We’re examining SUNLU’s resins and post processing equipment, beginning with assembly.

This is part one of a two part series, please read part two.

SUNLU Background

SUNLU is a Zhongshan, China-based operation that’s been producing 3D print materials and accessories for several years. Their materials are well-regarded and recently they’ve been expanding their product line with new products. One of them is the unique FC01 filament connector, which we recently reviewed.

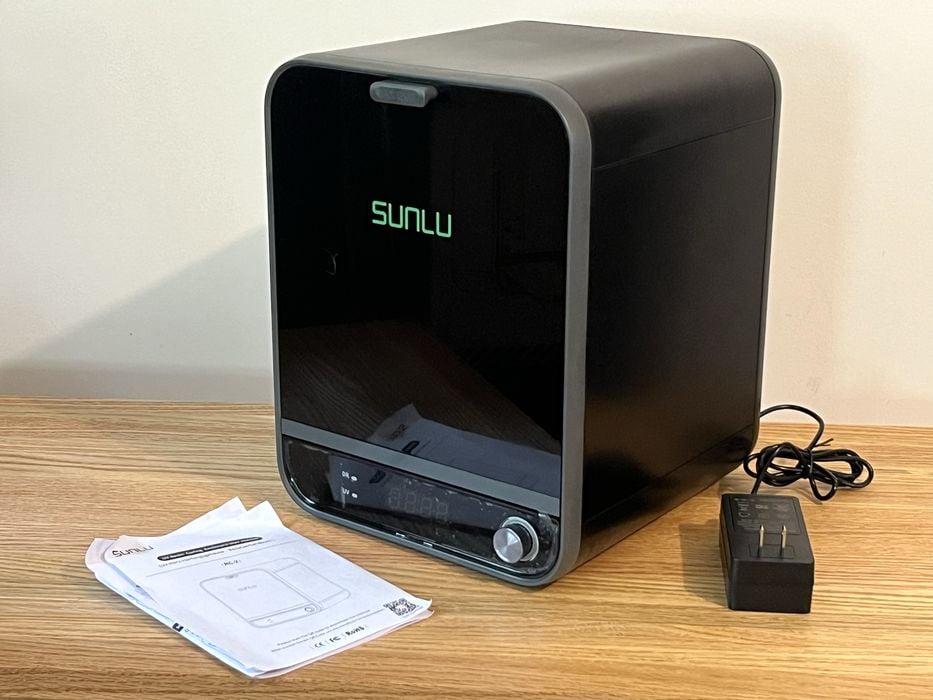

More recently SUNLU sent us new products for evaluation – a RC-2 UV Resin Curing Enclosure, SL UC01 Ultrasonic Cleaner and two jugs of their name-branded photopolymer resin.

Specifications and Features

The SL-UC01 Ultrasonic Cleaner has a footprint of 269 x 166 x 230 mm, a weight of 2kg and a solvent reservoir volume of 220 x 120 x 110 mm that can hold up to 2.7l of solvent.

It offers three levels of cleaning power at 30W/40W/60W, and comes with a small set of tweezers for moving items in and out of the tank.

The SL-UC01 is controlled with 4 buttons and a rotary knob – power on/off, switching between power modes, and increasing or decreasing operating time.

Mentioned but not included was “SUS304”, a photosensitive resin detergent that “can be used for 3D resin model cleaning, especially suitable for use on tiny models or models with more depressions.”

The RC-2 “Light curing oven” is SUNLU’s second generation device for hardening fresh resin 3D prints. It has a footprint of 245 x 235 x 305 mm, a maximum cure volume of 200 x 200 x 250 mm and a weight of 2.4kg.

