Our review of the Anycubic Kobra 3 Combo concludes with software, print results and final thoughts.

This is part three of a three part series, please read parts one and two.

Anycubic Kobra 3 Combo Software

Software on the Kobra 3 consists of the machine’s firmware, which we’ve discussed, as well as the custom-made AnycubicSlicer desktop software and Anycubic smartphone app.

AnycubicSlicer seems to be based on some version of PrusaSlicer, but there are some features changed, mostly in the interface. It works fine, and will be mostly familiar to operators. However, I did find the model painting feature deficient as described above.

AnycubicSlicer not only lets you prepare print jobs, but you can also directly dispatch them to the printer via WiFi. I found this extremely convenient, and I used it all the time.

I did find the slicer’s estimated print times were almost always way off, particularly for multicolor prints. In one case the slicer indicated the print job would take 80 minutes, but in reality the job took over eleven hours, eight times more than estimated. It seems that the estimating software does not account for the filament switching time.

Anycubic also provides a beta version of a new slicer based on Orca, which I found to be more functional, particularly model painting. However, this software doesn’t (yet) have the network connection to dispatch jobs to the printer. Because of this I would use the Orca version for multicolor models and the AnycubicSlicer for monocolor jobs.

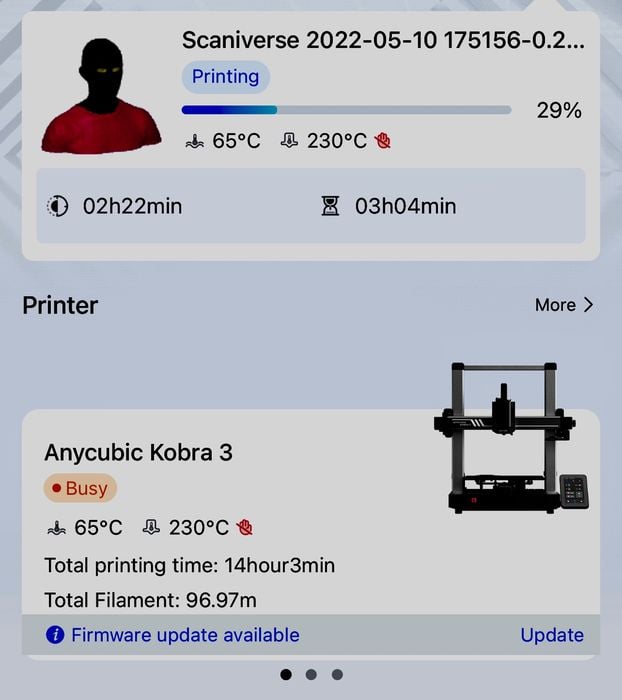

While printing it’s possible to monitor the progress of the job through the app. I found the display quite easy to read, although there were moments when the app didn’t sync or update the data correctly.

