Charles R. Goulding and Peter Saenz explore how ATI’s strategic focus on metallurgy and additive manufacturing positions it at the forefront of nuclear energy revival, defense innovation, and sustainable supply chain solutions.

Allegheny Technologies Incorporated (ATI) is a publicly traded company headquartered in Pittsburgh with a long history of supplying high-performance alloys and titanium products to some of the world’s most demanding industries. In 2024, ATI’s sales are expected to be around US$4.2 billion, supported by 7,800 employees. While ATI has stated that its strategic focus is on advanced metallurgy, its longstanding expertise in high-performance alloys and recent investments suggest that it is well-positioned to leverage additive manufacturing (3D printing) as a core capability. By refining its material science expertise and divesting certain non-core operations, ATI is strengthening its ability to support industries requiring on-demand production, resilient supply chains, and sustainable manufacturing.

ATI’s Evolution and Strategic Direction

In November 2024, ATI sold its precision rolled strip operations to Ulbrich—a move designed to concentrate on areas where the company can have the greatest impact. This decision is backed by a multi-year, US$700 million share repurchase program, reflecting ATI’s confidence in its strategic realignment and financial position. These changes highlight the company’s return to its core capabilities in advanced metallurgy.

Although not explicitly stated in ATI’s press releases, the realignment suggests a plan to dedicate more resources toward additive manufacturing. ATI has been expanding its 3D printing capabilities through:

- Acquisition of Addaero: A specialized Aerospace & Defense additive manufacturing firm.

- Establishment of a Dedicated AM Facility: Located near Fort Lauderdale, Florida, to support parts production for the U.S. Naval Nuclear Propulsion Program.

- Collaboration with GE Aviation: Developing melt-less titanium alloy powder for advanced 3D printing applications.

The Rise of 3D Printing in a Changing World

Additive manufacturing has evolved from a niche prototyping tool into a key driver of industrial transformation. In an era of geopolitical tensions and supply chain disruptions, 3D printing offers localized, on-demand alternatives that reduce dependence on external suppliers. For instance, in defense scenarios, Australian-developed 3D metal printing has already been deployed in war zones to replace damaged vehicle parts rapidly—highlighting how crucial it is to expedite production in high-pressure settings.

Beyond speed and flexibility, 3D printing aligns with the push for sustainability. Traditional manufacturing methods often waste large amounts of raw material, whereas additive processes can drastically minimize excess. ATI’s expertise in specialty alloys enables the production of stronger, lighter parts while conserving resources, helping to lower the overall environmental impact.

A New Opportunity for 3D Printing: Nuclear Energy Revival

A significant policy shift under the new Trump Administration has propelled nuclear energy back into the spotlight. As artificial intelligence (AI) accelerates the growth of data centers that demand high-output power, nuclear energy is being reconsidered as a critical component of the nation’s energy mix. However, reviving dormant nuclear plants is a complex undertaking. Many reactors were constructed decades ago, and the specialized components required for maintenance and upgrades are often no longer manufactured. Compounding this issue is the aging skilled workforce—many of the machinists and engineers with expertise in fabricating reactor components are retiring, and fewer younger workers are entering these fields. This decline in specialized knowledge makes it even more difficult to restore nuclear infrastructure through traditional manufacturing methods.

New tariffs and geopolitical tensions further complicate importing such parts, increasing costs and, in some cases, making it nearly impossible to acquire necessary components from foreign suppliers. With a shrinking domestic workforce and growing trade restrictions, the nuclear industry must explore alternative manufacturing solutions to meet demand.

3D Printing as a Solution to Nuclear Industry Challenges

One of the most promising ways to address supply chain constraints in the nuclear sector is through additive manufacturing. Rather than waiting months or even years for specialized parts to be traditionally machined or imported, nuclear operators can collaborate with companies like ATI to 3D print complex, obsolete components on demand. This approach not only shortens lead times but also revitalizes domestic manufacturing capabilities critical to national security and energy independence.

