This week’s selection is the Alyx bicycle by FUTUREWAVE.

The Belgian design firm has produce a series of quite radical takes on a variety of subjects, and the Alyx bike is one of them. The bike frame is made from 3D printed aluminum metal, and leverages the technology in ways that haven’t really been done previously.

Their goal seems is to balance the ability to join parts together with aesthetics. Typical bike frames all resemble a collection of pipes connected by joints. This makes it easier to produce and assemble, but comes with a standard “look”. FUTUREWAVE wanted to change that. They explain:

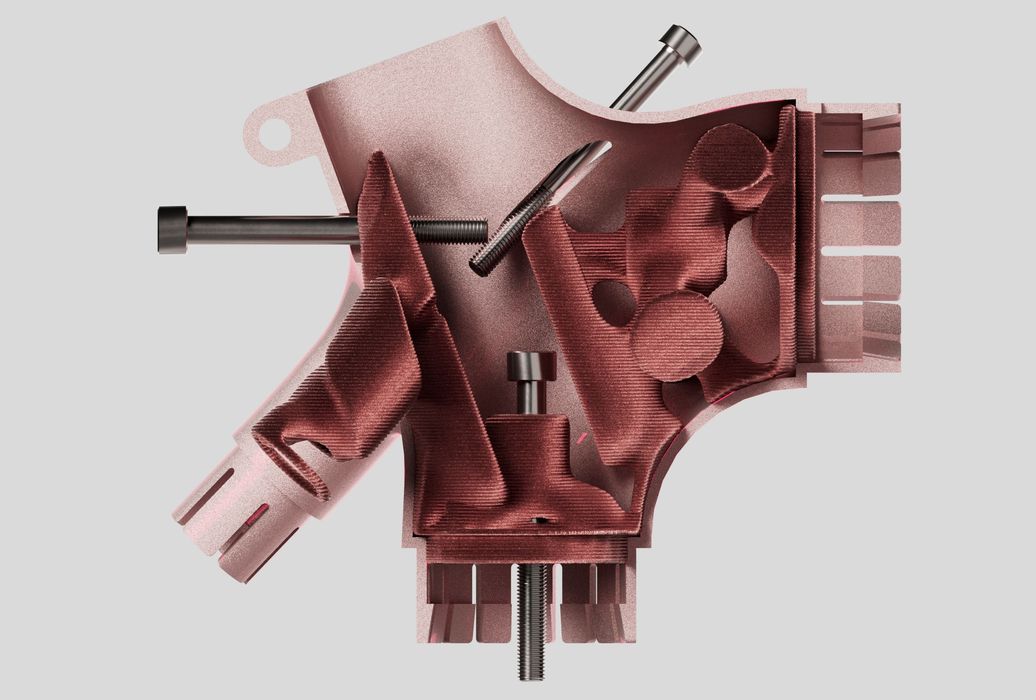

“Replacing parts can be complex due to their lack of standardization. To overcome these obstacles, we had the idea of creating standardized parts for bicycle frames. However, achieving aesthetically pleasing junctions with standardized parts is difficult. This is where metal 3D printing additive manufacturing technology comes in. This technology allows us to design parts with precise and elegant junctions while maintaining standardization.”

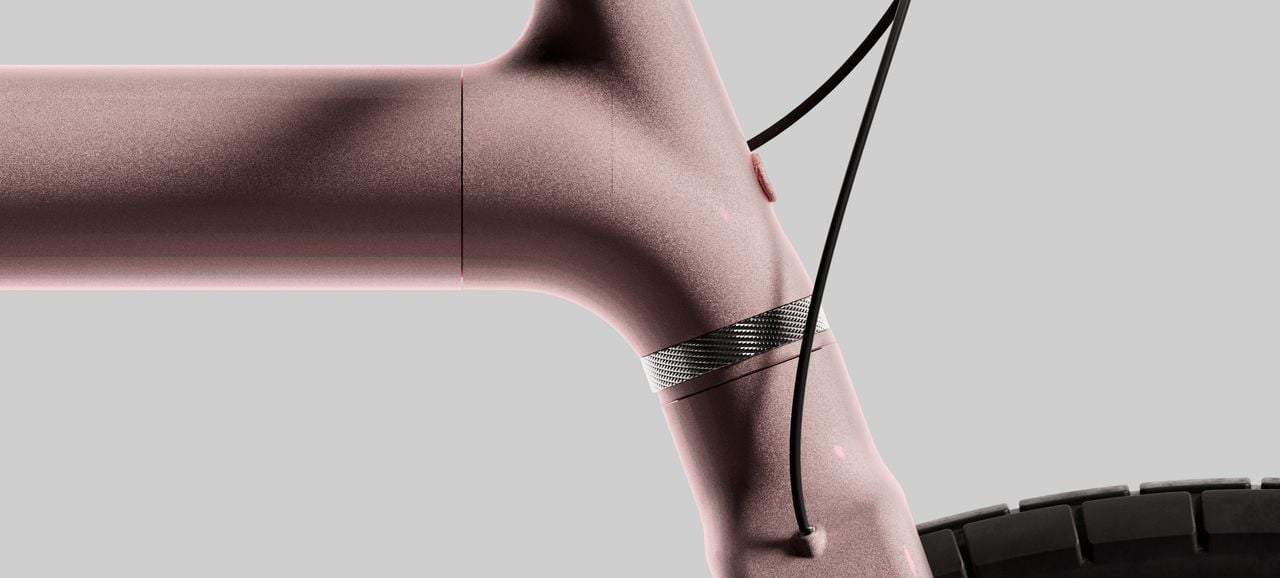

This is quite evident in the design if you look carefully at the joints. You can see they don’t really look at all like standard bike joints, and there are very smooth and attractive curves involved. FUTUREWAVE said that “each piece fits perfectly into another”.

This approach can even be used to re-size the bike to fit the wearer, simply by replacing a few parts. This is because the joints were designed in a way that accommodates different pieces.

Underneath the joints you can see above the complex structure made possible by 3D printing. This adds significant strength to the part, while maintaining a light weight — and not compromising the exterior appearance.

The approach also minimizes welding efforts required to join parts together.

This is quite an interesting design that demonstrates how product creators can leverage 3D printing and its ability to build structures without constraints.

Via FUTUREWAVE