Formlabs announced a slew of new products and materials today.

The announcements provided enhancements for both their SLA and SLS 3D print systems in both hardware and software.

Formlabs followed their usual pattern of adding to their ever-expanding catalog of in-house materials for their SLA systems with the addition of a new casting material that is said to offer improved performance.

The surprise, however, was their announcement of their very first certified third party material.

To date Formlabs material strategy has been two-fold: a selection of internal materials and an “open materials mode”, where the operator can use any material, but they’re on their own.

Now they’ve certified a third party material, BEGO VarseoSmile TrinQ Resin, used for production of permanent bridges for dental applications. With this addition, Formlabs now has three categories of materials, in-house, certified, and you’re-on-your-own.

This approach has long been used by other 3D printer manufacturers, with some providing vast databases of print profiles to handle materials from many third party suppliers. It seems that Formlabs might head in this direction after today’s announcement. In the future we may see a long list of certified third party materials for Formlabs equipment, which will certainly make their equipment even more desirable.

But that’s not all. The company also announced three hardware accessories.

There’s a new polishing system for the Fuse Blast, which smooths printed SLS parts after sifting. Formlabs said this produces “semi-gloss, scuff-resistant, and dye-ready surface finishes”. They also introduced a handle system to streamline part extraction from the Fuse Sift.

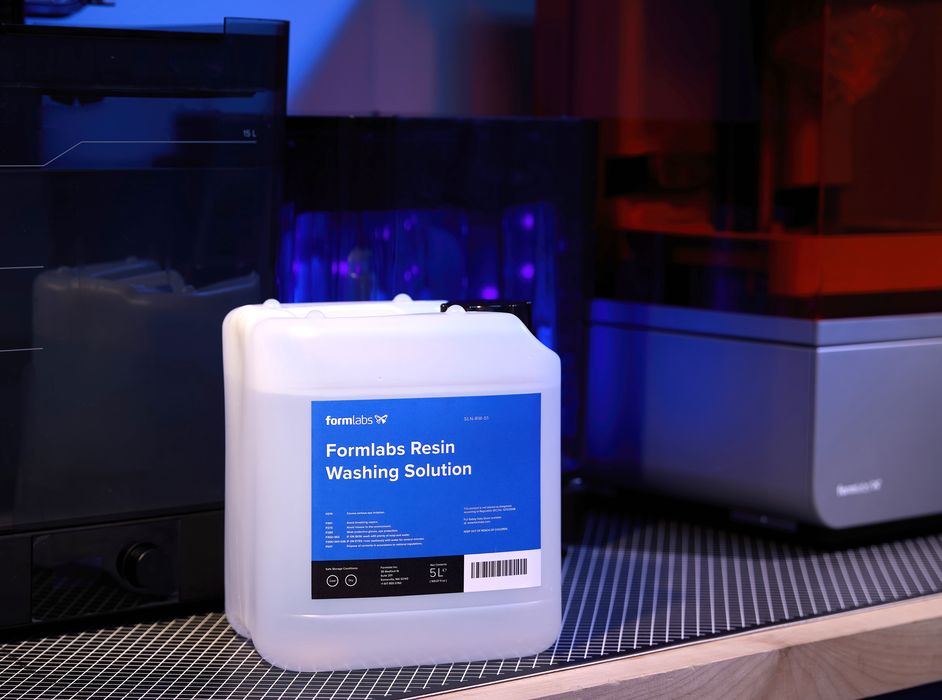

Finally, there’s an intriguing new wash solution for their SLA systems. The new Formlabs Resin Washing Solution is a liquid wash agent that is intended to substitute for IPA, the traditional washing solvent for resin 3D prints. IPA is effective, but has the disadvantage of being highly flammable.

The new solution is not only non-flammable, but is also said to “dissolve twice as much resin before becoming saturated”. Formlabs also describes the new solution as “safe for any workspace”.

The double saturation feature means that less solution would be required for production, and Formlabs said this allows for lower overall costs per part.

Via Formlabs