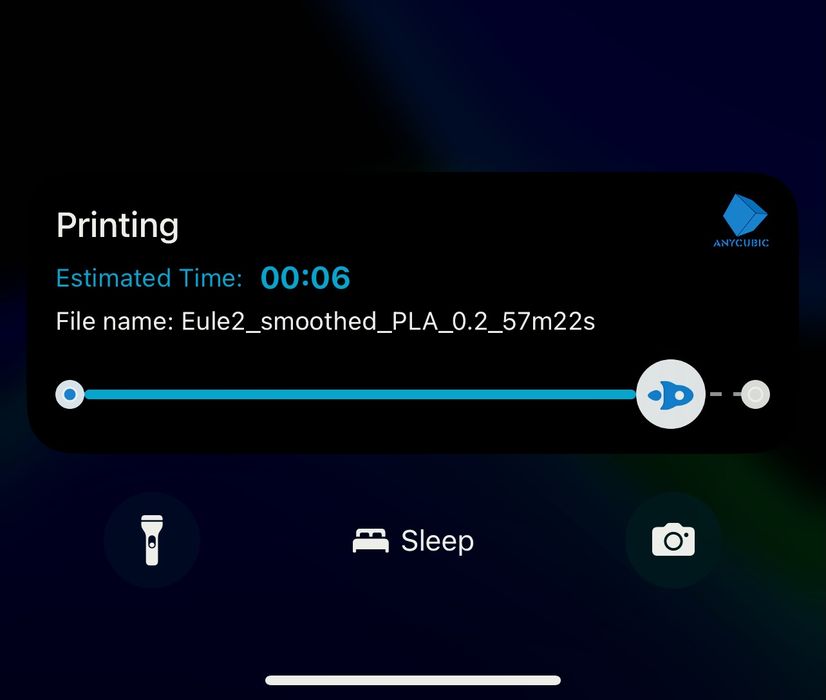

On my smartphone I noticed that the Anycubic app has a widget! It shows the print progress in this small window, which I found really useful. You simply pick up your phone and immediately see what’s going on.

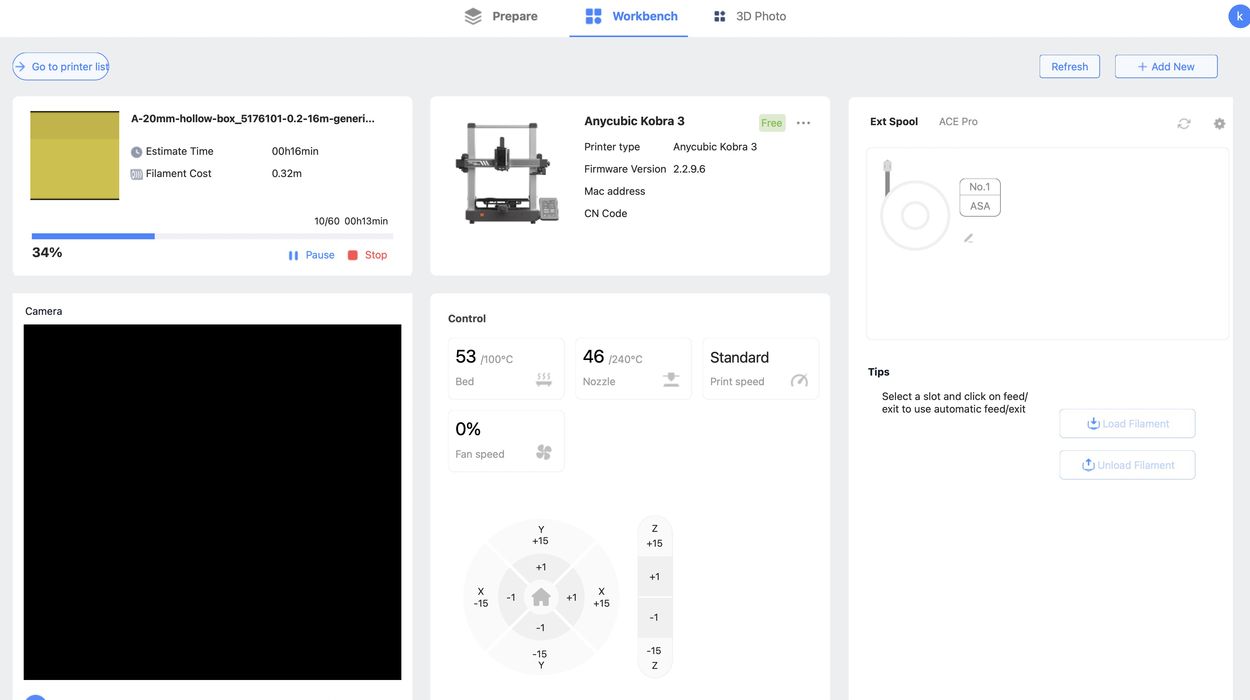

There were intermittent data coordination issues between the app, slicer and machine. Here we can see the slicer reporting the temperatures of the machine as 53C/46C, yet it’s in the middle of a print job where the temperatures are definitely not that low.

