Charles R. Goulding and Preeti Sulibhavi explore how Huntsville, Alabama, is leveraging 3D printing and emerging technologies to counter workforce reductions and drive economic resilience.

Huntsville, Alabama, often referred to as “Rocket City” due to its pivotal role in the aerospace and defense industries, is currently grappling with significant workforce reductions, approximately ten percent per DOGE mandates. These layoffs have instilled a sense of uncertainty among residents, raising concerns about the local economy’s stability and the future of employment in the region.

Elon Musk has particular expertise when it comes to making space exploration more efficient.

Economic Impact of Workforce Reductions

The recent downsizing in Huntsville’s defense and aerospace sectors has led to widespread anxiety among the city’s workforce. Employees who have dedicated years to these industries now face an uncertain future, prompting questions about job security and economic resilience. The ripple effects of these layoffs extend beyond individual households, potentially influencing local businesses and the broader community.

In response to these challenges, there is a growing emphasis on diversifying skill sets to adapt to the evolving job market.

US Representative, Dale Strong, for the Huntsville, Alabama district has a different viewpoint on this development. He is quoted as saying, “The defense industry and a diverse economy will help offset the loss of federal jobs in Huntsville.”

One promising avenue is the field of additive manufacturing, commonly known as 3D printing. This technology offers innovative solutions across various industries and presents opportunities for workforce reskilling and economic revitalization.

3D Printing Initiatives at the University of Alabama in Huntsville (UAH)

The University of Alabama in Huntsville (UAH) stands at the forefront of 3D printing research and application, spearheading projects that not only advance technology but also provide avenues for workforce development. These initiatives are instrumental in equipping individuals with the skills necessary to thrive in emerging industries.

- Development of 3D Printed Lunar Concrete

Doctoral candidate Ledia Shehu has been awarded a US$150,000 NASA FINESST grant to develop a multiscale model for 3D printed concrete using lunar materials. This project aims to simulate lunar conditions to create sustainable building materials for future space missions. The research not only contributes to space exploration but also enhances the understanding of 3D printing applications in construction, offering potential pathways for professionals transitioning from traditional manufacturing roles.

- 3D Printed Medical Training Devices

Engineering students at UAH have collaborated with the College of Nursing to create 3D printed medical training tools. Devices such as cricothyrotomy trainers and vein finders have been developed to provide nursing students with realistic practice models. This initiative not only improves medical education but also demonstrates the versatility of 3D printing in healthcare, highlighting new career opportunities for those affected by layoffs in other sectors.

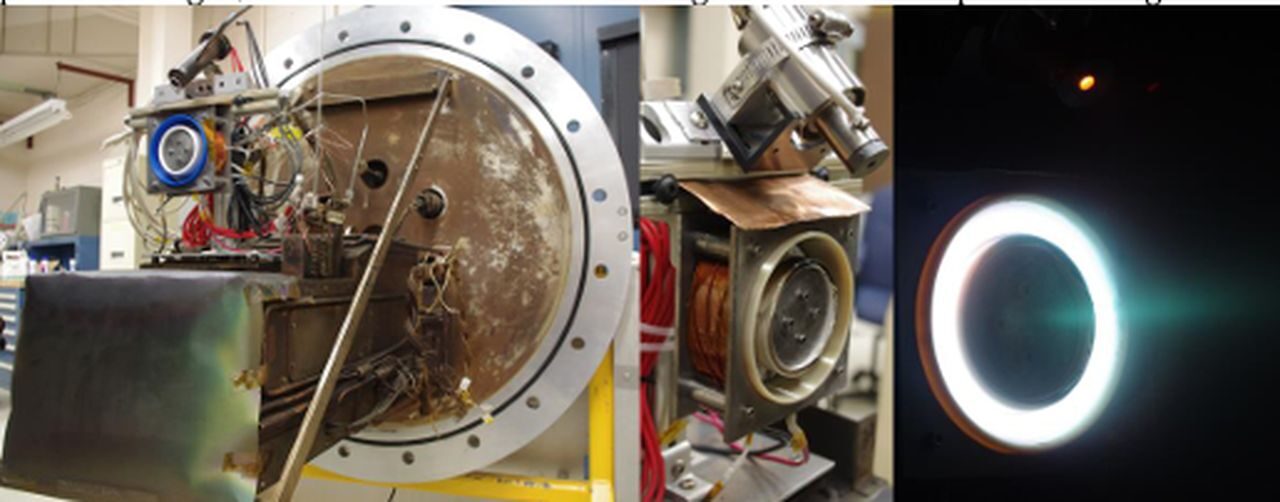

- Design and Testing of a 3D Printed Hall Effect Thruster

In a pioneering project, UAH researchers designed and tested a low-power Hall effect thruster with components manufactured using 3D printing. This endeavor assessed the feasibility of utilizing additive manufacturing to produce cost-effective propulsion systems for spacecraft. The success of this project underscores the potential of 3D printing in aerospace applications, offering a new direction for professionals with backgrounds in traditional aerospace manufacturing.

- MultiMaker Lab: A Hub for Innovation

UAH’s Salmon Library houses the MultiMaker Lab, a space dedicated to fostering creativity and innovation through 3D printing. The lab provides access to 3D printing resources for academic and personal projects, enabling students and community members to explore additive manufacturing technologies. Workshops and events, such as “3D Printing Basics,” are regularly offered to educate participants on the practical applications of 3D printing. This facility serves as a valuable resource for individuals seeking to acquire new skills pertinent to the evolving job market.

3D Printing as a Catalyst for Workforce Reskilling

The integration of 3D printing technologies into various sectors presents a viable solution for workforce reskilling, especially in regions like Huntsville facing industrial transitions. By embracing additive manufacturing, displaced workers can acquire new competencies applicable to a range of industries, from aerospace to healthcare.

Educational institutions like UAH play a crucial role in this transformation by providing training programs and resources that facilitate the adoption of 3D printing skills. These initiatives not only enhance individual employability but also contribute to the diversification and resilience of the local economy.

Firefly Aerospace Reaches the Moon

While this article was being written, a private, Texas-based company called Firefly with a lunar-lander called Blue Ghost, made the second-ever commercial lunar landing. The lunar lander carried a drill, vacuum, and other equipment for NASA. Firefly and the expanding cadre of private space manufacturers, including Intuitive Machines, should be having expanded employment opportunities for Rocket City engineers and technicians.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Huntsville’s recent workforce reductions have undoubtedly introduced challenges; however, they also present an opportunity to pivot towards emerging technologies such as 3D printing. Through strategic initiatives and educational programs, the community can navigate this transition, fostering a workforce equipped for the industries of the future.