This week’s selection is the BentoBox v2.0 Carbon Filter by Printables contributor thrutheframe.

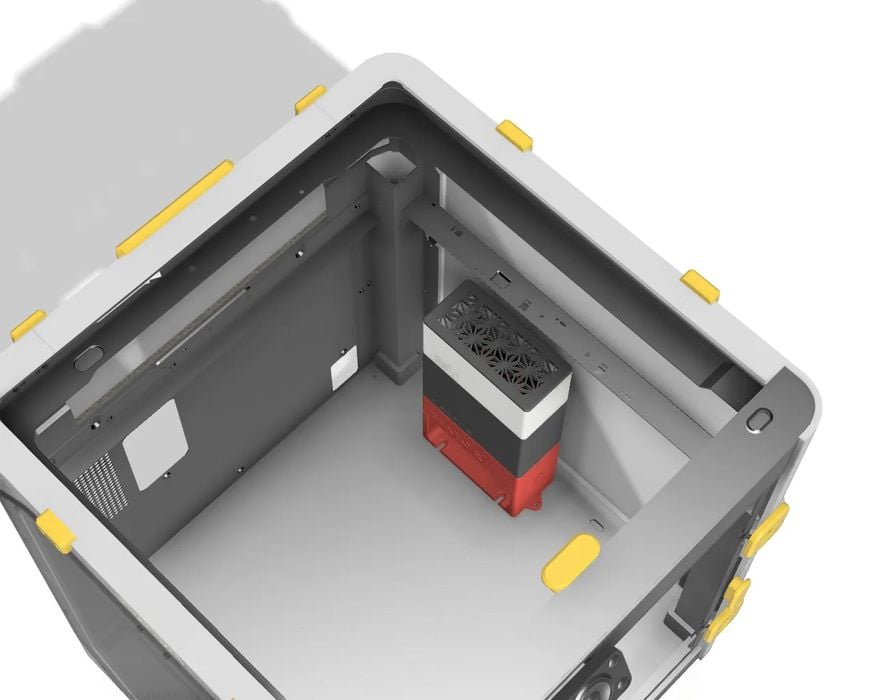

This design is exactly what it says: an internal air scrubber, specifically designed for enclosed Bambu Lab 3D printers, as well as some other enclosed 3D printer models.

Why air scrubbing? When you 3D print certain materials, (ABS, cough), they tend to emit strong odors. What’s happening is the high temperature at the hot end causes vaporization of some of the material. This generates VOCs (volatile organic compounds) and nanoparticles that fill the air around the hot end. These are not healthy and should be removed in some manner.

There are a couple of ways of doing this. First, the most enclosed Bambu Lab equipment has an internal filtration system that can remove some of the contaminants, but it’s not particularly big and can be overwhelmed by emissions from pathological materials.

Another approach is to properly ventilate the workroom where the printer is located. Finally, it’s also possible to purchase a fume extraction system and connect it to the 3D printer to absorb toxic emissions.

The BentoBox v2.0 is an alternative to all of the above. It’s a large air scrubber that sits inside the build chamber where it can directly capture emissions before they can get very far.

This is a bit of a project, as there are several parts to print, as well as a number of non-printed components and consumables that all must be assembled. To guide you through that process, “frame” provides a very detailed twelve page manual.

The structure of the BentoBox v2.0 is vertical: air is pulled from the top, and an opening at the bottom accepts dirty air from the build chamber. The air flows through the middle of the BentoBox v2.0, passing through the HEPA filter and activated carbon.

Non-printed components include fans, brass inserts, M3 bolts, magnets, HEPA filter and acid-free activated carbon, all easily obtainable locally or online at low cost.

The printable components are provided in a large 3MF file that comprises five build plates worth of parts. It’s all set up for printing, although you may have to tweak the settings for your specific 3D printer and material.

The biggest challenge of this project is likely supplying power to the fans. They require a 24V supply, which can be obtained from the 3D printer directly, or by borrowing power from a fan line. It’s also possible to just plug them into an external 24V power supply, which might be the easiest approach.

There are several pieces of advice to builders in the manual about fans. It appears that the position of the fans is critical, as the filtration will be far more efficient if air is pulled through the filtration components than pushed. In addition, certain fans are recommended.

Another critical item is that the carbon consumable must be acid-free. If not it can “mess up the printer in no time.”

The BentoBox v2.0 can easily serve a wide range of 3D printers. One installation even had it set up inside a small tent containing a resin 3D printer. That could be an ideal situation for resin 3D printer operators that aren’t easily able to ventilate their workspace.

The BentoBox v2.0 is available for free download, but it’s also possible to buy them with all required components from several online sources for about US$50.

Via Printables