Evolve Additive has made some big enhancements to their 3D print technology.

The Minnesota company is developing a new style of 3D printing that’s specifically designed for large-scale manufacturing. This is quite unlike most of the 3D printers on the market, which are essentially scaled-up prototyping devices.

Evolve’s technology is a mass-production focused system that can print in polymers. At the moment they offer ABS and PA11, but the technology is clearly capable of doing much more. They’re still at an early stage, so it’s likely they will add more materials as time passes.

Their technology is called “STEP”, for “selective thermoplastic electrophotographic process”. It uses powder as the input material. The powder is picked up by a rotating drum that’s electrostatically charged. The drum then rolls the powder a belt that in turn deposits the material onto the print surface, where it then undergoes heat and pressure to complete the layer. This is reminiscent of old photocopy devices that used a similar approach, but for single-layer 2D paper printing.

The STEP process can be very fast: imagine the drum quickly rolling over the print surface. It can also be scaled up considerably. These properties are ideal for large scale manufacturing, and that’s why I believe Evolve Additive could be one of the big winners in a future where manufacturing adopts 3D print technologies.

It enables larger-scale production without the constraints of injection molding. That allows part designers much more freedom to create unique parts and features.

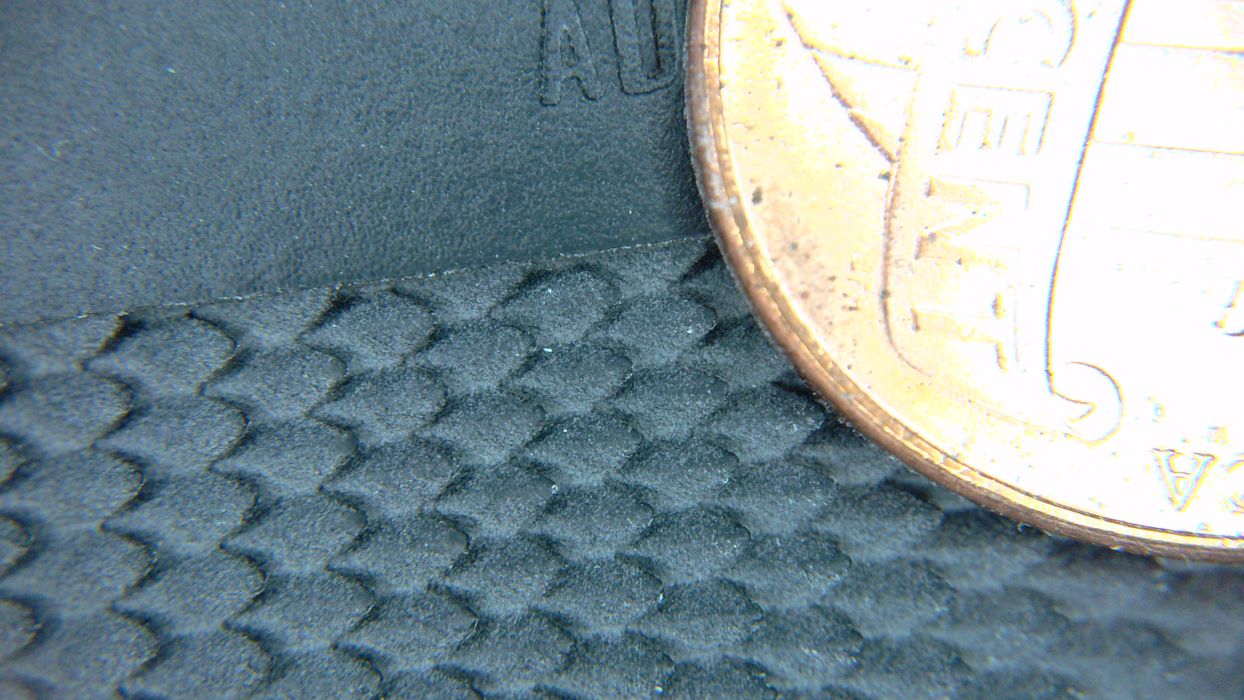

STEP is also high resolution. According to Evolve Additive, the layers are 0.013mm tall, and the particles are 0.022mm in diameter. This makes it possible to produce “ultra smooth” parts directly from the printer.

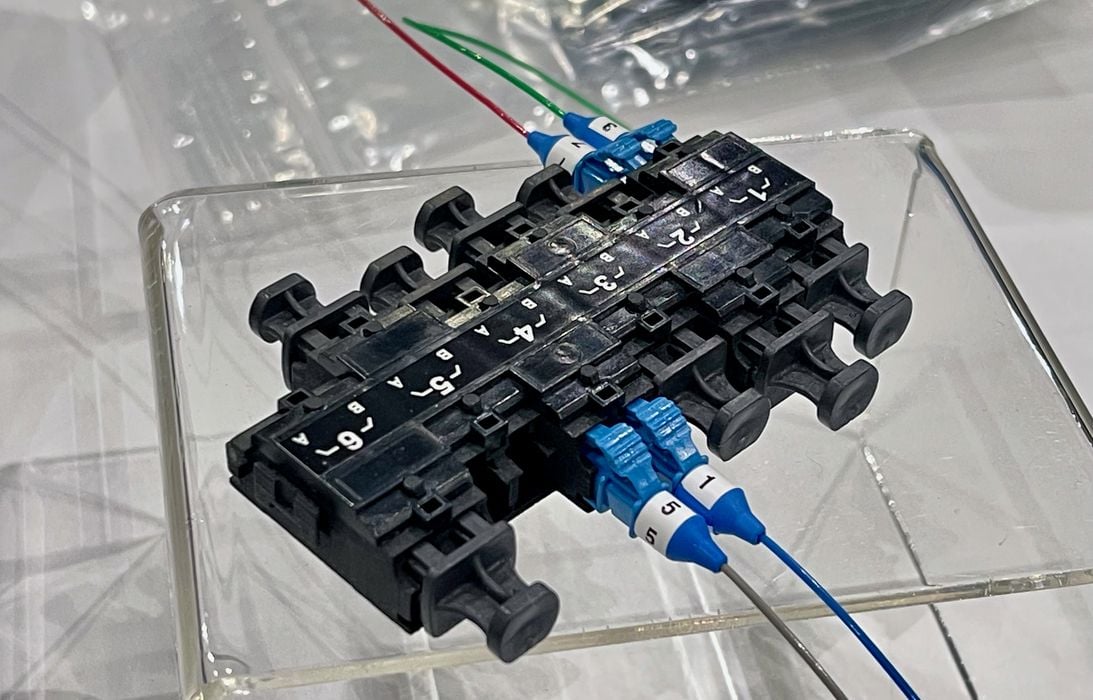

STEP prints parts in a block, as shown at top. Parts are laid out in a 3D fashion, as support material is deposited between parts. This support material is then quickly washed out after the print completes. Because of the superior surface quality and lack of attached supports, there is very little post processing required.

There have been some developments in STEP technology. Evolve Additive informs us that they’ve increased the height of their print platform from 50 to 100 mm. That allows not only larger parts, but basically doubles the part throughput: twice as many small parts can be made in a single job.

We were also told that the company is developing multimaterial capabilities for STEP. Currently their equipment can handle three print engines, and they are working on a fourth. The system as designed can theoretically reach five in the future.

If Evolve Additive’s multimaterial approach works, it might be possible to mass produce 3D printed objects in several materials. I can imagine mixing in flexible with rigid materials, or providing different color options.

STEP is a fascinating technology that we’re certainly going to hear a lot more about in the future.

Via Evolve Additive