Charles R. Goulding and Preeti Sulibhavi explore how NATO’s push for increased defense spending and the adoption of additive manufacturing technologies are transforming military strategies and sparking debates across member states.

The United States, under the leadership of the current administration, is pushing NATO allies to increase their defense spending as a percentage of GDP from the near agreed 2% threshold to a potential 5%. This significant shift aims to address growing global security concerns, particularly the expansion of military threats from adversaries such as Russia and China. The demand has sparked debates among NATO members regarding their willingness and ability to meet such a steep increase in defense expenditure. This article delves into the economic implications, defense spending trends, and the emerging role of additive manufacturing (3D printing) in modern military strategy.

NATO Members and Current Defense Spending

NATO, comprising 31 member states, has seen varied adherence to the 2% GDP defense spending guideline established at the 2014 Wales Summit. As of 2024, the top five NATO defense spenders are:

- United States: US$886 billion

- United Kingdom: US$72 billion

- Germany: US$70 billion

- France: US$66 billion

- Poland: US$28 billion

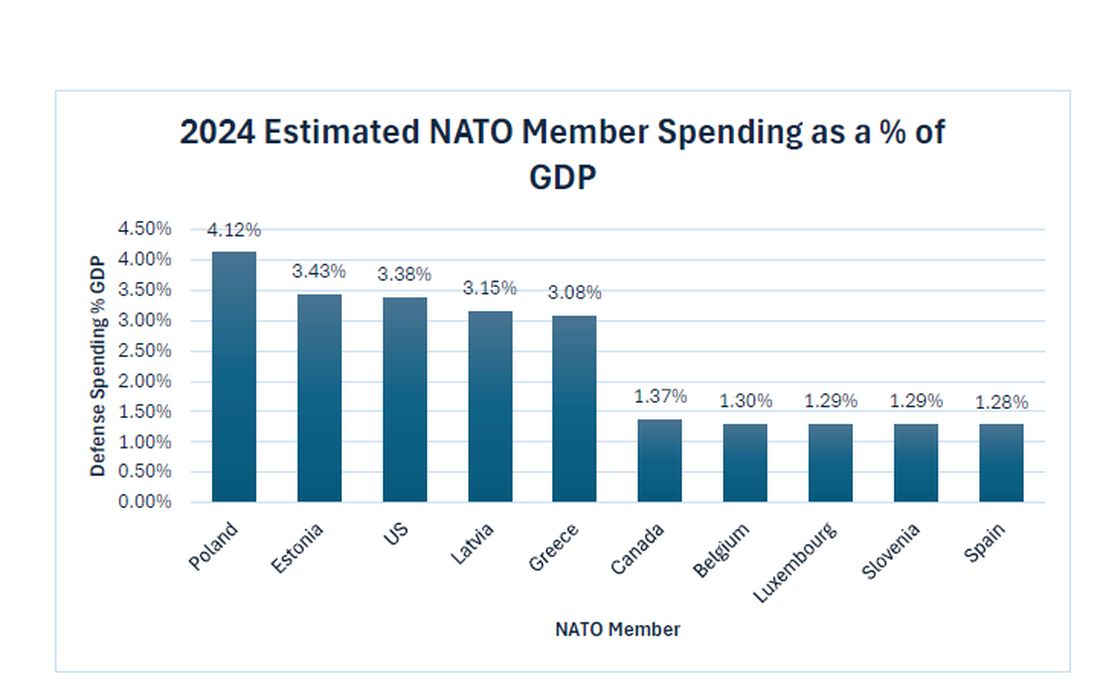

Several member countries, such as Poland and the Baltic states, already exceed 2%, largely driven by their proximity to Russia and heightened security concerns following the invasion of Ukraine in 2022. Poland has indicated that it would be willing and able to reach the 5% benchmark if necessary.

Others, like Germany and France, hover near the threshold, balancing military priorities with domestic economic pressures. Some European countries like Italy and Spain remain below the 2% target, citing fiscal challenges and competing social program demands.

