There’s been a copper development from Eplus3D.

The industrial 3D printer manufacturer produces some of the largest metal 3D printers on the planet. Some of their machines are the size of small buildings and even include steps and railings to get up to the control panel.

Eplus3D customers use their enormous metal 3D printers to produce large metal parts for industry, especially in the aerospace and energy sectors.

Recently Eplus3D showed off a new red laser technology that apparently enables effective printing of copper material.

Copper is a highly desirable material for many parts because it has a number of useful properties. These include electrical conductivity, thermal conductivity, reflectivity, and even chemical properties. It’s ideal for use in heat exchangers, for example, where the thermal conductivity makes them highly efficient.

That’s all very good, except that it turns out copper is incredibly challenging to 3D print. Typical LPBF systems have problems with copper for two reasons. First, the reflectivity of copper tends to bounce laser beams around unpredictably, making a mess of the job. Secondly, the high thermal conductivity of the material causes heat to rapidly spread away from the meltpool, messing with the precise temperatures required for proper quality prints.

Many 3D printer manufacturers have been working on ways to enable true copper printing, and a few have come up with approaches that work. Now it’s Eplus3D’s turn.

They’ve implemented a new “red laser” tech that overcomes some of these difficulties. They explain:

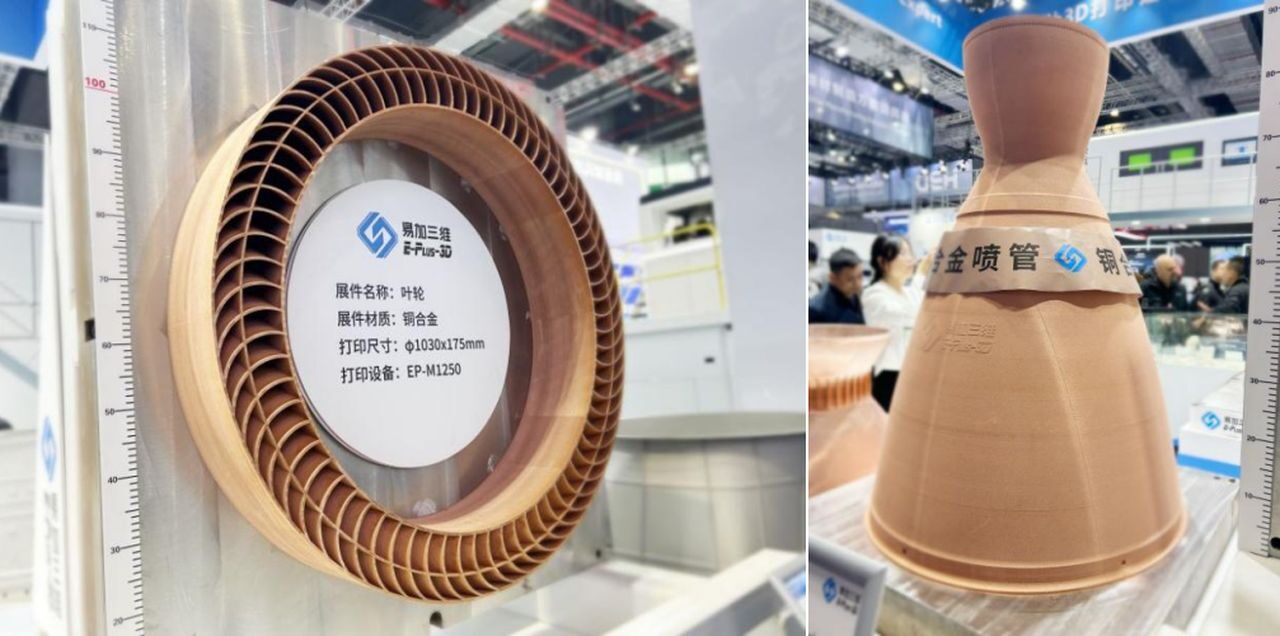

“At TCT Asia 2025, Eplus3D proudly showcased multiple successful examples of meter-scale copper alloy parts, demonstrating that the company has effectively overcome these challenges without the need for hardware upgrades. One of the standout achievements is the production of a φ1030×175 mm copper alloy impeller on the EP-M1250 system. This component boasts an impressive 99.97% density and retains copper’s exceptional thermal conductivity— critical metrics for applications in aerospace thermal management systems.”

It seems this is not a hardware change but rather deals with careful tuning of print parameters combined with a specific copper material.

This is a notable development because most of the other systems that have been able to 3D print copper material are small. Eplus3D’s systems, on the other hand, are enormous. Being able to 3D print a one-meter-sized copper object is quite an achievement.

At the top, you can see two very large examples of huge copper 3D prints that demonstrate what this new technology can achieve. It should be interesting to see what large copper applications will now become possible.

Via Eplus3D