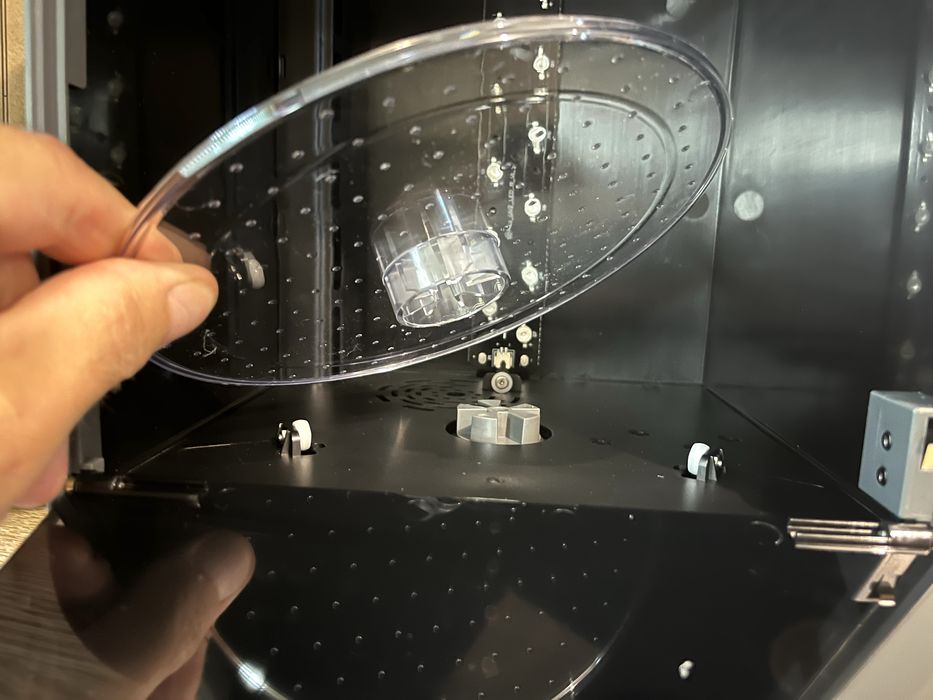

It features 360 degree curing via a removable turntable rotating under no less than 20 UV lamps – four at the top, four at the bottom and 12 on the sides, offering up a total of 42W of LED UV power. This is a 42% increase from SUNLU’s 1st generation model.

The roller support design of the RC-2’s turntable can accommodate a rather hefty maximum weight of 2kg. The UV light is combined with a fan based drying feature offering 3 adjustable air speeds that feed through SUNLU’s patented air duct technology, speeding up drying time by as much as 60%. Drying is an incredibly important aspect of resin post processing, so this is an interesting improvement.

The operator controls the RC-2 with a simple push button rotary knob that can toggle through various settings, which can be seen on the control panel.

SUNLU’s Standard Resin is curable with 385 – 405nm UV light and is suitable for use with most resin 3D printers (LCD/DLP/SLA/MSLA), and advertised as delivering efficient and reliable results, with low shrinkage, stable performance and low odor.

SUNLU have extensively tested and optimized the performance of their resins on multiple 3D printer models, ensuring exceptional compatibility and ease of use and cleans up easily with isopropyl alcohol or ethanol.

Their Standard Resin line offers an extensive range of colors, including solid, clear, and other options.

SUNLU’s water-wash resin is similar to the Standard Resin in most regards, with the exception that it can be cleaned with water instead of isopropyl alcohol.

Unboxing and Assembly

The RC-2 was packed well for shipping in a sturdy cardboard box with foam packing, as is usually the case for today’s equipment manufacturers.

Opening the box we found the device itself inside a separate protective poly bag, a power supply, rotating platform and user manual.

Assembly was very easy and just required the removal of protective films, insertion of the rotating platform, and attaching the power cable.

The RC–2 is capable of drying prints via an internal fan and curing them through the use of UV lamps, with a fully rotating turntable, assuring the model gets fully exposed to both functions.

The instructions mention an automatic mode, where the DR (dry) and UV (cure) indicators are both lit. This is a one-click function that automatically performs drying for 15 minutes (using three possible speed settings for the fan) followed by five minutes of UV curing, with the machine beeping upon completion.

This preset is mainly for models washed in isopropyl alcohol, as it is recommended that the dry time be more than 30 minutes if using water as a cleaning fluid.

The machine can also be operated in manual mode by accessing either the DR or UV functions independently by pressing the rotary knob and then adjusting the duration of each by turning the rotary knob.

For your eye protection, the unit will turn off if the front door is opened during UV operation. It will also go into standby mode if there is no operation within 20 minutes. SUNLU recommends cleaning the turntable regularly to ensure good light transmission, as there are several UV lamps located below the table. They also suggest leaving the door open during drying cycles to allow the moisture to more readily escape the enclosure.

The SL–UC01 was packaged very much like the RC-2, and again there was not much assembly required, with the exception of removing a small decal and plugging in the power supply. Also included was a small pair of plastic tweezers for picking up delicate parts.

The user manual mentions three power modes to choose from: 30W, 45W, 60W with a time setting range of 1 to 10 minutes and a buzzer indicating when the countdown is over. The machine goes into standby mode within 20 minutes of no operation.

The user manual and a sticker on the machine itself warn “after working continuous for 15 minutes, please shut down for five minutes before starting up“. This is likely to cool the machine.

The manual suggests four ways of cleaning: General Cleaning using warm tap water, Enhanced Cleaning by adding a few drops of detergent or non-corrosive cleaning solution (not included) , Partial Cleaning for large articles that will not submerge completely, and Deep Cleaning for extensive cleaning and disinfecting, adding warm water in a few drops of detergent or non-corrosive cleaner and cycling for two or three passes (not included).

The Photopolymer Resin was packaged well for shipping – sturdy leak proof container sealed inside a poly bag, placed inside a bubble wrap pouch and then a thin walled cardboard box. We noted that the external packaging gave no indication as to what type or color of resin was inside.

Opening the packages we found one jug of SUNLU Solid Grey Standard Resin, and one jug of SUNLU Water Washable Solid Grey Resin. Both packages included a few paint filters for transferring resin, with the water washable resin also including a small brush to aid in parts cleaning.

This is part one of a two part series, please read part two.

Via SUNLU