Charles R. Goulding and Preeti Sulibhavi examine Bell’s use of 3D printing to propel the U.S. Army’s next-gen tiltrotor capabilities.

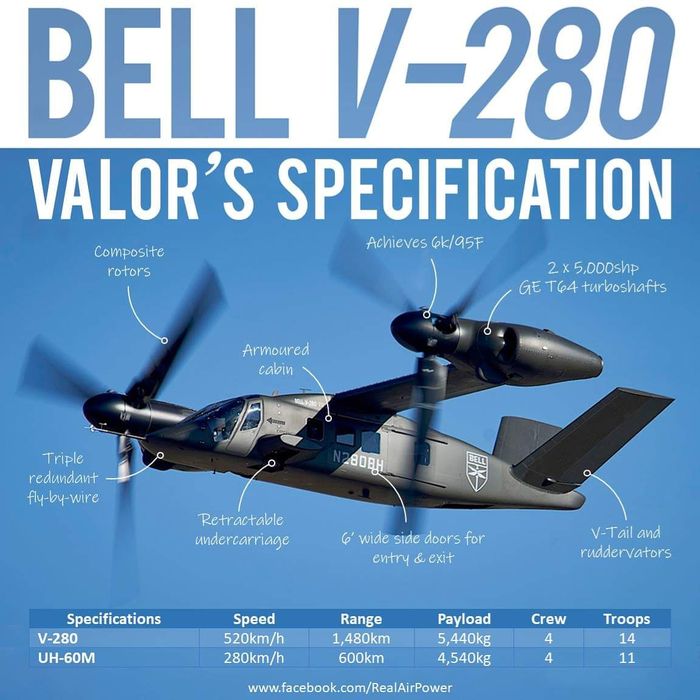

Bell Textron’s potential US$70 billion contract with the U.S. Army centers on producing the V-280 Valor, a tiltrotor aircraft that could replace the UH-60 Blackhawk. This significant contract arises from the Army’s Future Long-Range Assault Aircraft (FLRAA) initiative, which aims to modernize aviation capabilities by 2030. The contract begins with an initial US $7.1 billion phase to deliver prototypes and low-rate production units, with additional phases and options that may increase the contract’s overall value to US$70 billion over the aircraft’s lifecycle, contingent on meeting production and delivery targets as well as potential sales to other militaries globally. Bell’s V-280 Valor triumphed over a competing design from Sikorsky-Boeing, largely because of its advanced tiltrotor technology, which offers increased speed, range, and operational flexibility—key attributes for evolving military needs.

In recent years, Bell has adopted additive manufacturing, also known as 3D printing, to enhance its production processes. Here are four examples where Bell has leveraged 3D printing and additive manufacturing in its production, manufacturing, prototyping, and maintenance processes:

Prototyping and Rapid Development

Bell employs 3D printing in prototyping, allowing for swift design iterations and cost-effective testing before entering mass production. For the V-280 Valor, Bell has used additive manufacturing to prototype complex parts, particularly for aerodynamics testing, which is crucial for optimizing the Valor’s tiltrotor capabilities. This approach has enabled Bell to speed up the development cycle and conduct multiple testing phases with ease, facilitating rapid redesigns without the need for costly traditional manufacturing methods.

Tooling and Part Production

Bell uses 3D printing to create custom tooling for assembling aircraft components, including the V-280 Valor’s fuselage. By printing specialized tools in-house, Bell not only reduces lead times but also increases customization for specific aircrafts requirements. This technology has also allowed the company to produce lighter, ergonomic tools tailored to the assembly process, further streamlining operations. Additionally, Bell has been able to utilize 3D printing to produce durable and intricate parts that would be challenging to make with conventional methods.

Manufacturing High-Performance Components

Additive manufacturing has given Bell the flexibility to produce high-performance components for its tiltrotor aircraft, enhancing strength and reducing weight—an important factor for both performance and fuel efficiency. For example, Bell prints select components out of titanium and other lightweight materials, optimizing the aircraft’s weight distribution and contributing to its high range and speed. Parts produced through 3D printing can also be more resilient and finely tuned to the Valor’s design, supporting its intended versatility in both long-range and high-speed missions.

Maintenance and Repair Solutions

Bell also utilizes 3D printing in maintenance operations to support field repairs for aircraft parts. By providing digital designs for critical components, field technicians can quickly produce parts on-site, which is especially useful in combat or remote environments where supply chain access may be limited. For instance, technicians could print temporary replacement parts or jigs to expedite repairs, maintaining mission readiness. This innovation in field maintenance contributes to the Army’s operational efficiency, reducing aircraft downtime and streamlining logistical support.

Below is a table that depicts Bell Textron’s research and development expenditures over the past few years.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

These applications underscore Bell’s strategic use of additive manufacturing to stay competitive, reduce costs, and deliver advanced aviation solutions. As the FLRAA project unfolds, Bell’s integration of 3D printing will likely expand further, supporting a future where aircraft components are produced faster, lighter, and tailored to evolving combat needs.