Charles R. Goulding and Preeti Sulibhavi focus on how 3D printed ultra-thin glass is transforming energy-efficient building design, cutting costs, and unlocking R&D tax incentives for innovators.

The quest for energy-efficient buildings has led to significant advancements in building materials and construction techniques. One promising development is the use of 3D printed ultra-thin glass for windows, which aims to enhance insulation, thereby keeping buildings warmer in winter and cooler in summer. This innovation addresses longstanding issues of energy inefficiency and high utility bills associated with traditional glass windows.

Architects, engineers, retrofitters and glass specifiers can earn large tax incentives for providing energy-efficient glass in qualifying buildings.

The Challenge of Energy Inefficiency in Traditional Windows

Windows have been a fundamental component of residential architecture for centuries, providing natural light and ventilation. However, traditional windows are often the weakest link in a home’s thermal envelope. Standard double-pane windows can lose up to 20 times more energy per square foot compared to insulated walls, leading to increased heating and cooling costs. This energy loss not only impacts homeowners financially but also contributes to higher carbon emissions.

Evolution of Glass in Residential Construction

The use of glass in buildings dates back to ancient Rome, but it became more prevalent during the Industrial Revolution with mass production techniques. Over time, advancements such as double glazing and low-emissivity (low-e) coatings have improved window performance. Despite these improvements, traditional glass windows still pose challenges in terms of weight, thickness, and energy efficiency.

Ultra-Thin Glass: A Modern Solution

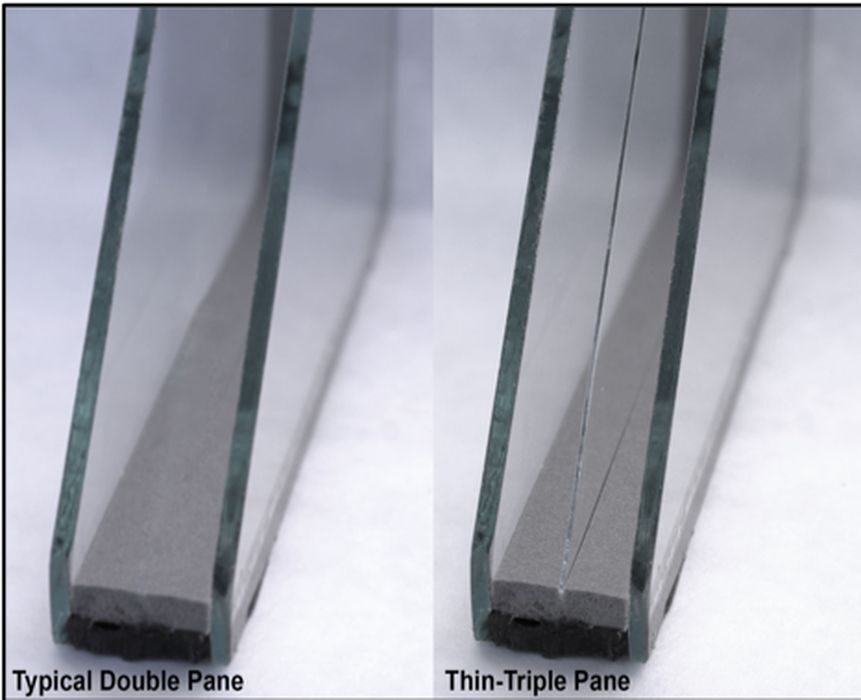

Ultra-thin glass, inspired by technologies developed for smartphone screens, offers a promising alternative. Companies like Corning have developed glass that is thinner than a credit card yet strong enough to be layered between thicker panes to create highly efficient windows. These triple- and quad-pane windows are lighter, more durable, and provide superior insulation compared to traditional double-pane windows. Additionally, they can be customized to withstand severe weather conditions, making them suitable for various climates.

Lawrence Berkeley National Laboratory’s Contributions

Berkeley Lab has a longstanding history of research in window technologies aimed at improving energy efficiency. One notable innovation is the development of the “thin-triple” window concept, which incorporates a thin glass center layer to enhance insulation without requiring significant modifications to existing window frames. This design offers a cost-effective solution for upgrading the energy performance of residential windows

Additionally, Berkeley Lab has explored dynamic window coatings that can selectively control visible light and near-infrared radiation, further contributing to energy savings and occupant comfort. While these advancements primarily focus on material science and coatings, the integration of 3D printing techniques in developing and testing these technologies is an area of ongoing research.