ATI has already demonstrated its ability to extend the life of legacy systems by combining its aerospace-critical materials science expertise with additive manufacturing to facilitate rapid design iterations and low-volume production of 3D printed titanium parts for mission-critical helicopter programs, such as the Sikorsky VH-3D Sea King—used as the U.S. President’s helicopter since 1961. A similar strategy could be employed to develop or improve parts for legacy nuclear facilities.

Challenges and the Road Ahead

While 3D printing presents an innovative path forward, several barriers must still be addressed. First, nuclear components must meet strict safety and quality standards before they can be used in reactors. The Nuclear Regulatory Commission (NRC) will need to evaluate and certify any 3D printed parts—a process that can be lengthy and costly.

Second, although 3D printing works well for small-batch production, producing large-scale reactor components remains challenging. Continued investment in large-format printers and advanced materials research will be necessary to scale up effectively.

Finally, cost considerations also come into play. Additive manufacturing can be more expensive than traditional methods for larger parts. However, the ability to produce low-volume, high-complexity components makes it an invaluable tool for addressing supply chain shortages.

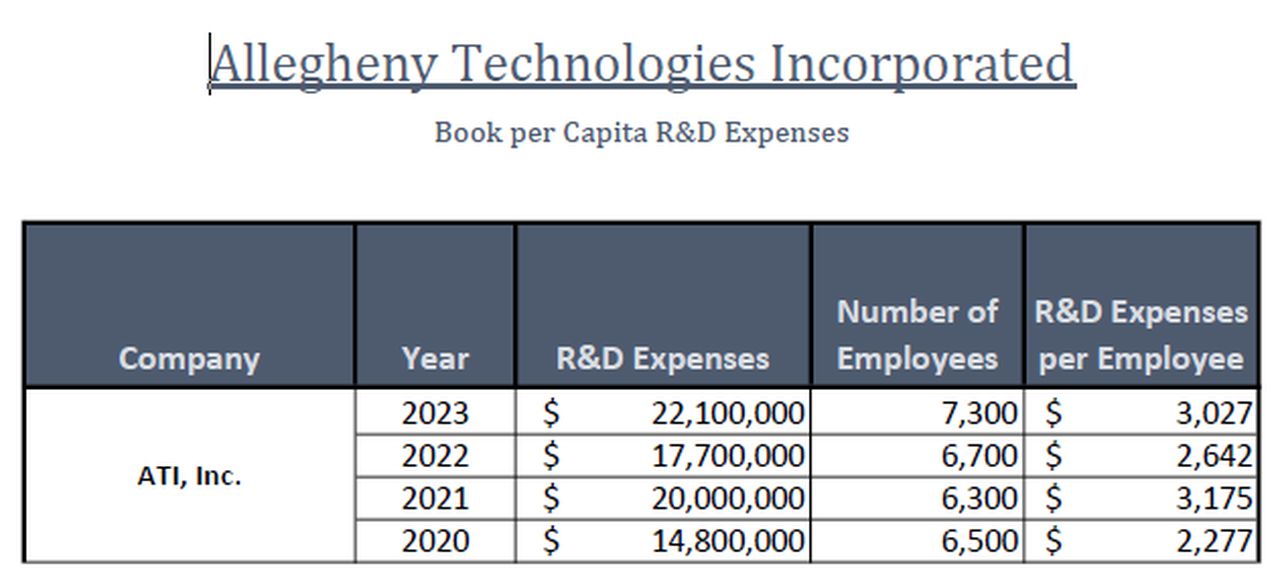

ATI’s commitment to innovation is evident in its steady increase in annual R&D expenditures, which is displayed in the table below.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Allegheny Technologies Incorporated is uniquely positioned to bridge the gap between outdated infrastructure and modern manufacturing capabilities. Whether it’s revitalizing dormant nuclear reactors, supporting military readiness, or powering next-generation data centers, 3D printing stands ready as a transformative technology—and ATI is poised to lead the way. Through its deep expertise in metallurgy and additive manufacturing, ATI can ensure that critical industries continue to operate securely and sustainably in an ever-evolving global landscape.