The push toward 5% of GDP would likely strain the budgets of many NATO members, especially those with smaller economies. For instance:

- Luxembourg: With a GDP of US$100 billion, even a 5% target would significantly challenge its budget.

- Greece: Already at approximately 3.7% due to longstanding tensions with Turkey, increasing to 5% would necessitate reallocation from other sectors.

The economic diversity within NATO makes uniform increases in defense spending complex. Wealthier nations like the United States, Germany, and the United Kingdom possess robust economies capable of absorbing the increase. Smaller or economically constrained nations, such as Albania and Montenegro, may find it difficult to allocate such a high percentage without compromising essential services.

2024 projections show that while NATO collectively spends over US$1.2 trillion on defense, the disparity in GDP and spending levels among members creates political tension. The United States has long criticized wealthier allies like Germany for not contributing proportionally, a critique that will only intensify if the 5% goal gains traction.

Increased defense budgets are likely to accelerate the adoption of advanced technologies like additive manufacturing. 3D printing, already a transformative force in industries ranging from healthcare to aerospace, is rapidly becoming a cornerstone of military innovation. Let’s explore its integration among NATO members and the United States.

Currently, the U.S. military spending is below the 5% target so the U.S. will need to increase military spending if it wants to practice what it preaches.

Additive Manufacturing Adoption by NATO Members

- United States: Leading the charge, the U.S. Department of Defense (DoD) has invested heavily in additive manufacturing for research, prototyping, and field applications. Kall six branches of the U.S. military have comprehensive 3D printing initiatives. Key uses include:

- Aerospace components: Manufacturing lightweight, durable parts for aircraft and drones.

- Field repairs: Deployable 3D printers allow troops to produce replacement parts on demand.

- Medical supplies: Printing custom prosthetics and surgical tools in combat zones.

- United Kingdom: The UK’s Ministry of Defense has integrated additive manufacturing in the Royal Navy, using it to produce spare parts for ships and submarines.

- Germany: German defense contractors like Rheinmetall are exploring 3D printed ammunition and armored vehicle components, enhancing cost efficiency and customization.

- France: The French Armed Forces have begun using 3D printing for prototyping and producing parts for advanced weaponry systems.

- Poland: Focused on indigenous development, Poland uses additive manufacturing to create prototypes for its armored vehicles and drones, reducing dependency on foreign suppliers.

U.S. Defense Department’s 3D Printing Applications

The U.S. DoD has made significant strides in additive manufacturing, emphasizing its potential to enhance operational efficiency and readiness. Recent examples include:

- Hypersonic Missiles: In 2024, the DoD announced the successful production of 3D printed components for hypersonic missile prototypes, reducing manufacturing time by 40%.

- Naval Applications: The U.S. Navy deployed on-board 3D printers to create replacement parts for critical systems on aircraft carriers during extended missions.

- Medical Innovations: Field hospitals in conflict zones used 3D printing to produce surgical instruments and bone implants, cutting supply chain dependency.

Challenges to Implementation

Despite its promise, the adoption of additive manufacturing is not without hurdles:

- Initial Investment: The cost of 3D printers and training personnel is high, potentially deterring smaller NATO economies.

- Material Limitations: Some materials essential for military-grade products are not yet suitable for 3D printing.

- Standardization: NATO must establish uniform standards for 3D-printed parts to ensure interoperability across allied forces.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The evolving demands for increased NATO defense spending reflect heightened geopolitical risks and a shift toward modern warfare capabilities. While many member states grapple with economic constraints, additive manufacturing offers a path to innovation and efficiency in defense operations. The expertise gained from increased military 3D printing has dual use in that knowledge gained will spill-over into the civilian economy.

As NATO members debate the feasibility of meeting heightened spending targets, the broader question remains: How can the alliance ensure that increased budgets translate into real-world strategic advantages? The integration of technologies like 3D printing offers a compelling answer, promising to reshape the future of defense in an era of rapid technological evolution.