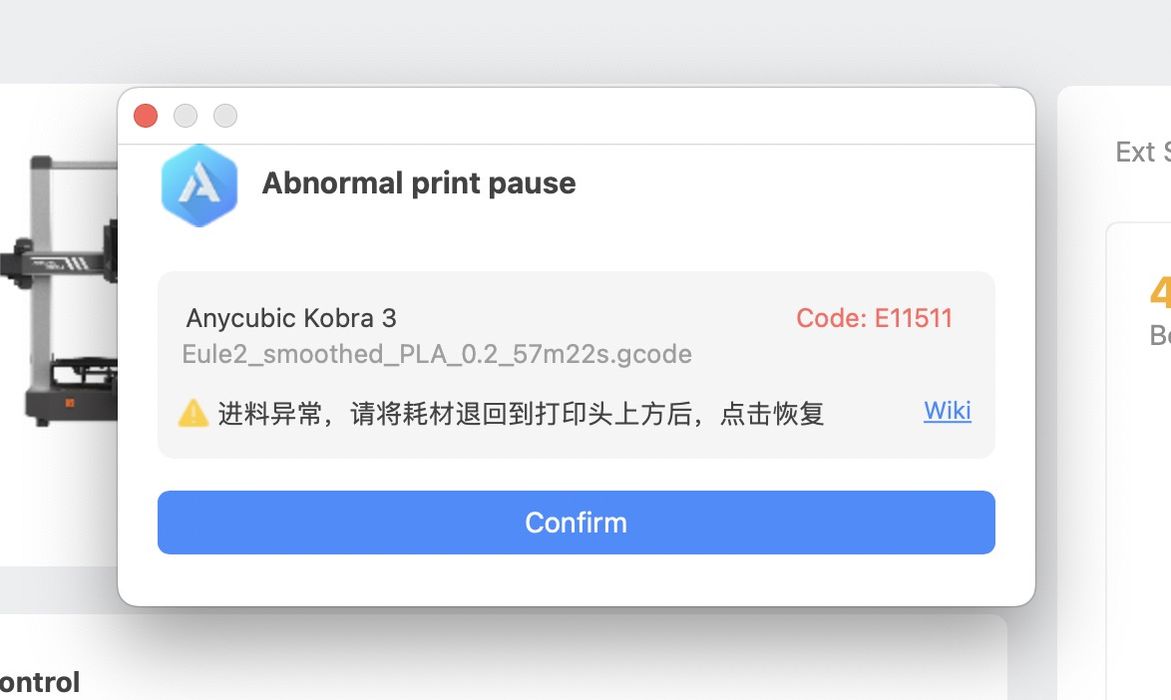

There were multiple instances of the software having language confusion. Here we can see a notice in the slicer written in Chinese, even though the interface is set to English. In this case, it’s saying that the filament is feeding abnormally, with advice on how to rectify the issue.

