Farsoon announced a metal 3D printer with a record 32 lasers.

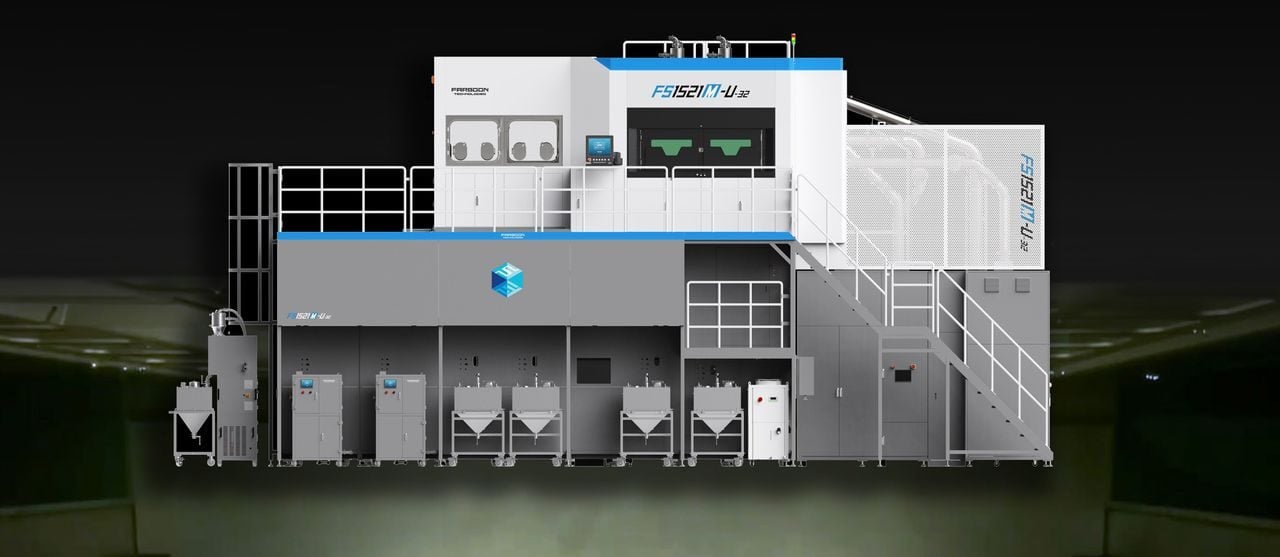

The new Farsoon FS1521M-U, an enormous machine pictured above, can be equipped with an unbelievable 32 lasers.

The increase in the number of lasers in large format LBPF metal 3D printers has been progressing upwards in recent years. Initial machines used a single laser, but it was realized that a second laser could nearly double the throughput of the device because of parallel operation.

Many machines now have dual lasers, and four-laser systems are also becoming relatively common. A few systems exceed four, with one of the notables being Nikon SLM Solution’s NXG XII 600, which broke records when it was announced with twelve lasers.

Farsoon has now far exceeded that mark with up to 32 500W lasers, with a starter configuration of “only” 16 lasers. These operate in the standard build volume of 1530 × 1530 × 850 mm. There’s also a “high” configuration with an even bigger build volume of 1530 × 1530 × 1650 mm.

Does this actually speed up printing? While results will obviously depend on the specifics of the parts involved, Farsoon terms the speed benefits as “significant”.

An unusual feature of this device is that it can be configured with either a cylindrical or cubic build volume, perhaps the first machine I’ve heard of that has this capability.

The FS1521M-U includes four powder hoppers that can keep the machine busy on large jobs, and up to four powder recycling units that can deliver up to a whopping 360l of clean powder each hour.

At the same time as the FS1521M-U announcement, Farsoon also announced a new “beam shaping technology”. This feature is now available on four Farsoon systems, but unfortunately not on the FS1521M-U, at least not yet.

The beam shaping tech enables operators to change the shape of the laser dot that transfers energy to the powder. Normally, the dot is a simple circle (or ellipse as the dot is distorted in the corners of the build area). With beam shaping technology, there are many more possibilities. Farsoon explains:

“Farsoon’s unique Beam Shaping Technology enables laser spots to be dynamically formed into various shapes, such as ring-shaped, point-ring-shaped, or fully customizable configurations tailored to specific application requirements. When combined with high-power lasers and optimized scanning strategies, this technology significantly enhances printing quality and efficiency for materials like stainless steel, aluminum alloys, and titanium alloys, achieving part densities exceeding 99.95%.”

This is quite an interesting feature, although it could add significantly to complexity in setting up print jobs — it’s basically another knob to turn when preparing jobs. However, that complexity could enable the achievement of part quality levels not previously attainable.

Via Farsoon