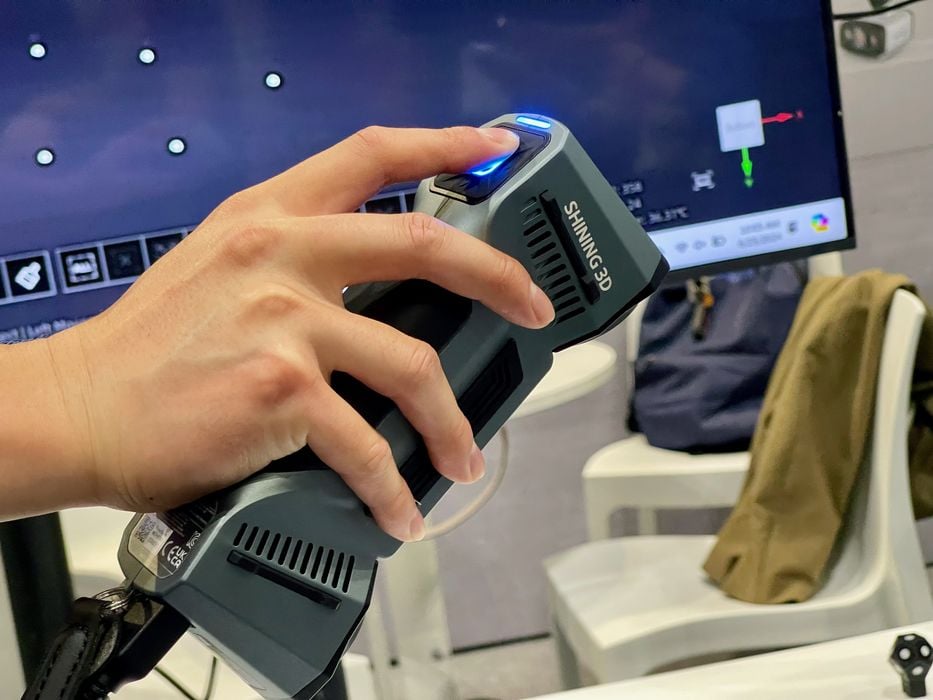

We had a quick look at the new Shining 3D FreeScan Combo 3D scanners.

The FreeScan Combo series is a powerful tool usable by industry. It’s a portable device that’s quite lightweight, and offers two different scanning technologies in the same package.

What are these technologies? The first is a blue laser, which delivers a structured pattern of 50 laser lines (on the Combo+, 26 on the base Combo) during scanning operations. This is quite a detailed pattern that more easily picks up fine details as it is swept along the subject’s surfaces. The Combo’s laser can capture up to 1.8M points per second, with the Combo+ achieving an amazing 3.6M points per second.

The larger scanning area means you can complete scans of big objects in, according to Shining3D representatives, half the time.

The second technology is VCSEL (Vertical Cavity Surface Emitting Laser). This is a semiconductor technology that provides a lightweight infrared laser capability without the need for cooling. It’s ideal for a portable application, such as a 3D scanner.

The two technologies offer different advantages and disadvantages, and typically a 3D scanner will have one or the other, resulting in compromises. Here the Combo series has both, and thus the advantages of both can be achieved.

The FreeScan combo can achieve accuracy of up to 0.02mm. It offers a working distance of around 300mm, with a maximum field of view of around 500 x 500 mm. With this it is easy to quickly scan reasonably large parts.

While the FreeScan Combo units must be cabled to a nearby PC running the software, the scanner itself weighs only 620g, making it fairly easy to move around while scanning.

Both the laser and VCSEL are class II, meaning they are “eye safe”.

What can it be used for? The typical applications would be metrology, where completed parts are scanned to ensure they meet specifications.

The other, and perhaps more frequent use, is reverse engineering. The scan can capture the geometry of a part, and that scan can be transformed into a full CAD model for modifications.

However, that process can be quite tedious. For this task Shining 3D provides a specialized software tool, ExModel Pro.

This software can greatly assist with reverse engineering, as it can automatically recognize geometry in a raw 3D scan, including planes, curves, etc. These are then built into a CAD model for export and use in other programs.

The FreeScan Combo series is designed for industry use, and is priced at US$18,499.

Via Shining 3D