Charles R. Goulding and Preeti Sulibhavi explain how impractical design—from baffling car controls to confusing hotel fixtures—can frustrate consumers and highlight how 3D printing offers solutions for improved usability.

The Wall Street Journal has recently highlighted a series of impractical car component designs that consumers find baffling. With modern electronics and sensors making it possible to place controls in unconventional areas, some design choices have proven frustrating for users. One notable article focused on transmission shifters, where even a seasoned Federal highway vehicle tester struggled to locate the transmission controls. This trend poses real-world issues—especially for travelers. Imagine arriving late at a Hertz rental pickup area, eager to begin your trip, only to be unable to operate the vehicle’s transmission. Such poor design can turn an otherwise routine experience into a stressful ordeal.

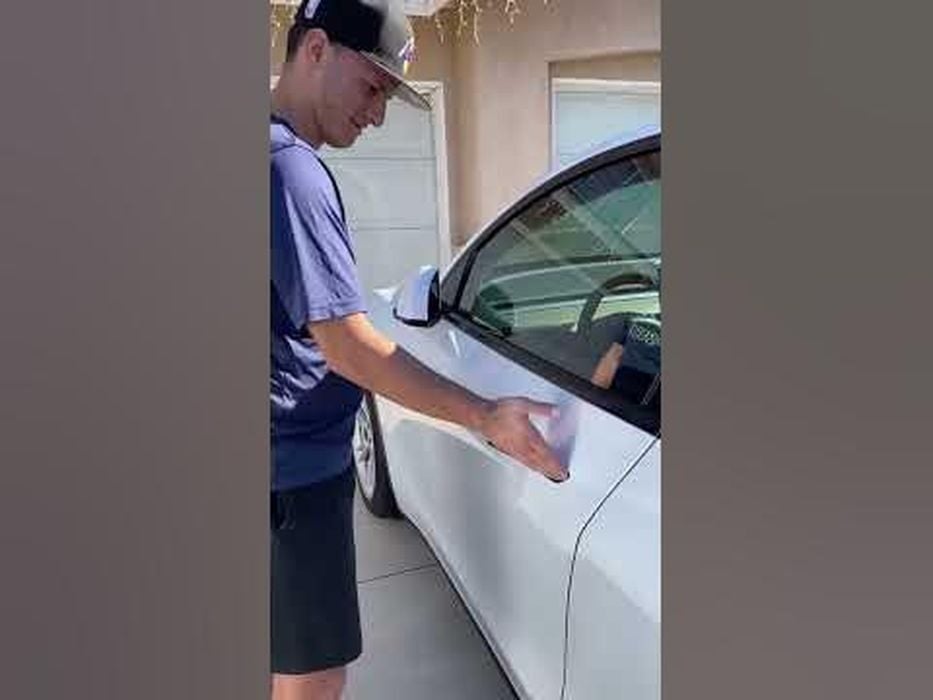

Confusing Car Door Designs

Car door designs have similarly become problematic. Recently, while traveling back from a product design meeting in New Jersey with Mike DiMarino, President of Linda Tool in Brooklyn, I encountered this firsthand. Pressed for time because Mike had an upcoming BBC interview, we stopped at a Brooklyn deli to grab a quick lunch. Mike double-parked, and in the rush, I struggled to exit the vehicle. The door operated via a push-button mechanism, yet I instinctively searched for a traditional handle. The irony was not lost on me—we had just spent three hours in a meeting discussing practical design with Bob Tarantino, a prominent EDM manufacturer, focusing on consumer-friendly kitchen accessories. This experience underscored the critical need for intuitive design principles.

Learning from Toyota’s Approach

Those familiar with Toyota’s history may recall that before entering the U.S. market, Toyota researchers studied American driving habits. They discovered that ample cup holders—which were unfamiliar in the Japanese market—were essential for American drivers. This insight helped Toyota successfully adapt to U.S. consumer needs, reinforcing the value of understanding user behavior before finalizing product designs.

The Challenge of Sink and Shower Controls

Hotel faucets and shower controls are another example where design overcomplication can hinder user experience. Frequent travelers may recognize the frustration of encountering cryptic controls for something as simple as brushing their teeth or taking a shower. In some boutique hotels, these designs are so unconventional that calling the front desk for instructions may become necessary. For travelers arriving late or heading to a dinner engagement with limited time, this design misstep can be more than just an annoyance—it actively disrupts their schedule. Consequently, some travelers avoid designer boutique hotels to bypass these frustrations altogether.

The Role of 3D Printing in Practical Design

The 3D printing industry has increasingly focused on developing customer-relevant applications. The flexibility and precision of 3D printing offer immense potential, but designers must still prioritize functionality. A recent case involved airline engineers failing to account for the impracticality of overhead luggage compartments because they lacked frequent traveler insights. This oversight illustrates the importance of field testing and customer feedback in ensuring usability.

3D printing’s adaptability allows for rapid prototyping and design iteration, making it an ideal tool for refining product designs before large-scale production. For instance, Cadillac’s innovative use of 3D printing in models like the Celestiq and Blackwing series reflects this approach. In the Celestiq, 115 3D printed components enhance customization, reduce weight, and improve structural integrity. Key parts like metal steering wheel centers, window switches, and structural seatbelt D-rings showcase how additive manufacturing can balance complexity with usability.

Similarly, the Blackwing models incorporate 3D printed HVAC ducts and wiring harness brackets, both of which optimize airflow, improve strength, and minimize weight. These design enhancements contribute to Cadillac’s performance focus while maintaining ease of use for drivers.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion: Balancing Innovation with Usability

While technology enables increasingly innovative design choices, designers must remain mindful of user experience. Practicality should remain central to product design, especially in industries like automotive, hospitality, and consumer electronics. The successful integration of 3D printing into manufacturing exemplifies how innovation can coexist with functionality. By involving focus groups, conducting field tests, and embracing consumer feedback, designers can avoid the pitfalls of impractical design. As demonstrated by Toyota’s cup holder insights and Cadillac’s 3D printing advancements, thoughtful design remains key to ensuring consumer satisfaction and product success.