Carbon announced a new component to their AO Suite: AO Stack.

The AO suite is Carbon’s software platform for operating and enhancing print operations on their equipment.

The Suite includes a number of tools, including basic job preparation and dispatch, script builder and more.

The latest addition to the suite is “AO Stack”, which is described by Carbon:

“AO Stack is another software tool designed to increase printing capabilities, allowing dental labs to print multiple builds worth of DPR10 models in one print run without supervision.

AO Stack allows Carbon users to produce up to three times more models in a single unattended print cycle, perfect for the last print of the day. This underscores Carbon’s commitment to pushing the boundaries of dental lab technology and continuing the innovation within the Automatic Operation suite of solutions launched earlier this year.”

Carbon elusively does not actually describe how AO Stack accomplishes, this, but one can surmise from the product’s name what’s actually happening.

My suspicion is that AO Stack examines print jobs and “stacks” them together. This is likely done through an ingenious algorithm that might thread supports between models to create new higher regions where models can be placed.

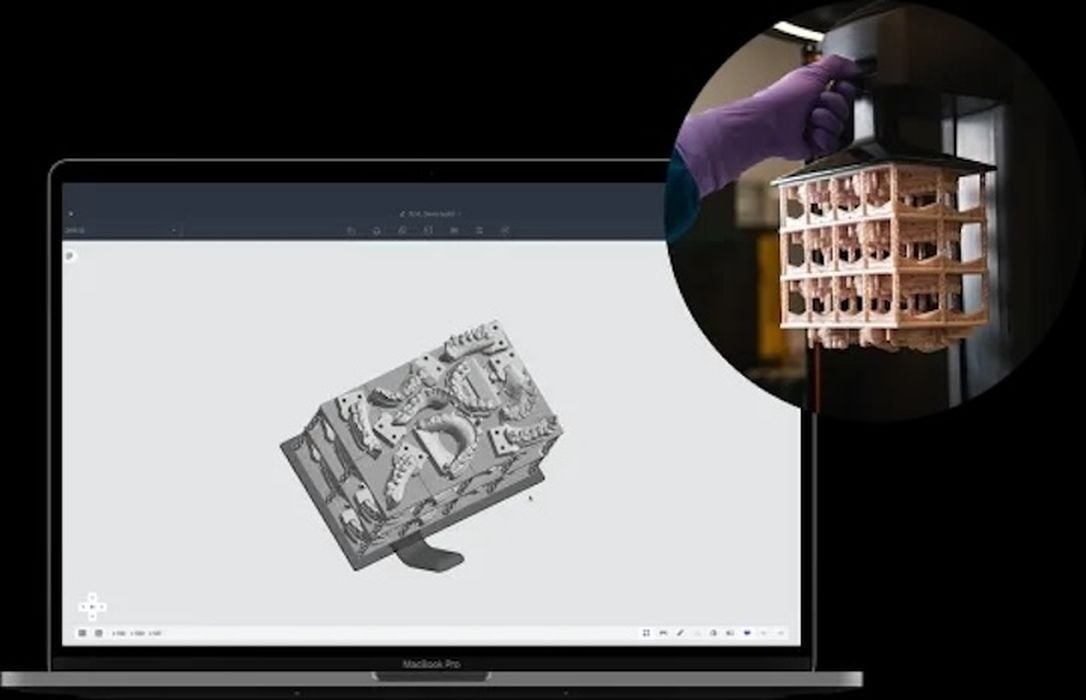

If you look at the image at top from Carbon, you can see what’s going on: the parts are all there in three layers, but there is a considerable amount of support material that effectively creates two additional build planes.

This could overcome one of the primary limitations of resin 3D printing: you can normally have only one “layer” of models on the print plate. This is quite unlike many powder-based 3D printing processes, where the entire build volume can be occupied with parts. Such systems often have software that can “Tetris” the maximum number of parts into the build volume.

It seems that AO Stack breaks this barrier and provides an easy means for Carbon operators to take advantage of this concept.

By stacking more parts into a job, efficiency can be increased. A large portion of the cost of a 3D print is actually the labor required to handle prints. While Carbon has provided quite a bit of automation, they can further increase efficiency by reducing the number of jobs required to produce the parts.

There’s one catch, however: it turns out that AO Stack is available only on the company’s M2 and M3 machines. Operators of the M1 and L1 devices can’t make use of AO Stack, at least not yet.

Carbon said access to AO Stack is automatically included in operators’ subscription, likely making it an instant hit with M2 and M3 operators.

Via Carbon