A new research paper investigates a category of 3D printing I didn’t even realize existed: Field-assisted additive manufacturing, or FAAM.

FAAM is not an acronym commonly used in the technology, as it refers to a group of 3D printing processes that have a common property: leveraging the use of fields.

What are “fields”? In their analysis, they include magnetic fields, acoustical fields and electrical fields.

Why would you want to use fields in 3D printing? There are some interesting advantages because these fields can actually penetrate into the material being 3D printing during print jobs. That access can then help shape the properties of the resulting parts.

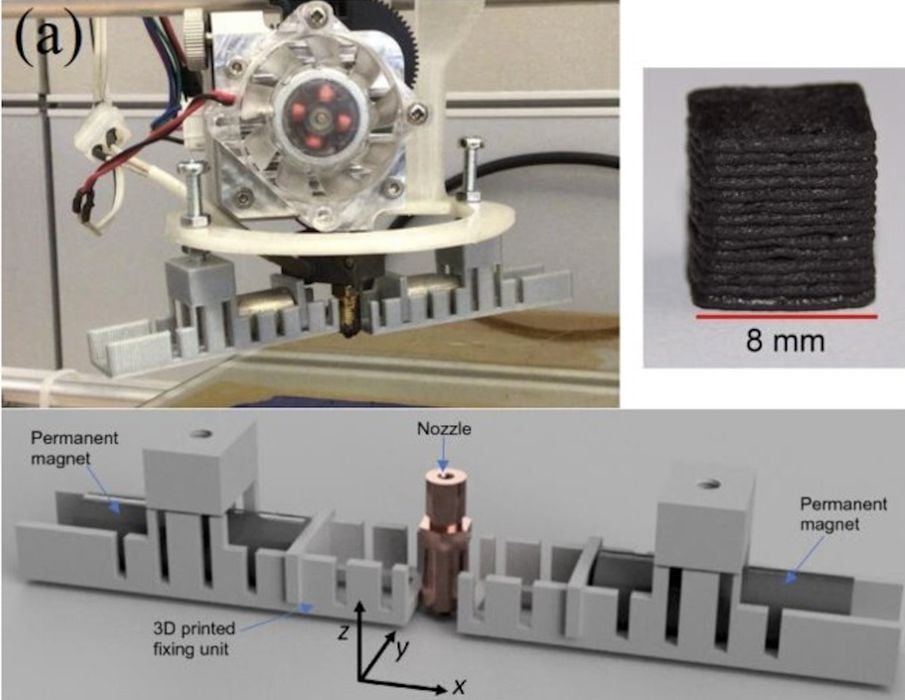

Magnetic fields could be used in this way: a material might have embedded particles that happen to be magnetic. While the print takes place, these particles could be automatically oriented with a suitable magnetic field. If oriented in the best way, they could increase the strength of the part.

Electric field-assisted 3D printing can control particle orientation and distribution in polymers and metals. This can be used with electrostatically-assisted DIW 3D printing and a process know as electric field fabrication (EFF).

Acoustic, or sound-driven, field-assisted printing uses sound fields to manipulate particle distribution and orientation in polymers and metals. These can be quite important to ensure part strength along specified axes. This approach is used in two-photon 3D printing (TPP) and can also be used in ultrasonic laser additive manufacturing (ULAM).

The researchers propose that future research should focus on developing new materials to take full advantage of FAAM technologies, which couldd improve process reliability and quality control.

This echoes developments in earlier 3D printing processes, which didn’t really take off until specific materials were made available for use. In most cases, parts are intended to be produced with specific materials, so if they aren’t available for 3D printing, alternative manufacturing methods must be used.

The same could be true in the FAAM area: if more materials were available that made use of acoustic, magnetic or electric fields there could be increased use of FAAM technology.

This in turn could lead to the creation of tailored anisotropic composites and multifunctional parts with enhanced mechanical, thermal, and electrical properties.

Field-assisted additive manufacturing (FAAM) is a promising, but very underused approach to overcoming current limitations in 3D printing. By employing external fields, FAAM can achieve better control over material properties and microstructures, enabling the fabrication of advanced composites and multifunctional parts. Further research and development in this field are essential for realizing its full potential across various industries.