There could soon be some interesting advancements in the 3DCP field.

3DCP, or “3D Construction Printing”, is a relatively new type of 3D printing. The idea is similar to desktop 3D printing in that a computer controlled gantry moves around a toolhead to deposit material. In this case we have concrete instead of polymer material.

This technology has been used successfully to build concrete walls and foundations for an increasing number of projects around the world, and there are several manufacturers of 3DCP equipment. This equipment is typically operated by regional construction companies to speed up the concrete portions of their projects.

At this point it’s still very, very early in the technology maturation process, and while adoption of the technology has been positive, it’s still a rarity in the construction industry.

My suspicion is that the limited adoption thus far is due to a combination of lack of awareness among builders and still-evolving technology. Most of the innovations in 3DCP seem to be related to materials, rather than the extrusion technology itself.

That could change, however, with an upcoming announcement from BuildEra 3D.

The California company is headed by founder and CEO Jiang Xufeng, who recently posted a message about his company’s plans for improving 3DCP technology.

Unlike many 3DCP operations, he’s open about the current issues with 3DCP technology. While it’s often said that buildings “can be printed in a day”, that’s just not true. Xufeng points out that these claims don’t account for machine setup and takedown, as well as other factors that real projects must deal with.

Among his issues are:

- Removal of material hopper after printing

- Cleaning the equipment after printing

- Recalibration challenges

These seem like real problems that would be encountered when using 3DCP equipment, and project workers must encounter them on every job site.

But what should be done about them? Xufeng writes:

“This time, with 10+ years expertise dedicated with 3DCP and our new innovation, we will bring the industry a new solution for MATERIAL EXTRUSION to a brand new level: both for mortar & concrete, 50% less for washing time, 80% less for installation time and re-calibrationless for the TCP/nozzle.”

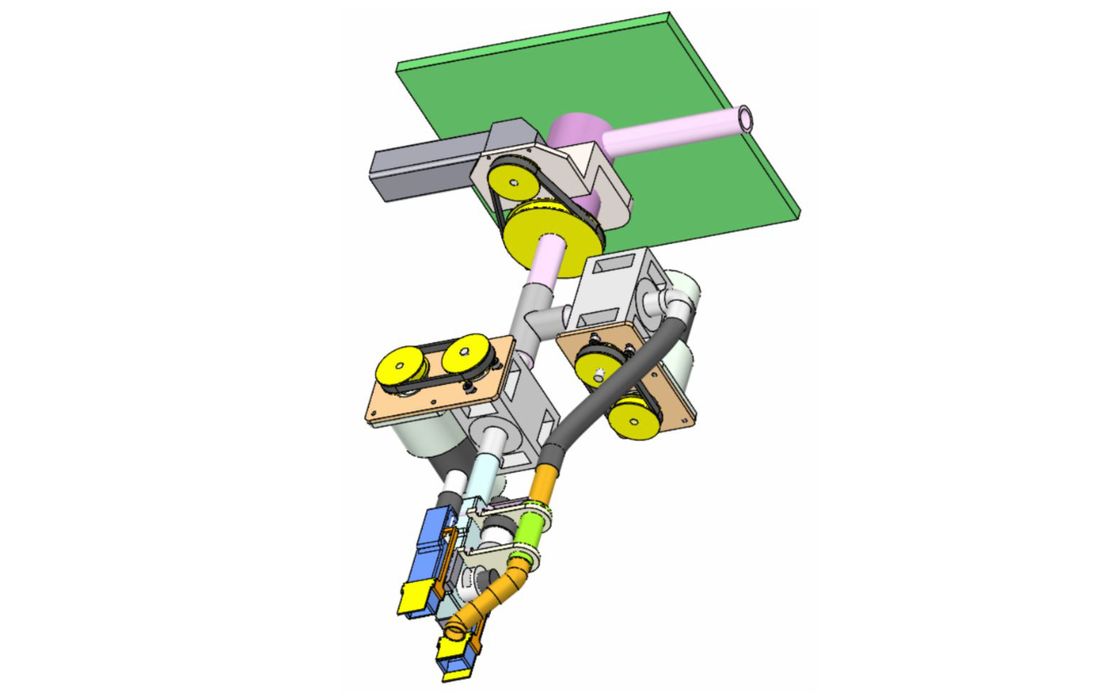

It seems that BuildEra 3D will unveil a new design for a concrete extruder in the near future. Xufeng posted a number of images of what could be the new design, shown above.

The design of the new toolhead seems complex, and different from other extrusion systems. It’s not exactly clear how the proposed features are implemented in the design because BuildEra 3D hasn’t explained them yet.

What we’re seeing here is the beginnings of a technological war in 3DCP, where equipment manufacturers will continually improve their systems to gain an advantage. In the polymer and metal 3D print universes, similar patterns emerged and over the course of years we ended up with extraordinarily capable devices.

The same may come to pass in 3DCP.

Via BuildEra 3D and LinkedIn