Could furniture be the next big application for 3D printing?

While 3D printing technology has long been used for prototyping, there are several key production application areas that power 3D printing business these days, including aerospace, dental, automotive and healthcare. These industries have used 3D printing for quite a few years, and it’s because they each had qualities that matched the technology.

Those characteristics would be:

- Availability of required materials

- Need for complex geometry parts, often to reduce weight

- Existing expectation of high part costs

- Ability to certify parts with regulatory agencies

- Consistent part production even at scale

Lots of industries have those characteristics, but few have the “high cost” factor. That’s perhaps the biggest reason 3D printing has been adopted by those industries. We all know aerospace parts cost a lot, so 3D printing them at similar costs doesn’t make as much difference.

This has been the state of affairs for some time now, and I’ve been wondering where the next big application area might emerge for the technology.

While there’s burgeoning interest in the construction 3D printing sector, it is still in the early stages. But another application area that seems to be increasingly popping up on my radar is furniture.

3D printed furniture is not a new thing; it’s been attempted for many years after the emergence of larger-format 3D printers. The problem has been the cost and time to produce furniture on this type of equipment. That’s the same issue faced by many other industries that have not been able to adopt the technology: it just doesn’t make financial sense.

Perhaps things are changing.

In recent years we’ve seen a couple of technological developments that just might change the equation for furniture production.

One is the lowered cost of larger-format 3D printers. There was a time when you’d pay US$50,000 or more for a basic, but large format FFF device. Those days are starting to fade, as new equipment is slowly emerging: Elegoo’s Giga device will be available for around US$2000, far less expensive than other large format machines. It’s very likely their competitors will follow with their own large format FFF devices.

Another change is the shift to pellet 3D printing. The first large format FFF devices used filament as the material. However, common filaments were designed for smaller devices and came in tiny formats: 1.75mm diameters. This meant that large format FFF devices would require lengthy periods to print even moderately-sized objects.

In the production business, time is money: a machine that prints 24 hours a day would make more money if it could complete three jobs in those hours rather than just one. The cost of running the machine has to be bundled into the cost of the products produced, so faster printing means less expensive products.

Desktop 3D printers have undergone a revolution in the past year with the introduction of very high speed devices, in some cases able to print at speeds up to 10X of the earlier devices. This same speed-up tech can now be ported to larger format FFF 3D printers, and that should dramatically cut down on the cost to produce parts.

The result of these factors could trigger increased interest in furniture 3D printing. A recent story from BigRep, a manufacturer of large format 3D printers, highlighted one of their customers that produces furniture on the equipment.

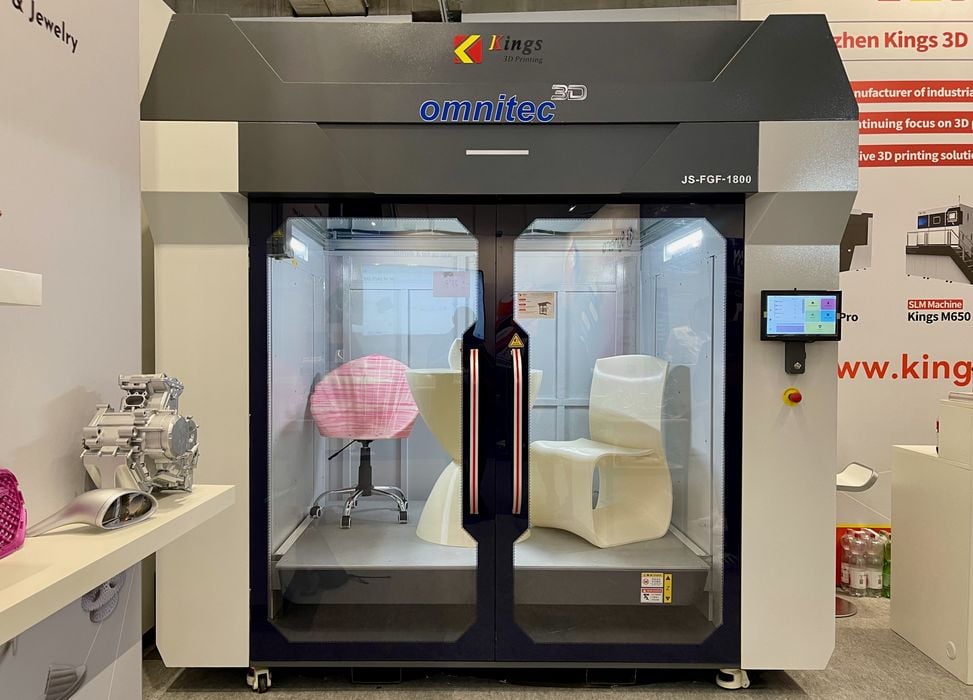

Recent trade shows frequently showcase furniture being produced by a variety of equipment, ranging from FFF to resin to robotic solutions.

I’ve heard several instances of artists taking up 3D print technology to enable low volume production of custom-designed furniture. However, these products still carry premium costs and are not really scalable to mass production.

But that didn’t stop the progress of 3D printing in aerospace or healthcare, where many parts are produced in lower volumes or custom made.

It may be that in the next few years we see an increasing number of 3D printed furniture operations appear. You may be sitting in a 3D printed chair a few years from today.

Via BigRep