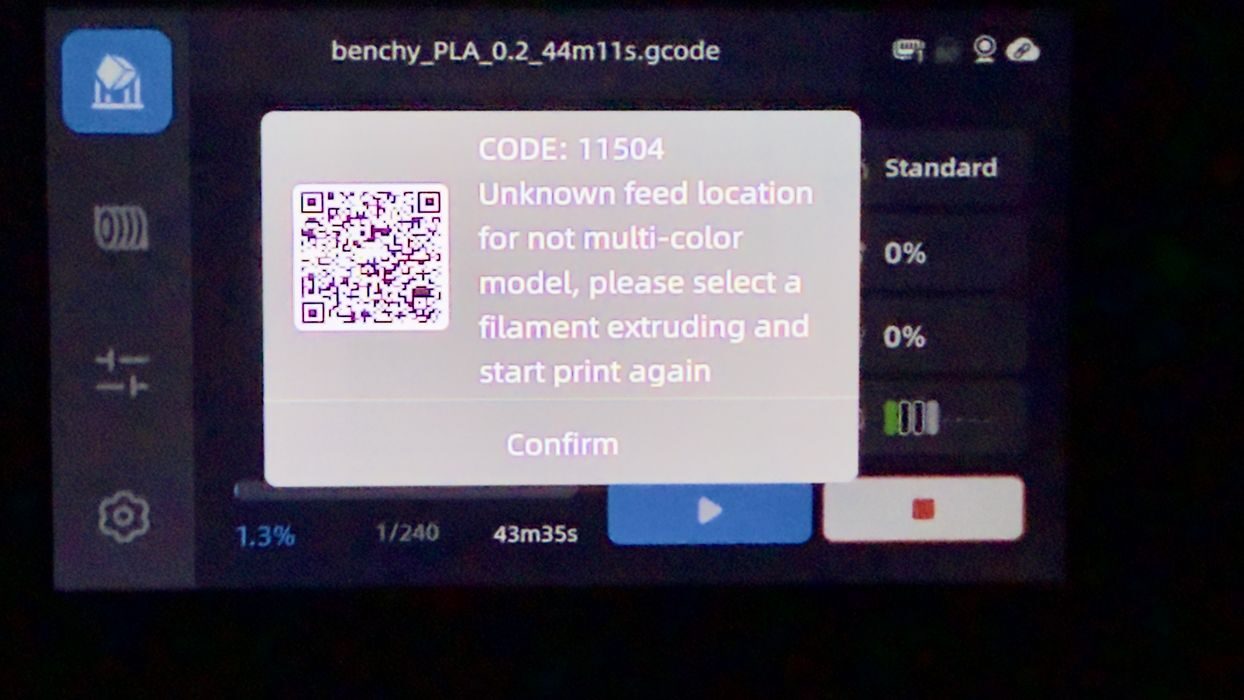

This is an example of one of many cryptic messages I received when using the S1. What exactly does this mean? If there’s one thing Anycubic should do, it’s to clean up all their messages to make them more understandable.

I guess I got things working, because my first poops were completed. These were not the last.

My first print was a canned job to print a #3DBenchy from the S1’s storage. The print seemed to start okay, but suddenly there were terrible scraping noises from the toolhead.

