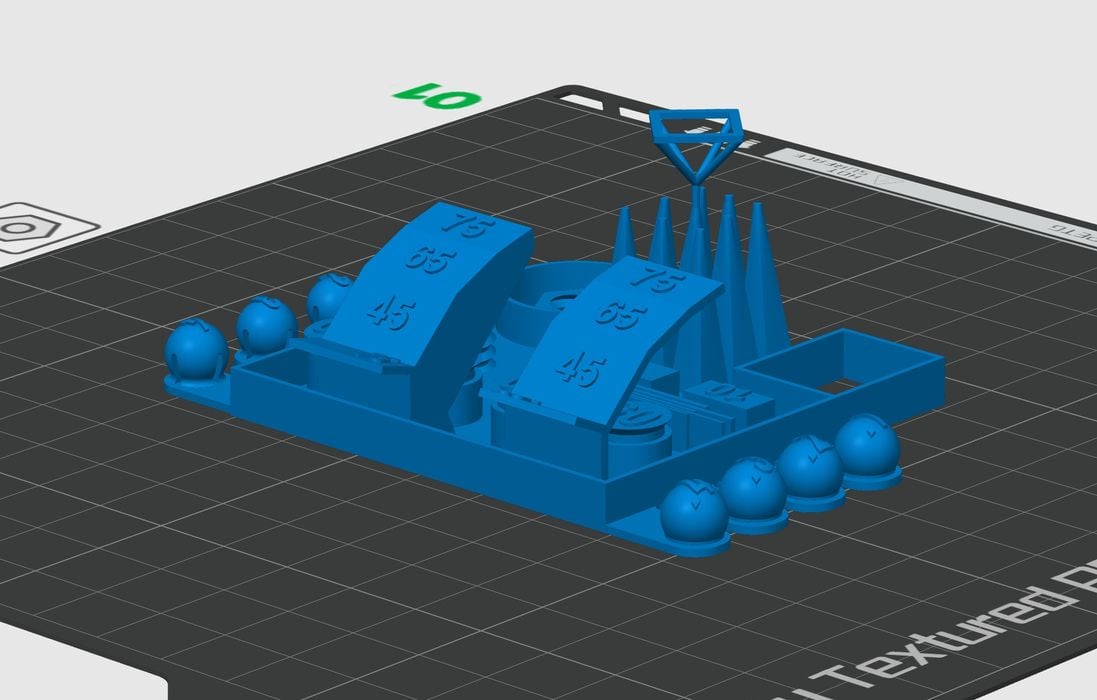

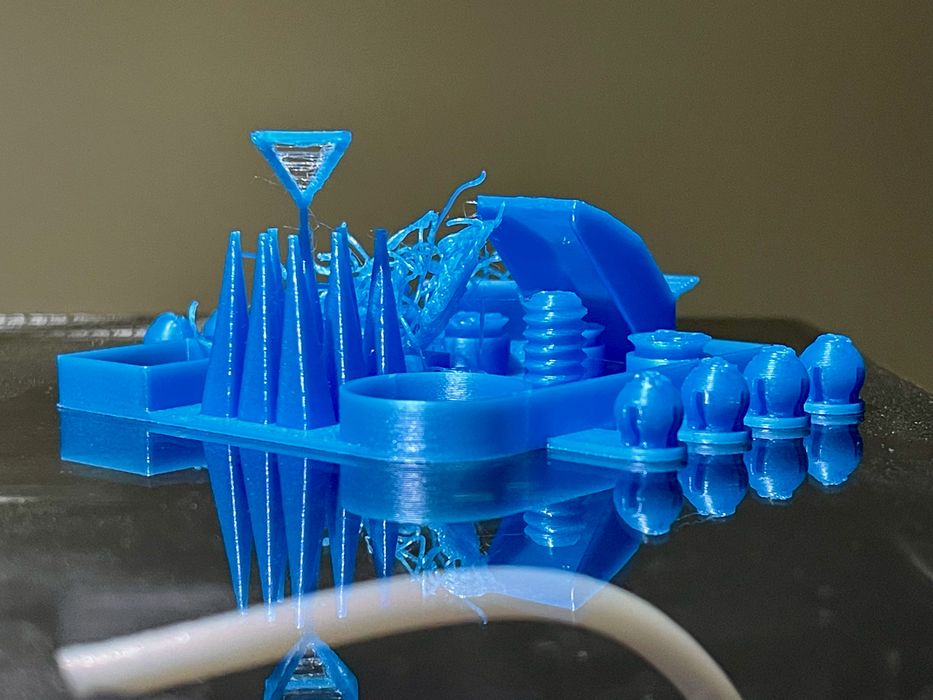

This week’s selection is the The Great Calibrator V3 by mechanical engineer Claudio Girolami.

These days desktop 3D printers are common, and many are available at terrific price points. What’s the differentiation between them? Usually it’s the quality of the prints received from the device.

That quality is a product of the machine’s capabilities and finely tuned print parameters. The machine you buy, but how do you get those parameters? This is best done for each new filament, as every material will have different characteristics.

Increasingly 3D printer manufacturers provide pre-made print profiles that include what they consider to be optimal parameters. If there are no profiles, the operator is on their own to determine the best parameters, usually by trial and error.

Those tests are done with calibration objects, designed to highlight particular printing features. If the calibration print succeeds, then it’s very likely subsequent prints will also succeed.

There are now perhaps hundreds of various calibration objects, some designed to test very specific printer behavior. The ubiquitous #3DBenchy is often used as a test, and it’s pretty good. But it doesn’t always reveal everything when printed.

That has led to the development of more advanced “one test for everything” calibration 3D models, and one of them is The Great Calibrator.

Girolami has been developing this 3D model for some time, and now it’s recently been released as version 3. On the rather long Makerworld description page, Girolami presents a series of various failure modes that can help 3D printer operators learn what went wrong and how to adjust settings to compensate.

If you’re calibrating a new machine or material, you might give The Great Calibrator a try.

Via Makerworld