Charles R. Goulding and Preeti Sulibhavi examine how Hasbro’s new CFO, Gina Goetter, is spearheading a cost-saving initiative, exploring 3D printing to enhance product design and reduce production expenses.

Hasbro’s new CFO, Gina Goetter, has announced that the company is analyzing 40 cost-saving ideas for its Nerf toy product line. Although complete details of the ideas were not disclosed, they do include product design elements like plastic thickness. We have always been interested in toy plastic design concepts since our first client to use 3D printers was one of the major toy companies for plastic prototype designs almost 20 years ago. Eight of the 40 ideas have the potential for US$8 million in savings.

3D printing generative design can not only reduce costs but also provide improved product functionality and quality.

Nerf toys are only one of Hasbro’s multiple major products. Presumably, if the Nerf initiative provides the anticipated results, other product lines will undergo the same process.

The Nerf process also involves packaging process analysis and cost benchmarking which CFOs can use some public company reporting documents to compare.

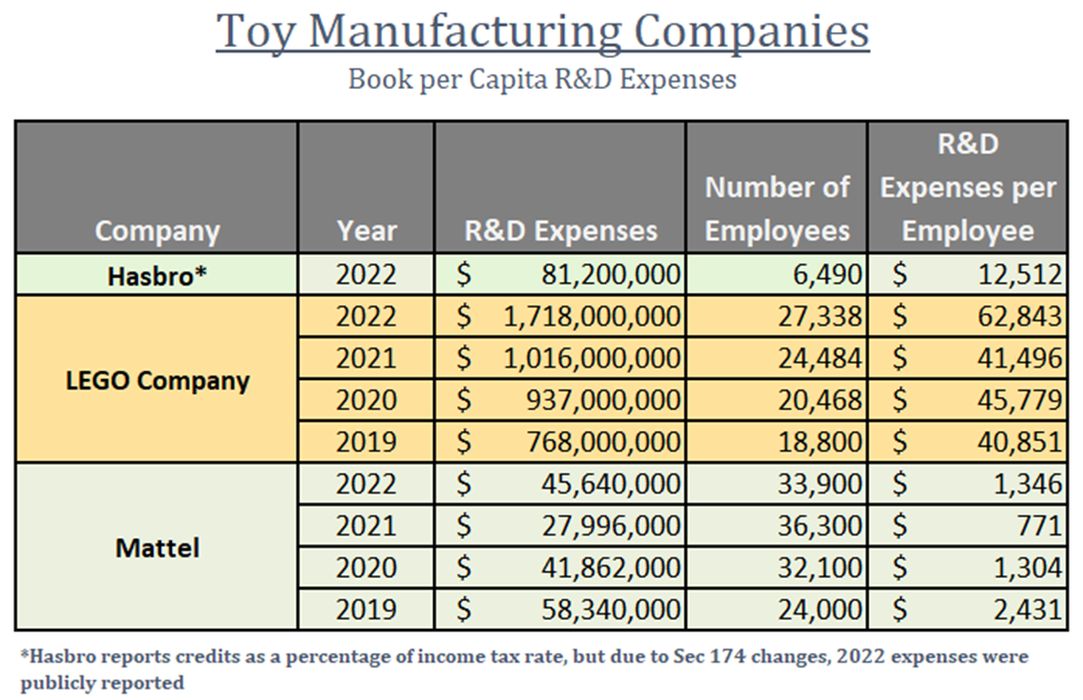

Hasbro reported US$5.43 billion in net revenues for 2022. As of December 31, 2022, Hasbro had approximately 6,500 employees globally. Prior to joining Hasbro in 2022, Gina Goetter served as CFO of Harley Davidson. Harley-Davidson has utilized 3D printing for various applications including concept modeling and functional prototyping of motorcycle parts and components.

3D printing, or additive manufacturing, allows for highly customizable and complex designs without the constraints of traditional manufacturing methods. For toy companies like Hasbro, 3D printing enables rapid prototyping, accelerating the design process. It also facilitates mass customization and on-demand production of toys tailored to individual customers.

Recent examples of Hasbro leveraging 3D printing include creating customized figurines and accessories for popular brands like Transformers, My Little Pony, Dungeons & Dragons and Magic: The Gathering. Hasbro uses 3D scanning and printing to produce one-of-a-kind figurines, jewelry and props based on customers’ designs. This allows fans to bring their own characters and creations to life.

Hasbro also utilizes 3D printing technology in-house to iterate and refine toy designs more rapidly. The ability to quickly 3D print multiple variations of a toy during the prototyping phase results in faster time-to-market once the final design is approved for production. Streamlining prototyping with 3D printing additionally lowers costs associated with traditional methods like CNC machining or injection molding hard tooling.

As Hasbro focuses on new cost savings around production and packaging for Nerf, expanded adoption of 3D printing could generate further efficiencies. Generative design software powered by artificial intelligence can now optimize 3D printable designs to meet specified goals and constraints. This emerging application of 3D printing presents intriguing possibilities for toys. Designers could input parameters like cost targets, safety requirements or desired functionality into generative design software. The software would then algorithmically generate optimized toy design concepts balancing those inputs. Human designers subsequently select and refine the most promising options.

The Research & Development Tax Credit

The now permanent Research & Development Tax Credit (R&D) Tax Credit is available for companies developing new or improved products, processes and/ or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits

Conclusion

It will be interesting to follow Hasbro’s cost reduction program for Nerf toys. Our view is that 3D printing has a role to play in this process, whether through rapid prototyping or future applications of generative design. As a leader in the toy industry, Hasbro’s initiatives could influence wider adoption of additive manufacturing.

If the Nerf program successfully cuts costs via methods like 3D printing, deployment across other Hasbro brands would logically follow. We anticipate ongoing innovation in using additive manufacturing technologies throughout the design, prototyping and production stages for toys. Efficiencies unlocked could enable toy companies to meet consumer demand for mass customization profitably.