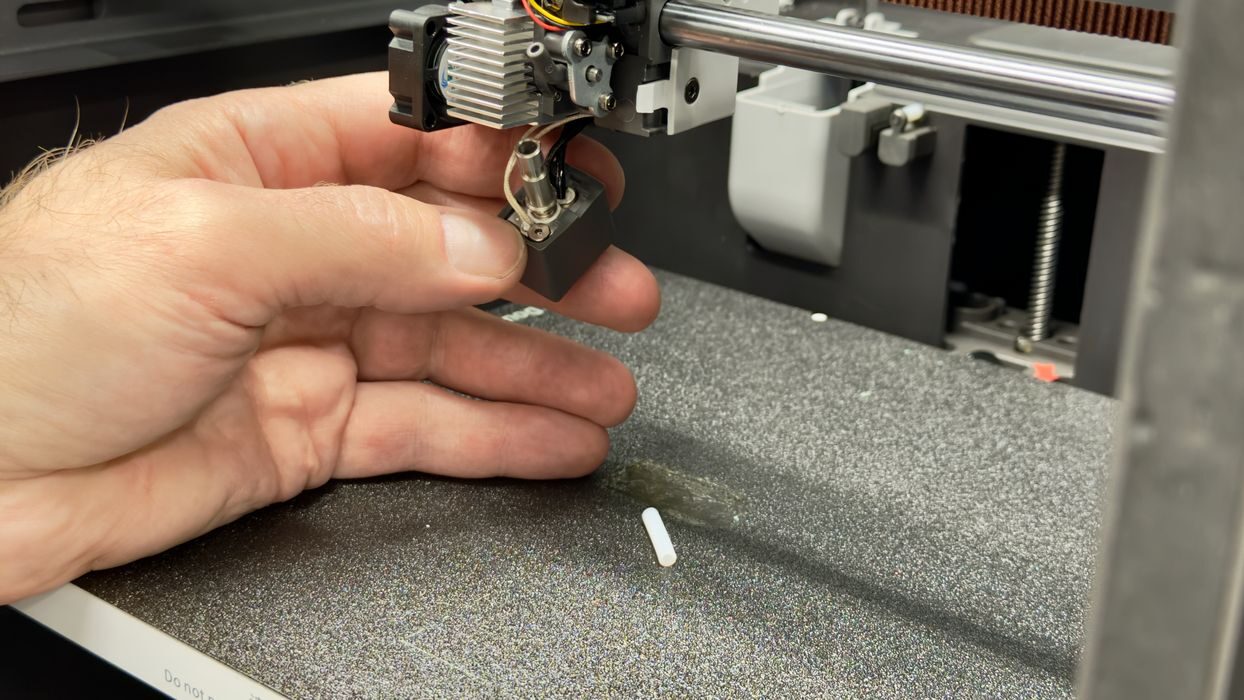

It seems that the nozzle was dragging on the print plate, and as you can see above, the coating was literally ripped right off. Something was wrong here.

The machine reported a clog, so it was time to take apart the toolhead to rectify matters. The cover on the toolhead quickly snaps off, and there’s a lever that supposedly releases the hot end. I had to take out the hot end to ensure the clog was cleared.

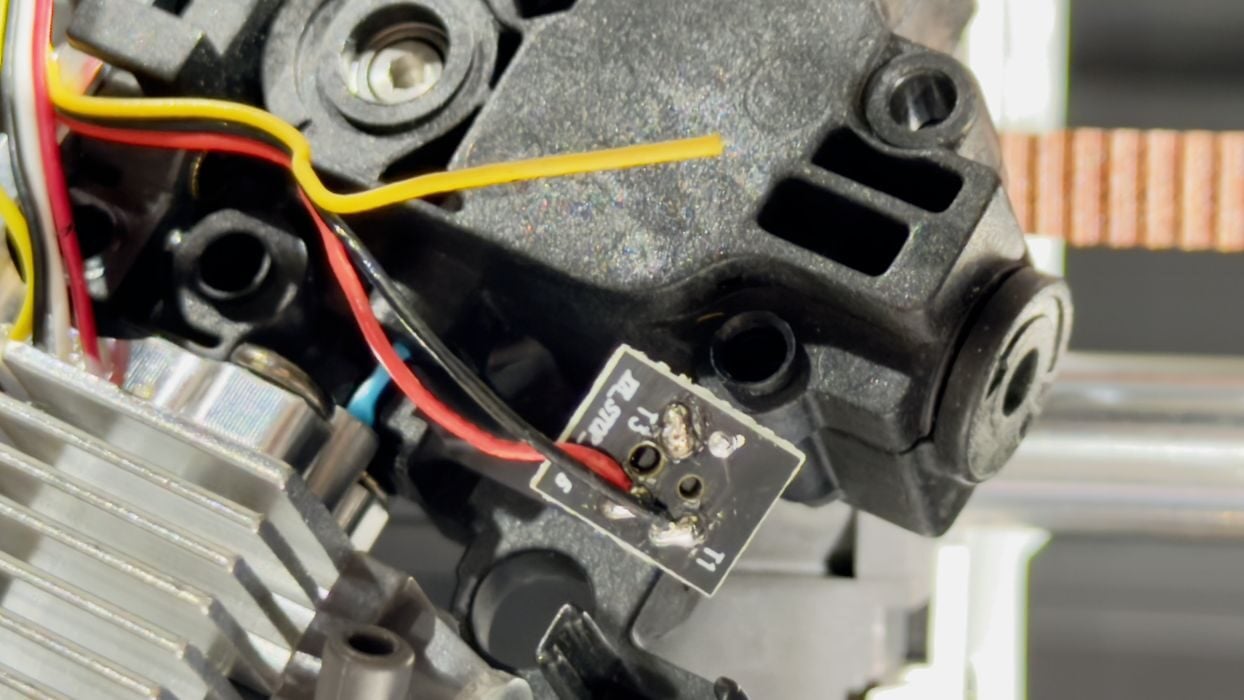

Unfortunately, a wire broke during the removal somehow. That’s not good.