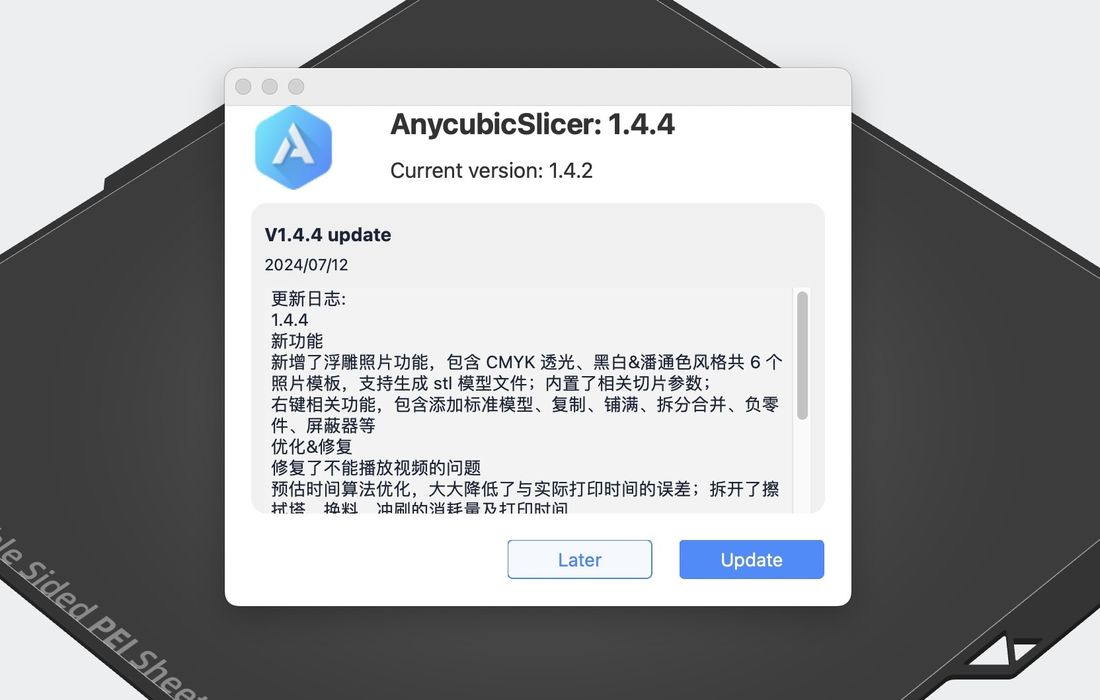

Here’s another one, where the slicer has a new version, apparently.

Finally, this was something I’ve never seen before: a firmware update notice (another one) appeared in the middle of a print job! The notice overlaid the job controls and I could not access them. I had to “cancel” the update and remember to do the update later. Firmware updates should never happen during a print job.

Anycubic has all the required software elements, but it seems there are a few bugs yet to work out.

Anycubic Kobra 3 Combo Print Results

In general the print quality from the Kobra 3 was pretty good, particularly on monocolor models.

