LEAP 71 performed a monumental real-life validation of their computational engineering approach with a rocket engine hot fire.

The Dubai-based company has been developing advanced 3D design software that can generate highly complex parts using what’s called “computational engineering”. The idea is to create a system focused on a specific application domain that accepts descriptive inputs. The system would then generate the entire part design at a voxel level.

You can read a thorough introduction to the concepts of Computational Engineering here, written by LEAP 71’s Lin Kayser. If that piques your interest, LEAP 71 has open-sourced the kernel of their system as the PicoGK framework, and you can even try it yourself. Read more about PicoGK here.

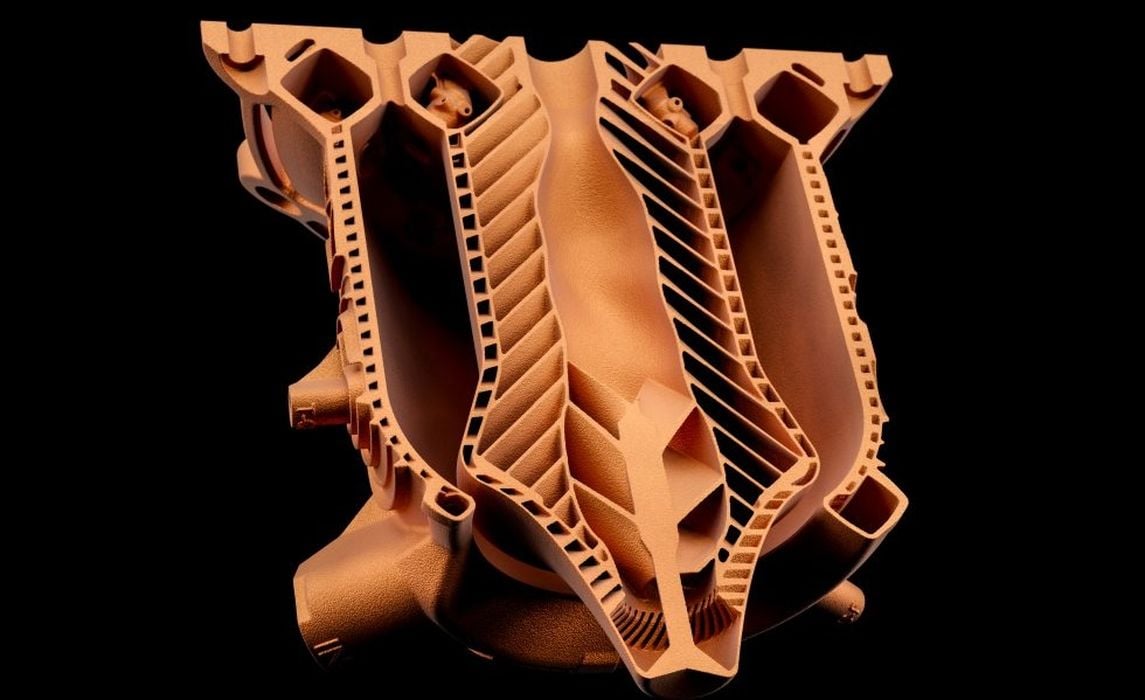

What’s the milestone? For several months now, LEAP 71 has been working with partners to use Computational Engineering to design an entire rocket engine. Not the parts of the engine, but the entire engine, less input pipes and mounting.

Rocket engines are notoriously complex devices because they undergo the most severe mechanical and thermal stresses human-made machines experience, and failures are, well, interesting.

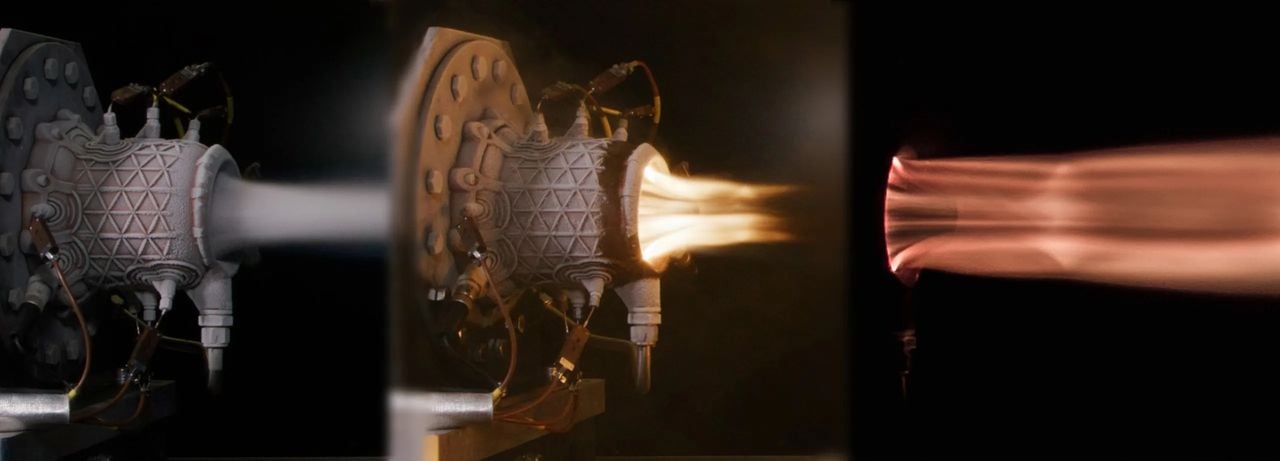

The particular project undertaken here was not only to design and 3D print the entire rocket engine, but also one with a highly unusual design. Instead of the traditional “bell” structure at the bottom of the rocket engine, the aerospike design has a small cone. The fuel and oxidizer ignite on the outside and push inwards on the cone to produce thrust.

Aerospike designs should be more efficient because the size of their “virtual bell” varies according to external air pressure. This means the aerospike engine would be at optimum efficiency from sea level all the way to orbit, unlike traditional rockets.

This all sounds good, but does it work?

LEAP 71 and its partners were able to complete the design, as shown here. They used the latest version of their Computational Engineering engine, Noyron. The inner structure of the rocket engine is quite complex because of the need for high-speed cooling channels to keep the engine from melting itself.

This past week, the company was able to perform a “hot fire” test of the 3D-printed aerospike engine, and it worked perfectly on the first attempt. In fact, they performed four successful tests, with no failures.

LEAP 71 CEO Josefine Lissner explained:

“We were able to extend Noyron’s physics to deal with the unique complexity of this engine type. The spike is cooled by intricate cooling channels flooded by cryogenic oxygen, whereas the outside of the chamber is cooled by the kerosene fuel. I am very encouraged by the results of this test, as virtually everything on the engine was novel and untested. It’s a great validation of our physics-driven approach to computational AI.”

Why is this important? Because they now have a computational engine capable of producing aerospike engine designs on demand. With tuning, they should be able to rather quickly design larger and more capable aerospike designs.

That’s quite astounding because the challenges of developing these engines have baffled engineers for decades. Now it is — almost — automatic.

Via LEAP 71