After taking out the hot end, we realized why the toolhead was dragging. Inside the hot end, there is a short PTFE tube to guide filament downward. This tube should be pushed all the way in, flush with the top.

It was not. It turned out there was some debris at the bottom of the nozzle, preventing the PTFE tube from going all the way down. After we removed the debris, the PTFE tube could be positioned correctly, and the hot end reassembled. We did have to manually solder the broken wire back onto its board, however.

With all the parts back together, we recalibrated the machine and then tried a print. It did work, as we were able to print a 41m #3DBenchy. Unfortunately, the print quality of this print was pretty bad.

The reason for the poor quality was that the original nozzle wore down when dragging on the print plate during the initial problem. Here you can see the old nozzle on the left compared to a replacement sent to us by Anycubic on the right.

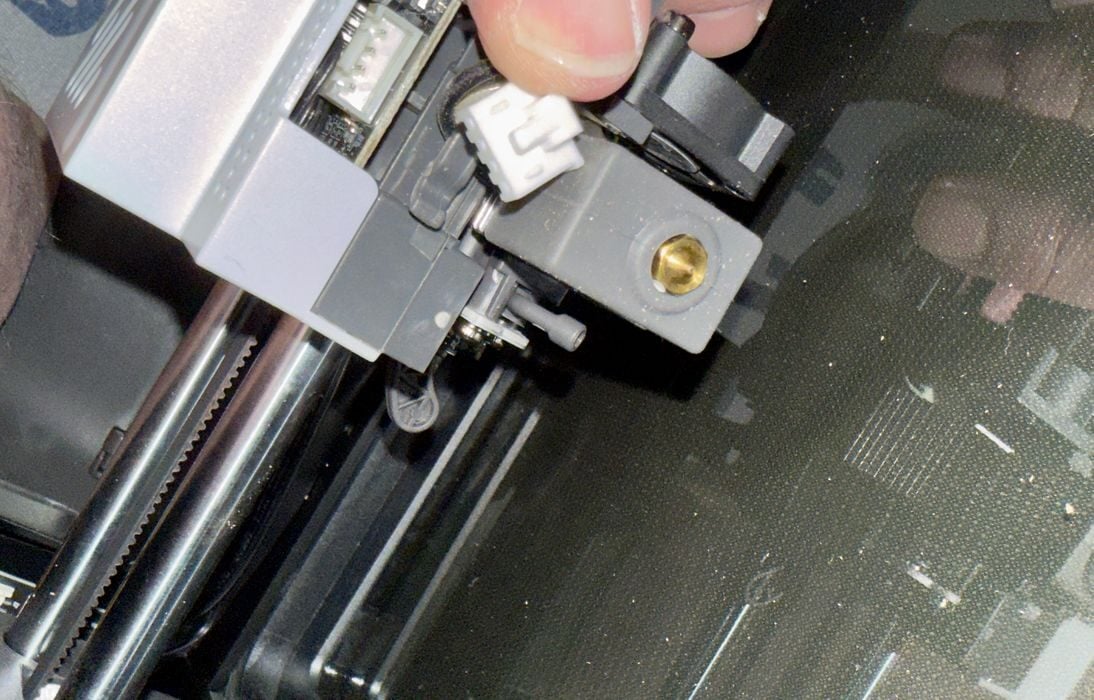

The S1 has quick-swap nozzles, in theory, but not in practice. We had to install the replacement nozzle, and it started well: you flip the lock lever on the toolhead, which releases the hot end. The hot end has a cable attached around the back, which you simply pull out.

The problem comes in when you are trying to plug in the hot end cable. It’s deep inside a crevice on the back of the machine in a dark chamber that you cannot reach around or see. It’s basically impossible to put this cable in easily. I ended up taking pictures, turning the machine on its side, using mirrors, etc. After an hour, I was finally able to get that damned cable plugged in.

The S1 does NOT have quick-swappable hot ends.

Finally, the S1 was back in action. We started printing many things.