3D Printing Innovations in Glass Manufacturing

The integration of 3D printing technology into glass manufacturing is opening new possibilities for creating complex and efficient window designs. Several companies and research institutions are at the forefront of this innovation:

- Lawrence Livermore National Laboratory (LLNL) and University of California, Berkeley: Researchers have demonstrated the ability to 3D print microscopic objects in silica glass using a laser-based Volumetric Additive Manufacturing (VAM) approach. This technique enables the production of delicate, layer-less optics in seconds or minutes, paving the way for advanced glass components in various applications.

- Glas Trösch and Corning Incorporated: In a collaborative effort, these companies have developed a prototype triple insulating glass unit utilizing ultra-thin glass. This innovation aims to reduce the carbon footprint of architectural glass and enhance energy efficiency in buildings.

- Glaston Corporation: Glaston has introduced Triple TPS® insulating glass units featuring an ultra-thin center glass down to 0.5 mm. This development offers improved insulation properties while reducing the need for robust frame support, contributing to more energy-efficient homes.

- Lucent Optics and Lawrence Berkeley National Laboratory (Berkeley Lab): Lucent Optics collaborated with Berkeley Lab’s FLEXLAB® to evaluate a novel, 3D printed window film designed to reduce cooling loads and glare. This partnership focused on optimizing the film’s design parameters to achieve superior performance in real-world applications.

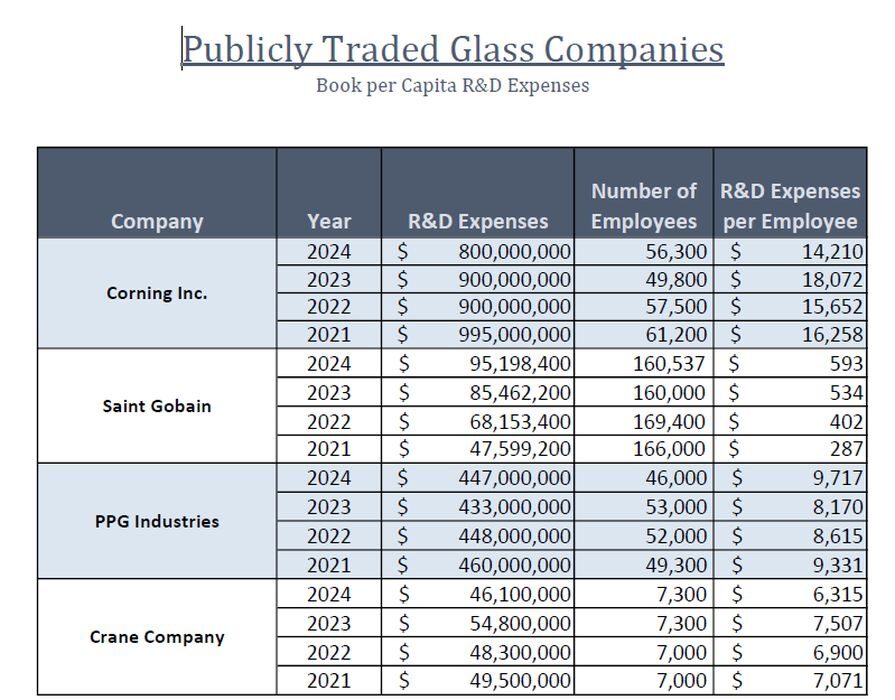

Below is a table that depicts the recent investments in research and development (R&D) that leading glass companies have been making in recent years.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The convergence of ultra-thin glass technology and 3D printing holds significant promise for the future of energy-efficient residential construction. By enhancing the insulation properties of windows and enabling the production of complex, customized designs, these innovations have the potential to reduce energy consumption, lower utility bills, and contribute to a more sustainable built environment. As research and development continue, collaboration among industry leaders, research institutions, and policymakers will be crucial to bringing these advanced technologies from the laboratory to widespread adoption in homes worldwide.