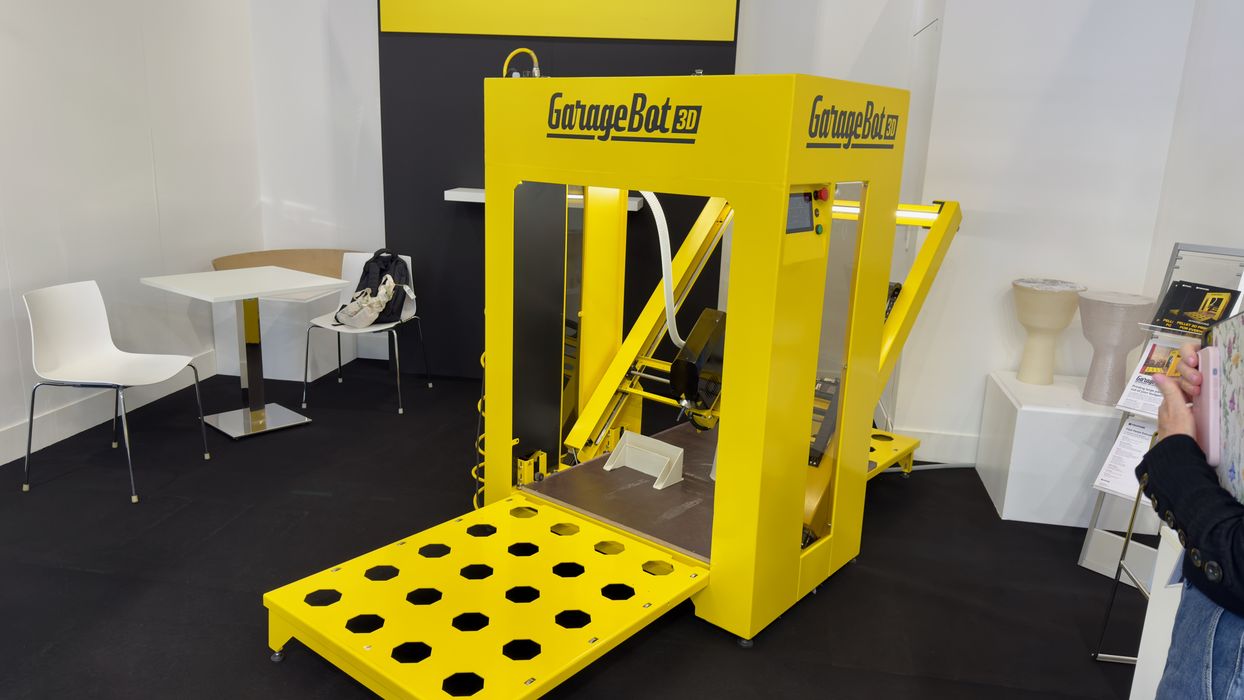

I saw the most unusual 3D printer at Formnext, the GarageBot3D.

The GarageBot3D is produced by startup company Profabb, based in Riga, Latvia. They’ve taken three years to develop this machine, and now it’s presented to the public.

As you can see from the images, the GarageBot3D is not your standard 3D printer.

One of the most unusual features is that it is foldable: both sides can tip upwards, making the machine quite small for storage. It also fits through standard doorways. It weighs 250kg, but has wheels to be easily moved around. The idea is that it’s designed literally for a garage: keep it folded up until you need to print something.

Not only do the sides fold up, but the toolhead itself can be tilted. It can operate in “normal mode” by printing objects in place. However, when the toolhead is tilted to 45 degrees, the GarageBot3D is transformed into a kind of belt 3D printer.

Except there’s no belt.

Instead of a belt, the print surface is literally just a piece of plywood. Large gears along the sides grab the sheet and push it forwards and backwards to effect Y-axis motion. The basic build volume is 800 x 2000 x 1000 mm.

This means that the GarageBot3D can not only print larger objects with its huge build volume, but also it can print extremely long objects when operating at 45 degrees. They say you can print up to 5 m objects, or 150kg of material.

