Researchers have developed an entirely different form of 3D printing they call “chip-based”.

There’s a few things to know before you can understand their chip-based concept.

Resin 3D printing has been around for many years: a liquid photopolymer is selectively solidified by exposure to energy, typically UV light. These systems typically involve motion systems that build objects layer by layer.

There’s another promising approach that I’ve been keeping my eye on: volumetric 3D printing. In this concept we’re still using resin, but the motion system differs. Instead of layer by layer, the system projects light patterns all at once into the clear vat of material. Often this is done with a transparent cylinder of resin that rotates in front of a projector.

The volumetric approach is as much as 100X faster to print objects because they appear all at once instead of layer by layer. There’s only one volumetric commercial option on the market at this time, from Xolo.

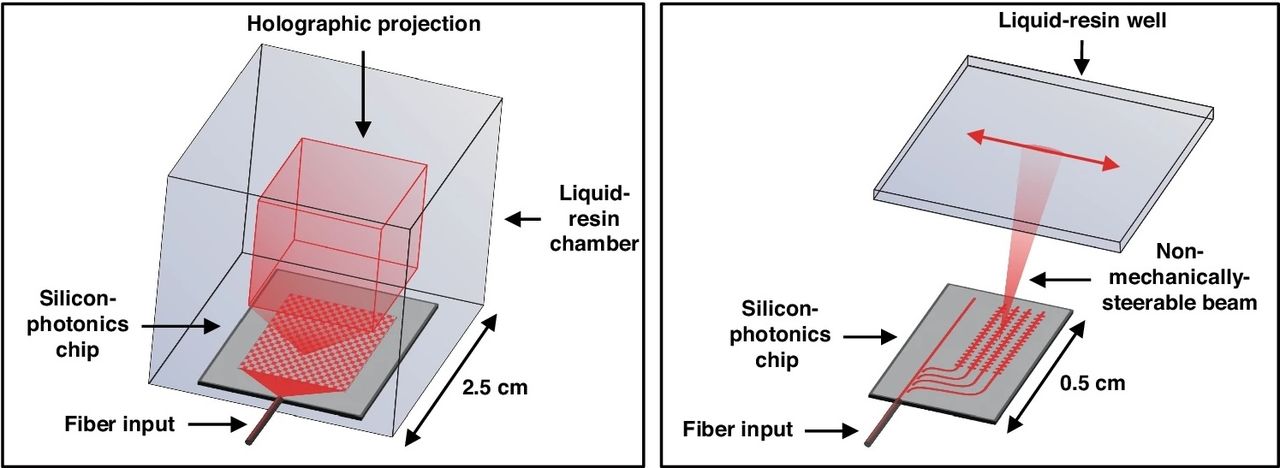

Understanding all that leads us to the chip-based concept. The researchers were concerned with all the hardware required to implement volumetric 3D printing: you need a rotating vat, projectors and other hardware to make it work. They write:

“However, these methods still remain reliant on bulky and intricate mechanical systems, such as rotating stages and multi-angle illumination frameworks. Thus, there remains a growing need for a new compact, portable, and low-cost 3D-printing technology.”

Their idea is to deliver energy to the resin vat using a hologram. A hologram is a three dimensional image in 3D space. Imagine this light landing at all the correct spots in a vat of resin to simultaneously cure the whole object at once.

They explain:

“We combine the fields of silicon photonics and photochemistry to propose the first chip-based 3D printer. The proposed system consists of only a single millimeter-scale photonic chip without any moving parts that emits reconfigurable visible-light holograms up into a simple stationary resin well to enable non-mechanical 3D printing. It presents a highly-compact, portable, and low-cost solution for the next generation of 3D printers.”

Hold on, let’s review what they just wrote:

- This is a 3D printer that produces the object all at once

- It has NO MOVING PARTS!

If this sounds like science fiction — and it does — it’s actually factual. The researchers built a device to implement the chip-based concept.

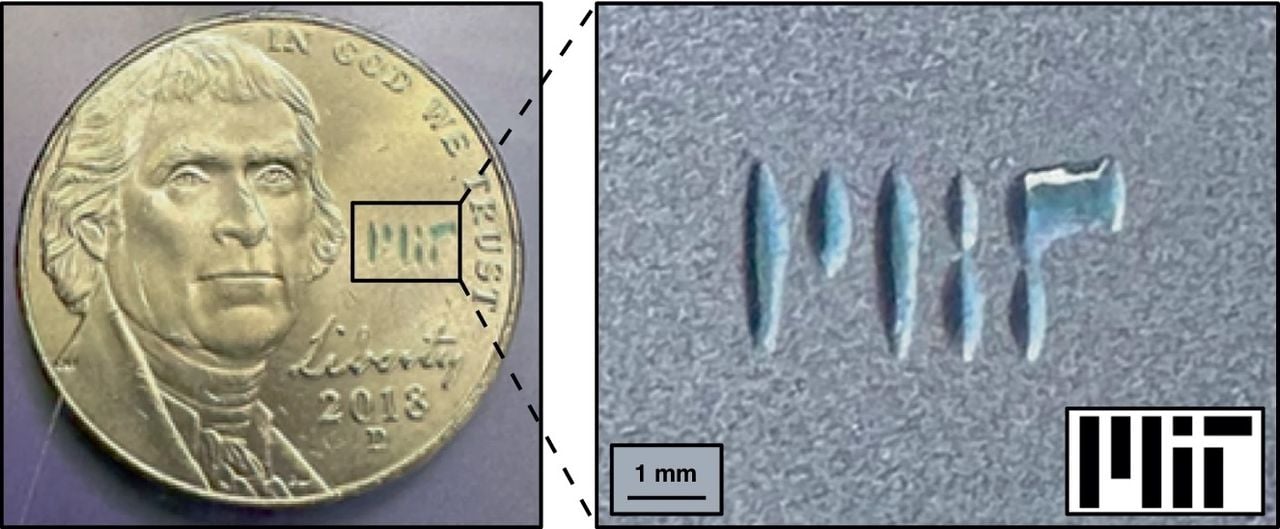

To be clear, their demonstration was not even close to being a product one could purchase. It was a demonstration of the ability to cure first a single voxel in resin, and later groups of voxels. The experiments allowed them to determine curing rates and other aspects of the concept.

How does it work? They explain:

“The proposed chip projects visible-light 3D holograms in the shape of a desired object upwards into the resin well to induce selective solidification of the resin, resulting in a volumetric 3D print.”

They say that by demonstrating the concept it could be possible to build 3D printers that have no moving parts. There would be a resin tank and a photonic chip (or several) to generate holograms of the desired 3D model.

There was challenge, however. Commercial 3D printer resins tend to be cured at short wavelengths, typically 405nm. However, the commercial silicon photonic chips they used in the experiment generate longer waves, even infrared. To enable the experiment to proceed they had to make use of resin that polymerized at higher wavelengths.

This could be one of the biggest breakthroughs in 3D print technology for decades, if it can be scaled up and commercialized. This paper describes only research, but you can bet that there will be multiple parties investigating the technology with the intent of commercialization.

Via Nature