Charles R. Goulding and Leah Nabangi consider how Europe’s leading 3D printing companies could help bridge the productivity gap with the US and drive economic growth across the continent.

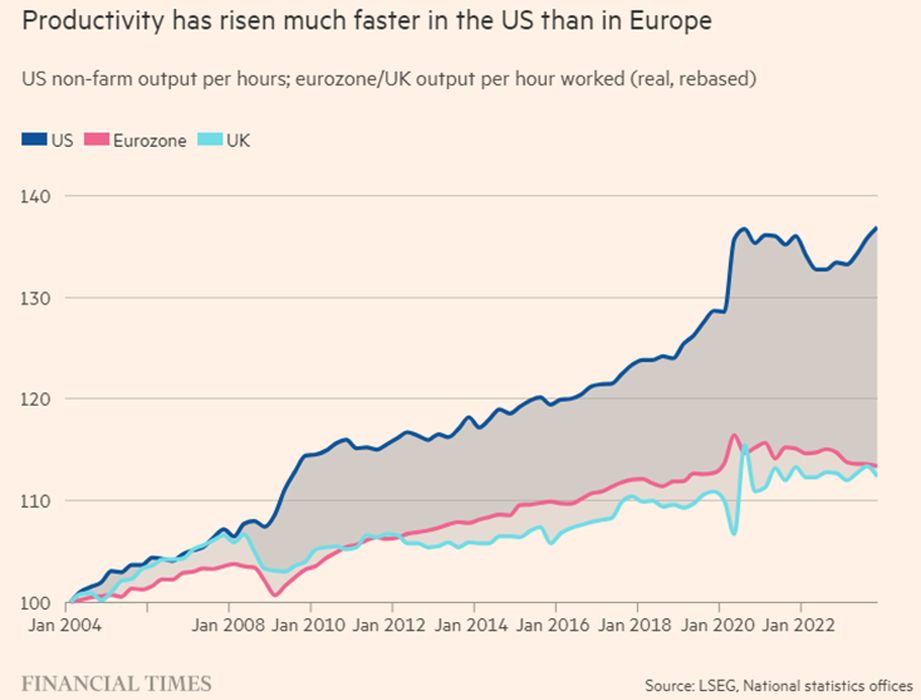

Leading European policy experts are becoming alarmed about the declining European productivity particularly when compared to the US. As the below chart illustrates European productivity has measurably declined compared to US productivity. The UK has had a major decline in productivity and we have previously written

In our view, some of the key technologies where the US provides productivity leadership are AI, digitization and Industry 4.0, including automation.

European policy experts trying to close the gap may want to look at some of Europe’s best-of-breed companies that are benefiting from 3D printing technology.

United Kingdom

Here leading companies utilizing 3D printing are Renishaw, BAE, and Rolls-Royce. Improving the UK’s productivity will have a major impact on improving overall productivity.

Germany

3D printing leaders include Siemens and Adidas, Rheinmetall AG, BASF, and the Fraunhofer Institute. Germany has traditionally been the leader of European productivity and must return to that status if overall Europe is going to improve.

France

France is one of the world’s leading design centers and leading designers employing 3D printing include LVMH and their large Tiffany business unit. Saint-Gobain, the large multinational glass, construction, and high-performance materials company is headquartered near Paris.

Denmark

Denmark provides world leadership in 3D printing for toys with LEGO, pumps with Danfoss and wind turbines.

Sweden

Sweden is the home to Cell Link the world’s leading 3D printing company for bioprinting.

Pan-European

Multi-country major Pan-European 3D printing users include the passenger rail industry and Airbus the major aircraft manufacturer that is currently leapfrogging Boeing.

The Research and Development Tax Credit

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

In business when attempting to catch up one of the first steps is to determine where one has core strengths. Europe has many strengths and studying successful 3D printing users is one avenue to analyze and build from.

Although 3D printing is one of the technologies Europe can optimize to improve production it has to be in the context of overall reform. Mario Draghi, the former ECB governor recently made the following prescient comment to 27 countries’ ministers, “Please do something, you choose what, but you can’t spend more time basically saying no to everything”.