How can a lengthy object be printed without a belt? The solution is brilliant: just put in another sheet of plywood (or plastic) and it pushes out the first sheet. Repeat as necessary.

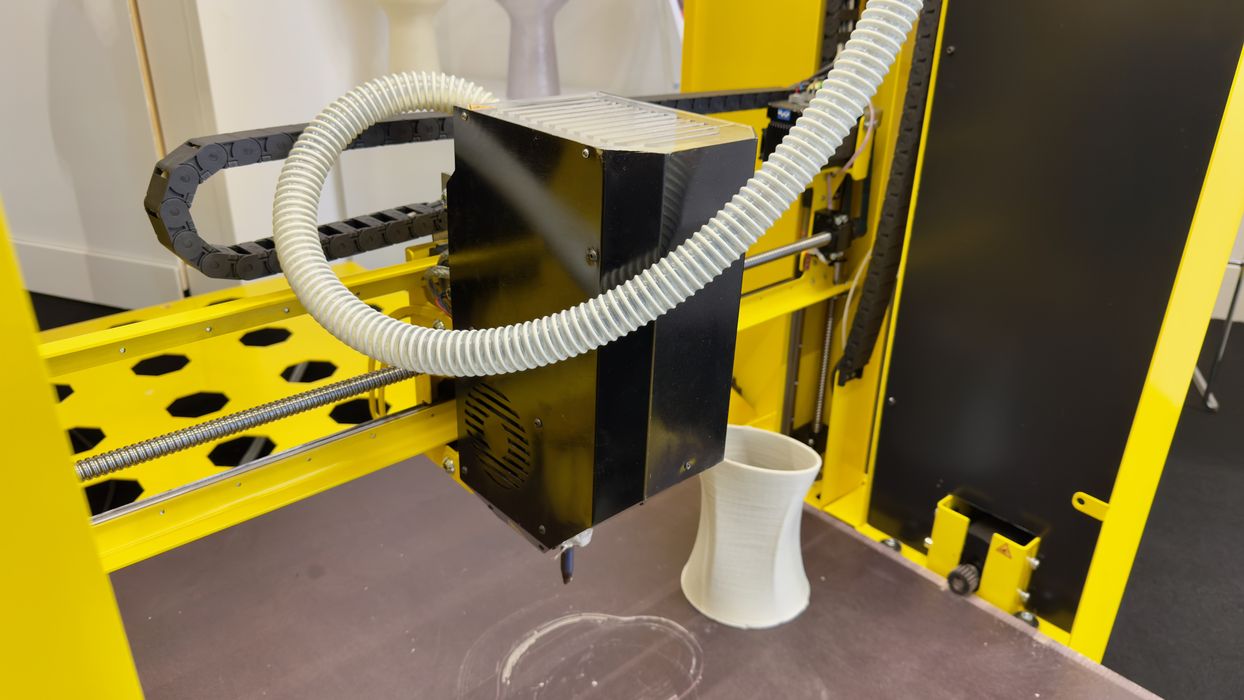

About the material: the GarageBot3D uses PLA pellets, not filament. This makes operating the machine vastly less expensive than other filament devices. There is a filament toolhead available, but I don’t see why you’d use it on this machine.

The nozzle diameter is larger, as you’d expect for a machine printing huge objects. Two nozzles are provided, 3mm and 5mm, both much larger than the standard 0.4mm nozzles on desktop devices.

The key benefit of the GarageBot3D is cost ownership. It can be used to print furniture-sized objects, which is normally done by very expensive robotic arm systems. Here there are no robot arms, and the machine is therefore much, much cheaper. At a price of €24,000 (US$25,000), it is 10X less expensive than some robotic systems that do much the same thing.

The price of the machine, combined with the use of inexpensive pellet material, means that many more buyers can take advantage of this machine.

Finally, Profabb told us they are very interested in finding dealers and resellers for their new machine both in Europe and the rest of the world.

Via Profabb