We’ve made a significant upgrade to our online 3D print job cost calculator.

The calculator allows 3D printer operators to compute reasonable prices for customer jobs based on your cost to produce the parts and a profit markup.

Pricing for jobs is a frequent question in online 3D printer forums, so we built a system to include all aspects of performing the printing for customers.

Often new makers might multiply the cost of job materials by five, or other simple approaches. But these might overestimate the job, resulting in loss of the customer to lower priced alternative services. Or the price might be too low and you’d be losing money.

Simple approaches don’t always work because they sometimes don’t directly account for labor, cost of the printer, intermittent failures, and other factors, all of which contribute to the long term cost of operations.

The Fabbaloo Print Job Cost Calculator takes all factors into account and presents a true costing of the work, along with markup for profit. The calculator walks you through the factors required, which are usually pretty easy to enter.

The latest calculator version includes a number of new features:

- Addition of “design cost” to account for the cost of acquiring or creating the 3D model being printed.

- Addition of “component cost” to account for any nuts, bolts, wiring, or other non-printable items that are included with the prints.

- New and improved visual appearance that should be easier to use.

- Clearer cost breakdown upon calculation

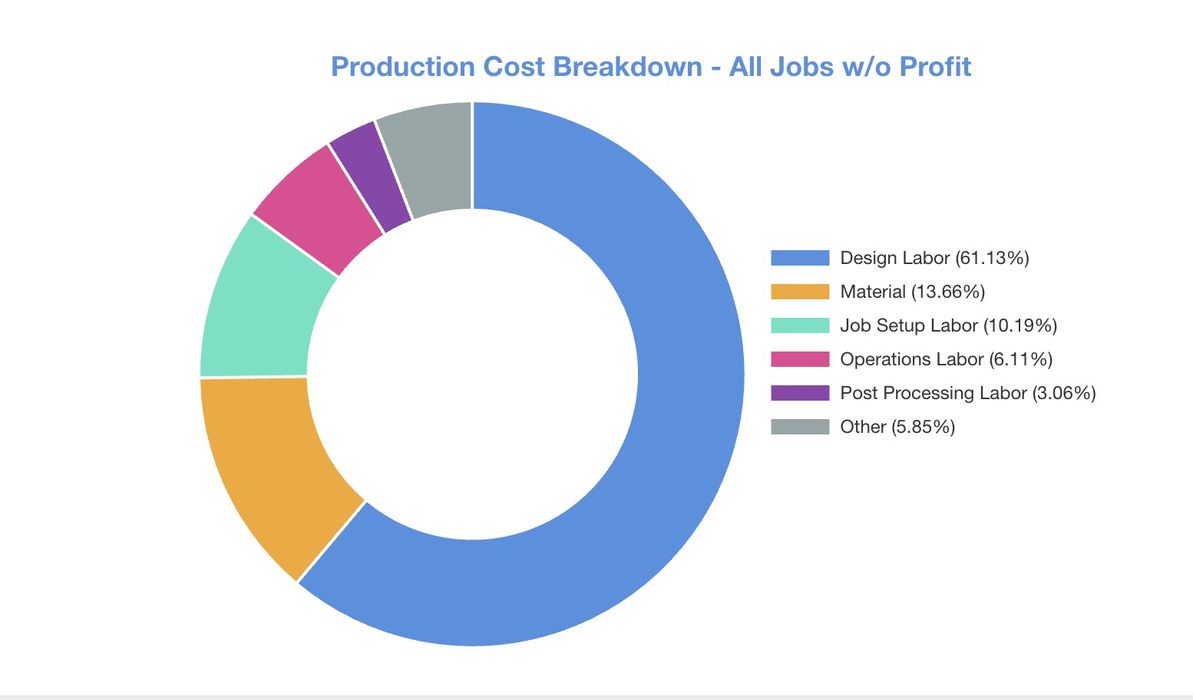

- Pie chart showing the top six categories of cost to produce the jobs.

- Floating window showing the total customer price for the jobs.

We have to credit Fabbaloo, reader Dave McCready for the idea to include component cost. McCready’s business, Angler’s Choice, produces a wide range of accessories for fishing, including the keychains shown at top. Note they include a ring and snap hook, which McCready wanted to include in his price to the customer.

We thought this was a great idea and added it to the calculator.

When using the calculator, you’ll immediately notice that the major cost of producing parts is definitely not the machine, electricity or materials. The majority of the costs are your time and in some cases, the design cost. This is why post processing has become a hot topic: it’s a costly step in producing parts.

We’re open for suggestions to modify the calculator.

Enjoy! Try the calculator here.