This week’s selection is the Ultimate Filament Spool Enclosure for AMS Lite by Makerworld contributor Supergrapher.

The AMS Lite is perhaps the most popular low-cost filament-switching device on the 3D printer market these days, as it’s associated with the very popular Bambu Lab A1 3D printer. It holds up to four spools of filament simultaneously, and can swap colors in mid-print. It works very well, and I have two of them that work flawlessly.

There’s one catch with the AMS Lite: it’s open to the air. Competing filament swapping systems tend to be enclosed affairs, such as the full-on AMS from Bambu Lab, Anycubic’s ACE PRO and similar accessories. Because they are enclosed it’s possible to do some dehumidification of the filament by adding desiccant. In fact, the ACE PRO includes hardware to perform drying right from the factory.

Dry filament is always a good idea, as humidity can wreak havoc on print jobs: inconsistent print reliability, weak parts and surface quality issues. Many 3D printer operators now regularly dry their filament to overcome these problems.

But you can’t easily do that with the AMS Lite because it’s all open to the air.

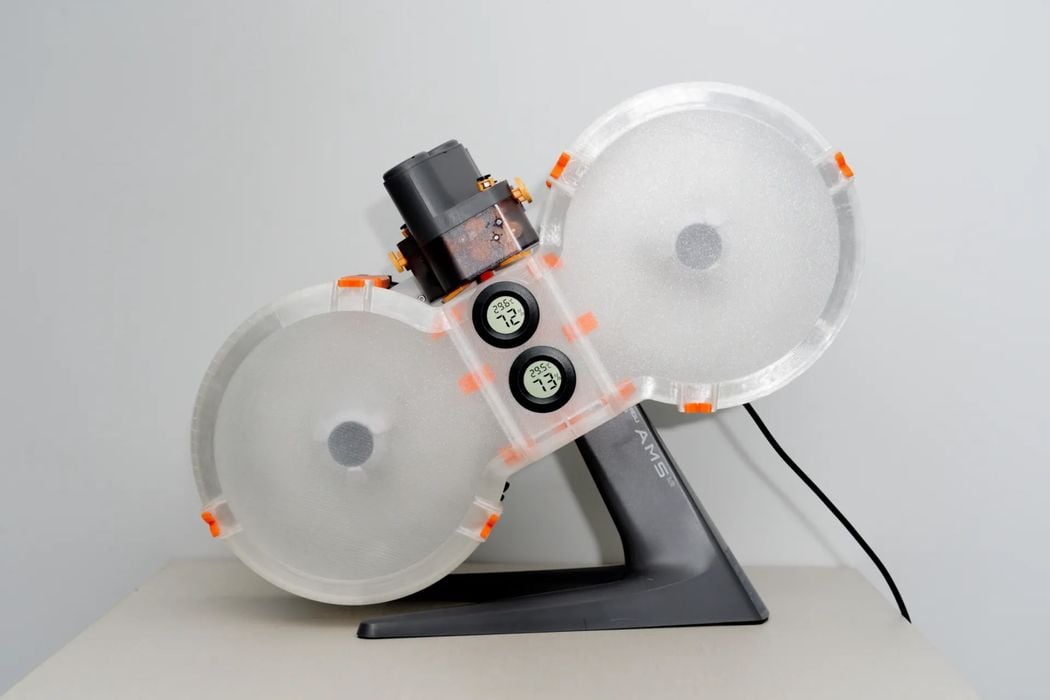

That changes with this design, which provides a kind of case that snaps overtop of the AMS Lite spools to fully enclose them.

The design also accommodates a built-in hygrometer to measure the humidity in the case. These are easily obtained online at low cost. This is not 3D printed itself, but simply snaps into the mounting point.

An internal shelf provides room for several desiccant bags that will soak up the humidity from inside the chamber. While there is no active heating, this should very much help keep previously dried spools from getting wet. That’s often a problem, as most operators tend to leave spools mounted on the AMS Lite after printing.

As you might imagine, there are quite a few parts to print and assemble, and there are video instructions on how to proceed. Supergrapher recommends printing all parts in PLA, except for the clips that should be printed in PETG.

If you have an AMS Lite and work in a humid region, you might consider printing this useful accessory.

Via Makerworld