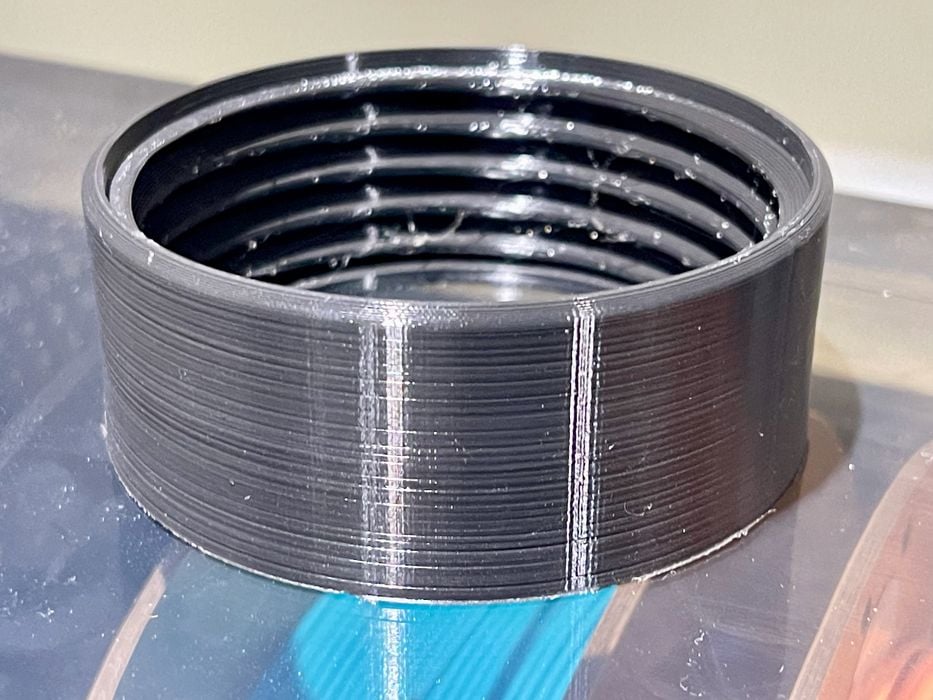

Here’s a multicolor owl, which completed after many hours, and produced a lot of waste as usual. Looking closely you can see some surface quality issues. I’m not quite sure what’s going on here, but it’s almost as if there is a Z-wobble because some of the layers are not perfectly aligned. However, I did not see this on monocolor jobs, so it must have something to do with filament switching. Does the X-axis really come back to the correct position after switching filament?

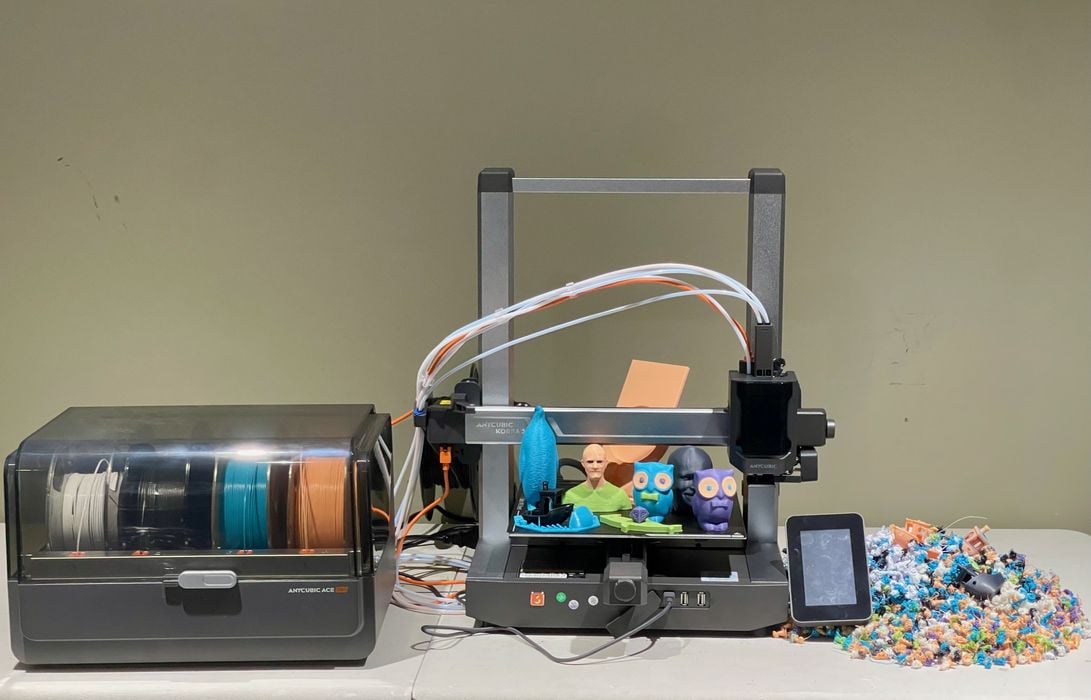

I printed these three multicolor owls and noticed similar quality issues on all of them. I can’t tell you how much filament was wasted to produce these critters, but it was the majority of the material.

After printing some multicolor objects I wanted to print some monocolor objects in non-PLA materials. For this I would use the external single spool mount instead of the ACE PRO. This would be how an operator would use the Kobra 3 if no ACE PRO was installed.

However, the Kobra 3 would repeatedly complain that the ACE PRO did not have the material I selected. I could not find a setting in the slicer to “turn off” the ACE PRO and force use of the external spool. I even unplugged the ACE PRO, and it still would not work.

