Charles R. Goulding and Preeti Sulibhavi delve into how Stabilus’s acquisition of De-Sta-Co and the integration of 3D printing technologies are set to revolutionize the engineering and motion control sectors.

In a recent acquisition transaction, Stabilus of Germany acquired Dover Corporation’s De-Sta-Co business for US$285 million in cash, and US$680 million in enterprise value. The transaction, announced in late 2023, brings together two innovative players in the field of engineering, automation and motion control solutions.

Stabilus is a global manufacturer of motion control products and engineered components for a variety of industries including automotive, industrial, furniture, energy, and aerospace. The company’s product portfolio includes gas springs, hydraulic dampers, electric motors and actuators used for motion control applications.

Another leading manufacturer of motion control products is Parker Hannifin. Parker is an American company that has become a global leader in motion and control technologies. Headquartered in Cleveland, Ohio, the company works tirelessly to engineer solutions that improve people’s lives while protecting the environment. Parker’s work spans a variety of industries such as the aerospace industry, digital, healthcare, transportation, off-road machinery, oil and gas, and HVAC & refrigeration.

The acquisition of De-Sta-Co allows Stabilus to significantly expand its product offering and geographic reach in the industrial automation and workholding markets. De-Sta-Co is a leading provider of workholding equipment, remote handling tools and industrial automation solutions for aerospace, automotive and marine with a strong presence in North America.

“This transaction is a major strategic step in our efforts to grow our industrial business while also diversifying into attractive new markets and regions,” said Dr. Stephan Kessel, CEO of Stabilus. “De-Sta-Co’s proven product quality, superior application expertise and excellent customer service are a perfect match for Stabilus.”

The combined company will have over 6,500 employees across more than 16 countries, serving customers in 80 nations, globally. Stabilus expects the acquisition to create significant value through cross-selling opportunities, cost synergies and sharing of technological expertise.

While Stabilus and De-Sta-Co are well-positioned now to be a combined economic powerhouse, both companies are also embracing innovations like 3D printing to enhance product development and manufacturing capabilities.

3D Printing at Stabilus and De-Sta-Co

One of the subsidiaries under the Stabilus umbrella is General Aerospace GmbH, a leading manufacturer of aircraft interior equipment based in Germany. General Aerospace has been an early adopter of 3D printing technology for producing interior cabin components.

In 2022, the company unveiled a new line of 3D printed overhead stowage bins designed to be lighter and more spacious than conventional designs. The bins are produced using an industrial polymer 3D printing process that allows for complex geometries and integrated functional features that are difficult to achieve through traditional manufacturing methods.

The 3D printed overhead bins offer a weight reduction of up to 30% compared to injection-molded versions, resulting in lower fuel consumption and reduced carbon emissions for airlines. In addition to the environmental benefits, the optimized fluid internal geometries of the 3D printed bins provide more headroom and storage space for passengers.

De-Sta-Co has also been leveraging 3D printing to develop new products and improve existing designs. One example is the company’s 3D printed Robogrip remote handling tool used in nuclear facilities and other hazardous environments.

The Robogrip features an intricate gripper mechanism produced through 3D printing that allows it to securely grasp and manipulate objects in tight spaces from a safe distance. The 3D printed design consolidates numerous components into a single part, improving functionality while reducing manufacturing complexity and costs.

At Stabilus’s headquarters in Germany, engineers are exploring industrial-grade metal 3D printing processes like selective laser melting to produce functional prototypes and end-use components for the company’s gas springs and dampers.

In 2023, Stabilus announced a partnership with a leading additive manufacturing service provider to insource the 3D printing of production tools and fixtures. The move allows for faster design iterations, improved manufacturing flexibility, and the ability to produce complex geometries that are difficult or impossible with conventional manufacturing techniques.

The Future of 3D Printing in Motion Control

As 3D printing capabilities continue to advance across materials, processes and equipment, the technology is expected to play an increasingly prominent role in the product development and manufacturing strategies of companies like Stabilus and De-Sta-Co.

“Additive manufacturing offers tremendous potential for improving the performance and functionality of our motion control solutions while reducing weight, waste and overall production costs,” said Kessel. “We see 3D printing as a key enabler for delivering more sustainable and innovative products to our customers across industries.”

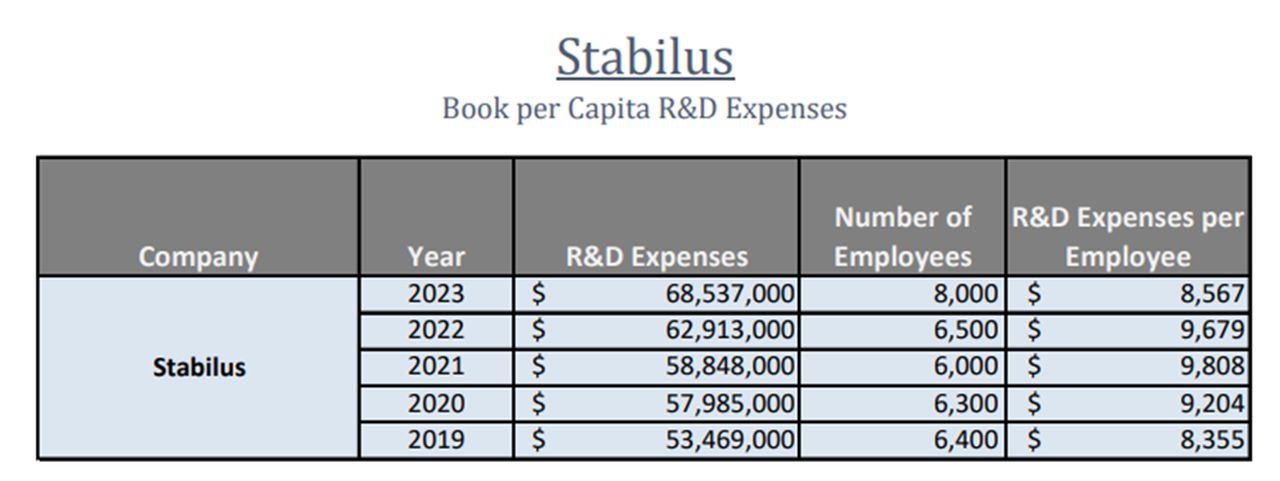

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

From optimized aircraft interior components and remote handling tools to next-generation gas springs and dampers, 3D printing is empowering engineers at Stabilus, De-Sta-Co and their subsidiaries to push the boundaries of design for products that span a whole host of industries.

As adoption of the technology continues to grow within manufacturing sectors like aerospace, automotive and industrial automation, the impact of 3D printing on motion control products, and engineered and automation solutions is poised to increase substantially in the years ahead.