Boston-based Desktop Metal has announced the launch of Live Inspect, a new software for analyzing and correcting errors in 3D printed parts.

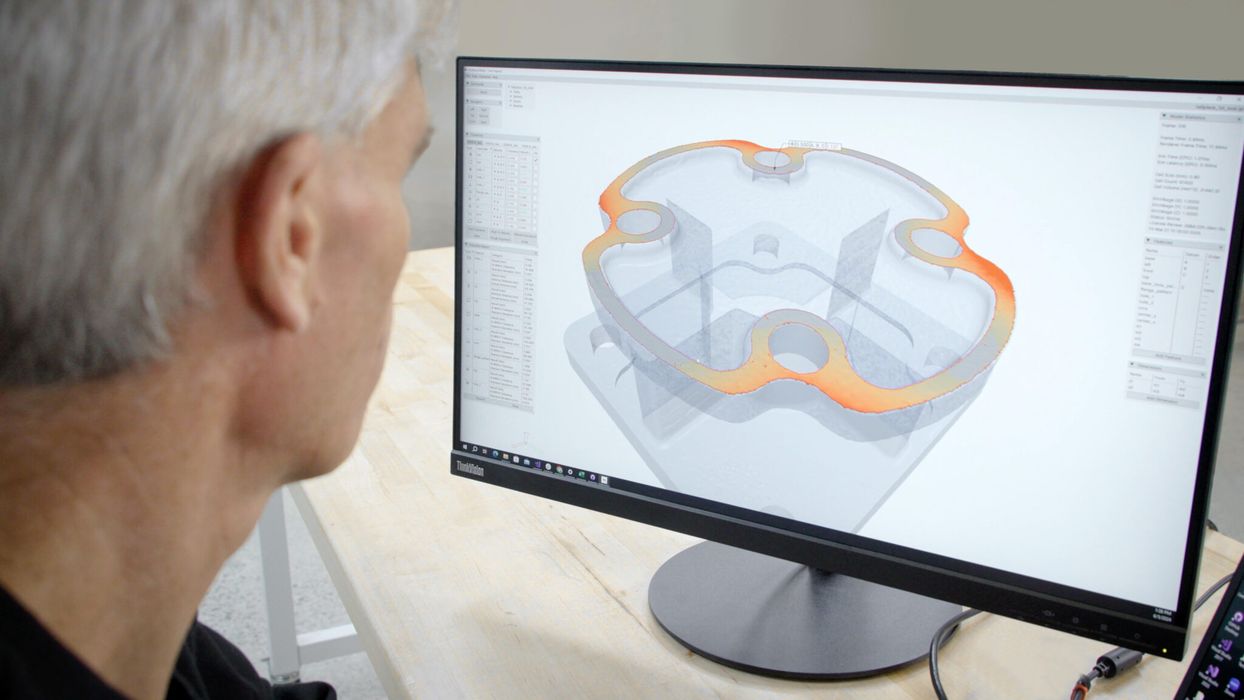

Part of Desktop Metal’s Live Suite portfolio, Live Inspect is designed to allow manufacturers to dial in accuracy and 3D print parts with higher tolerances. The software analyzes features on a 3D scan — such as holes, slots, and planar surfaces — and provides tolerance analysis according to standard geometric dimensioning and tolerancing (GD&T) norms and practices. Live Inspect then automatically applies feature-level scan adjustments that correct for deviations identified by the tolerance-based scan analysis.

Many users of additive technologies use 3D scanners to verify part tolerances. While some tools provide an analysis of these scans, Live Inspect both analyzes and corrects for 3D printing variations.

“Our team developed Live Inspect with the goal of delivering 3D printed results as true to CAD designs as possible,” said Ric Fulop, Desktop Metal Co-Founder and CEO in a press release. “This solution can affect how compensation is applied to 3D scans through user-identified datums that allows them to fine tune prints and hit higher tolerances in production.”

According to the company, users of Desktop Metal’s binder jetting platforms will also benefit from Live Inspect’s enhancements to the capabilities of Live Sinter, Desktop Metal’s sintering simulation and compensation software.

In addition to dealing with powder metal shrinkage and distortion due to density variations, gravity and friction during sintering, Desktop Metal claims that Live Inspect can also aid in the manufacturing of polymer parts that experience warping due to curing and thermal effects or sandcasting cores swelling due to microwave curing.

Read the rest of this story at ENGINEERING.com