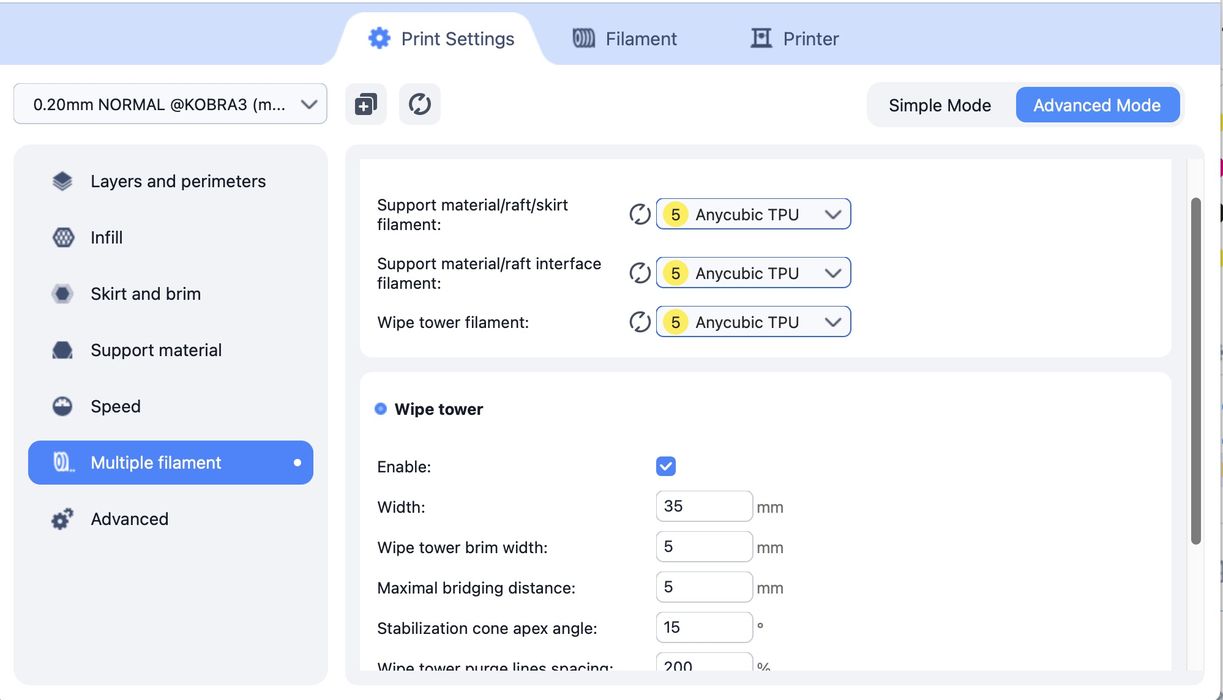

Eventually I realized I had to do this: In the settings I made the job “monocolor” by flipping each of these three materials to the same value. I wish there was an easier way to do this.