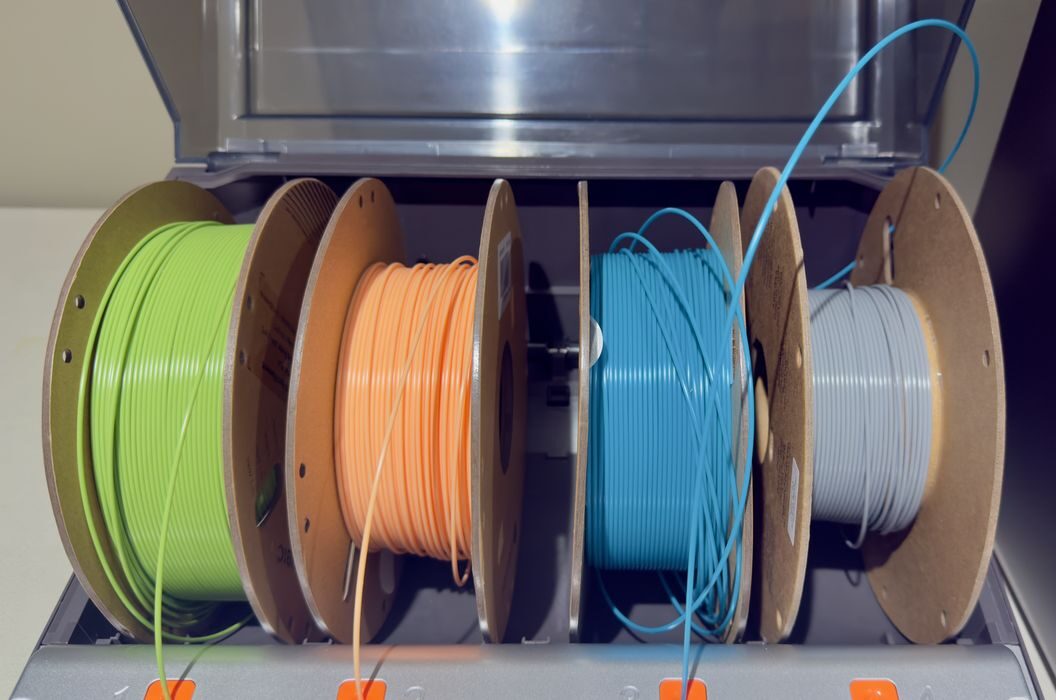

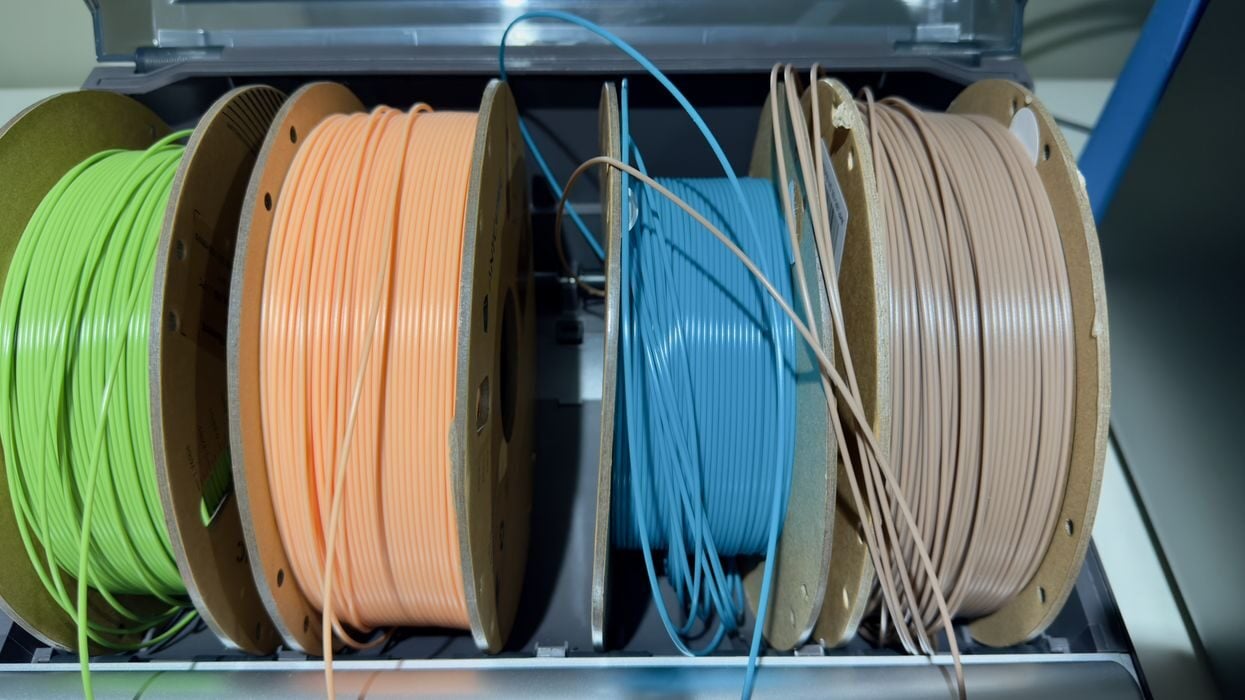

Except then something happened. The machine provided another cryptic message about filament, and it seemed that something was wrong with the ACE PRO. Opening up the ACE PRO, it appeared that somehow the filaments were backed up too much, generating a mess inside the unit. I had to take out the spill and rewind it manually to resume printing.

Then another tangle happened. It looked again like the filament feed was reversed, but somehow the filament slipped over the edge of the spool.

And another one happened. These are easy to fix if you are near the machine, but if not, your job would stop.

