A research paper explores a new formulation for silicone that may affect 3D printing.

Silicone is a very popular material in industry, but far less so in 3D printing. There are relatively few 3D printers that offer the ability to print silicone, and usually there are some constraints when doing so.

Most of those constraints are driven by the fact that silicone is a slow curing material. This means that during the printing process, the material remains quite soft. That precludes the printing of certain more complex geometries, such as overhangs or thinner walls, which would collapse.

This could change with the introduction of a new two-part silicone formulation developed by the researchers. When mixed, the “fast cure” ink cures far faster.

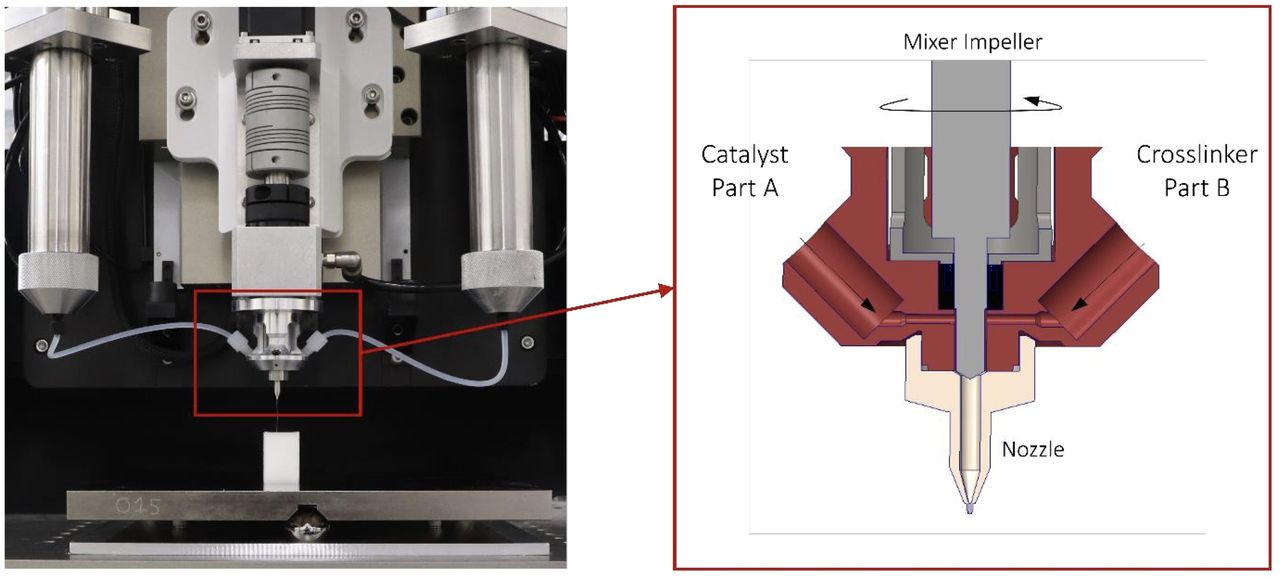

How does it work? They added a catalyst in the part A material, and a crosslinker in Part B. When mixed, these two “rapidly rigidize”, forming a solid structure.

The result is a silicone material that can actually print overhangs up to 35 degrees. It’s also possible to tall 3D print objects with aspect ratios higher than 3.0 — quite different than the mostly flat, 2.5D-style silicone objects typically seen on 3D printers today.

Amazingly, the researchers say that these results were obtained without any need for extra processing steps, such as post-curing, nor the use of any support structures or other mechanisms: it just prints properly.

At the top you can see the apparatus used to test the fast cure silicone material, and it doesn’t look terribly different from any of today’s 3D printers. I expect it would be relatively straightforward to implement this technology commercially.

In fact, the material might even be directly used by some existing silicone 3D printers that happen to use a two-part extrusion system.

One intriguing possibility is Filament 2’s silicone filament system. You can read more about it here, but in short, they put the two parts inside a filament-sized tube, separated by a membrane. The tube is fed into any standard FFF 3D printer with a simple nozzle modification. It’s very possible to 3D print silicone using their system.

However, if they made use of the new fast-cure ink, it might then be possible for almost any FFF desktop 3D printer to print highly complex silicone objects.

Via Wiley