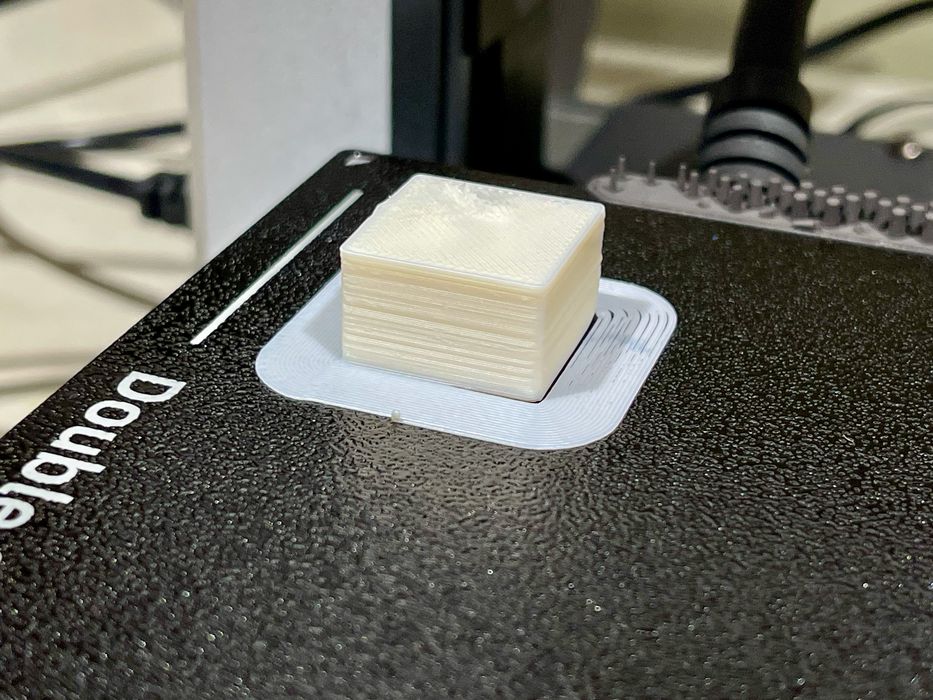

I tried printing a small test object in ASA (a material very much like ABS), and it worked, although I had to use a massive brim to counteract ASA’s tendency to warp.

I tried printing a large object with ASA, but it kept failing because the print would not stick to the bed, even after jamming the Z-gap as tight as I dared. It seems that ASA/ABS is hard to print on the Kobra 3, although it may be just an adhesion issue as I experienced with PLA.

I moved on to flexible TPU, a material notoriously difficult to print. To my surprise it worked perfectly on the Kobra 3! My guess is that the TPU sticks better to the print plate than the other materials, resulting in flawless prints. Perhaps the flexible TPU lands deeper into the texture of the plate, making for better adhesion?

I tried a larger TPU print and it also worked very well. I expect you might even be able to print TPU without a brim. The Kobra 3 is an excellent machine for printing TPU.

Anycubic Kobra 3 Combo Final Thoughts

The Kobra 3 Combo is the most advanced desktop FFF device yet released by Anycubic. It has a wealth of features, including the ability to 3D print objects in up to four colors (eight with a secondary ACE PRO attached).

The hardware seems very solid, with the exception of plate adhesion, which was a persistent issue throughout our testing. While TPU held down reasonably well, it was very difficult to get any other material to reliably stick to the plate. In one case an adhesion issue actually damaged our Kobra 3. Anycubic should work to resolve this issue as a priority.

The software pieces of the Kobra 3 puzzle seem pretty rough in places, and it’s clear that there are bugs and tweaks required. The good news is that this is software, and software can be updated. I’m expecting Anycubic to resolve all of the issues over time. In the meantime I fear that new users would be baffled by some of the confusing situations that result from the early-release software, along with instructions that doesn’t always match the hardware. When Anycubic resolves these issues, we would certainly consider giving the Kobra 3 Combo a higher rating.

Anycubic should adjust the print profiles. The profiles provided do work (adhesion issues aside), but they are not optimal: multicolor prints seem slower than they should be, and they waste a truly tremendous amount of material.

The Kobra 3 Combo is probably best used by enthusiasts who are able to overcome the software quirks and provide their own optimized print profiles. Beginners may find the Kobra 3 Combo quite confusing due to the multicolor complexity, instructions and software bugs, while professionals would find the Kobra 3 a bit slow and wasteful to effectively produce parts in any volume.

The Anycubic Kobra 3 Combo is a very promising machine, but it needs a few tweaks to tune it for ease of use and performance.

The Anycubic Kobra 3 Combo is now available for the very low price of US$449, and the Kobra 3 standalone is priced at only US$339.

ANYCUBIC

KOBRA 3 COMBO 3D PRINTER

★ BEGINNER 5/10

★ ENTHUSIAST 7/10

★ PRODUCTION 6/10

BEST FEATURES

✔︎ Multicolor printing

✔︎ ACE PRO features

✔︎ TPU printing

QUESTIONS

✖︎ Adhesion issues

✖︎ Software quirks

✖︎ Material waste

This is part three of a three part series, please read parts one and two.

Via Anycubic