Then there was another problem with the filament feed, but it wasn’t a visible tangle. The filament would not move in any direction, even after powering off the ACE PRO.

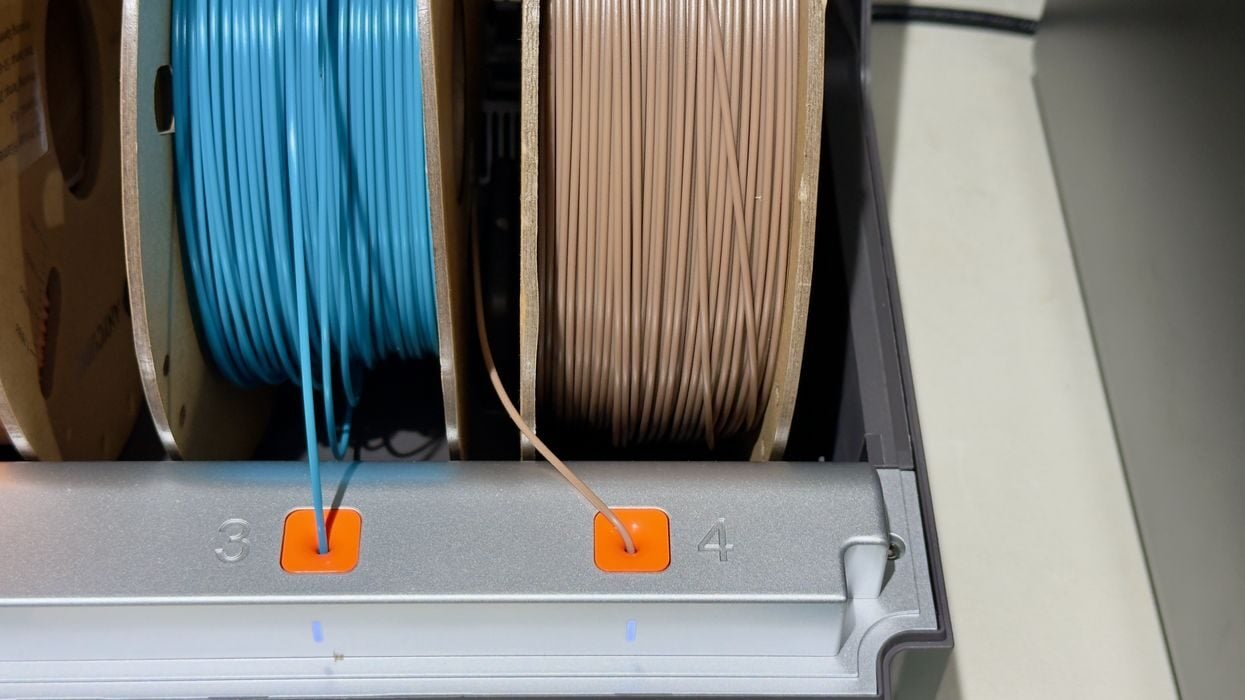

I used Anycubic’s Wiki to find out what to do, which was to disassemble the ACE PRO to find the stoppage. This requires you to open up a panel on the bottom and look inside the baffles.

Aha! This was the problem. Somehow the blue filament got looped around, creating a spiral that would obviously not fit through the PTFE tubes. I had to cut this filament out and reseed everything through to resume printing.

Operating the S1 was pretty straightforward, aside from the mysterious messages and ACE PRO tangles.

Via Anycubic