This has to be one of the strangest things I’ve seen in 3D printing: a foldable 3D printer design.

The design looks quite unreal, and at first glance I would discount this as “fake”.

But is it? This design was presented with the iF Design Award for 2025. iF Design is a 70-year-old organization that presents design awards to worthy submissions. They have a comprehensive process to judge the entrants, and a final jury makes the decisions. This seems quite legit.

Back to that 3D printer design. Here’s the description:

“This is a foldable, portable 3D printer that solves the issue of large, cumbersome printers. Featuring five rotational axes, it can fold completely and allows the print head to stop at any position, enabling various sizes of 3D printing. When folded, it measures just 75mm in height, making it comparable to a briefcase for easy transport. This design transforms a desktop device into a mobile one, allowing designers, engineers, and makers to work anywhere. It offers high-precision printing with a maximum height of 460mm, while its multi-axis arms provide an engaging experience. The angled control interface enhances user interaction.”

I am very skeptical of the practicality of this 3D printer design for a variety of reasons I’ll get into. Because of that, I was again almost ready to discount this design. But then I saw the name of the submitter:

“Shenzhen Anycubic Technology Co., Ltd.”

Hold on, that’s a very notable 3D printer manufacturer. I have multiple devices from them, and am literally printing something on one right now.

Could this be a product concept for their future?

There is absolutely no indication from the company about this design concept. I’m half wondering if they are even aware of this? Did someone use their name when submitting the entry?

Anyway, let’s look at the 3D printer from a technical viewpoint.

Could this design work? I believe it could, but with a number of challenges. Here are some thoughts:

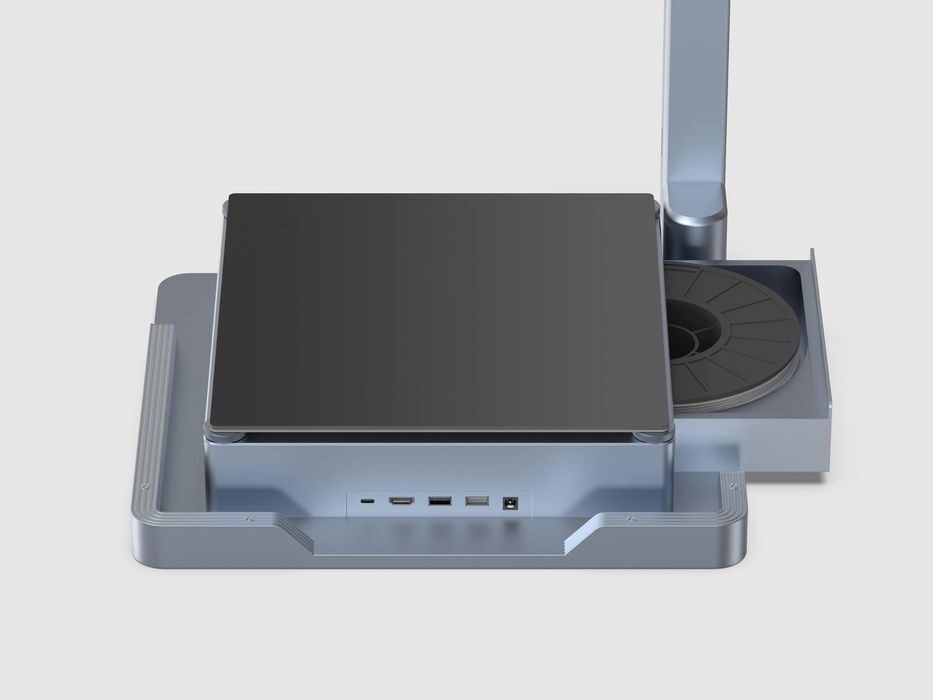

- Where does the spool go? It seems to be underneath the printer, but it appears much smaller than a standard spool of today.

- How accurate is the positioning of the toolhead? This could affect print quality significantly.

- The robotic motion system could enable more advanced non-planar extrusions to overcome the need for support material.

- A completely new slicing tool is required.

- Material compatibility would be very limited by the unenclosed build volume.

- Leveling would be done by probing the print plate with the robotic toolhead.

- How does cooling work? There does not seem to be any way to blow cold air on freshly extruded portions.

- I’m concerned about how the filament path works. The filament follows a PTFE tube on the arm, but would filaments of different hardness cause problems with movement?

- How durable is this design? The precision required of the motion system might be quite sensitive to bumps and drops if it’s truly portable.

- It looks like the robotic arm docks on the right-hand side of the base after wrapping over the control panel.

- Robotic arms can be expensive. Would this design be expensive?

There are quite a number of concerns about this design approach for a desktop 3D printer. While it probably could be made to work, it would be a huge effort because of all the differences from today’s machines.

If you did all that work, you’d end up with a machine that likely would have poor capabilities but the ability to fold up and be transported.

Is that really worth all the effort? I am not so sure, and perhaps that’s why it doesn’t appear anywhere on Anycubic’s website.

Via iF Design