I had a chat with researchers from the Fraunhofer Institute about high-speed laser metal deposition.

Laser metal deposition is commonly used in the 3D print industry, where metal powder is blown through a nozzle and melted upon impact on the target surface. By adding layer after layer, it’s possible to build up large metal objects. Typically, these toolheads are mounted on robotic arms to perform LMD.

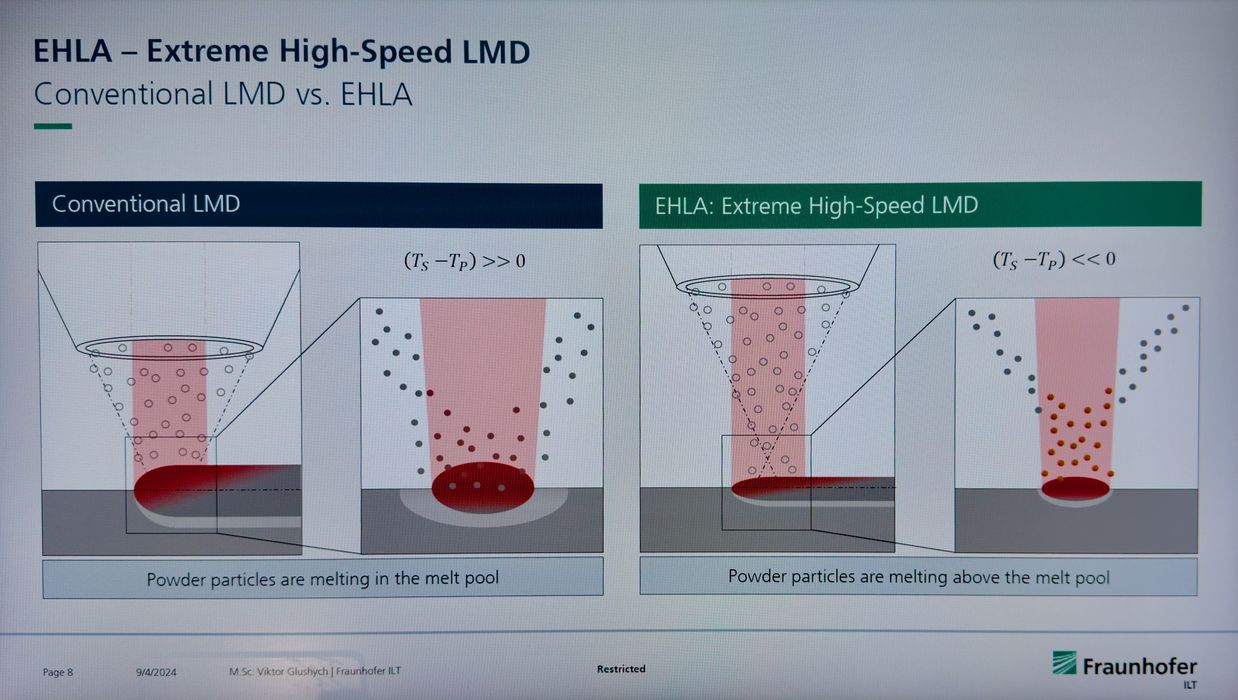

The researchers developed something they call EHLA, or “Extreme High Speed LMD”. This new process allows them to print at vastly higher speeds.

Normally, the speed of LMD printing is governed by the meltpool, the “wet” spot that moves along the surface, heated by the laser. Due to thermal effects, the meltpool can move only so fast.

EHLA is different in that they melt the metal particles before they impact the target surface. In other words, they are melted as they fly through the laser beam. They then splatter onto the surface, completing the job.

How fast can this be done? The researchers explained that it is so fast that they find that using it on rotating surfaces is better because higher speeds can be achieved. The pre-heated target spins quite quickly and gets layered with metal by the EHLA process. They said the biggest issue is getting enough powder into the process zone so that it’s not constrained by the melting process.

Another interesting advantage of EHLA is that it is far more power-efficient. In typical LMD scenarios, they are only 60-70% efficient because some of the energy is absorbed by nearby structures.

In contrast, the flying metal particles absorb almost all the energy from the laser. They say EHLA can achieve around 95% power efficiency.

A platform for the implementation of EHLA is being constructed by Ponticon, so we may see this emerge soon under their new brand name, pE3D. They say the machine may be able to print up to ten times faster.

Via Ponticon