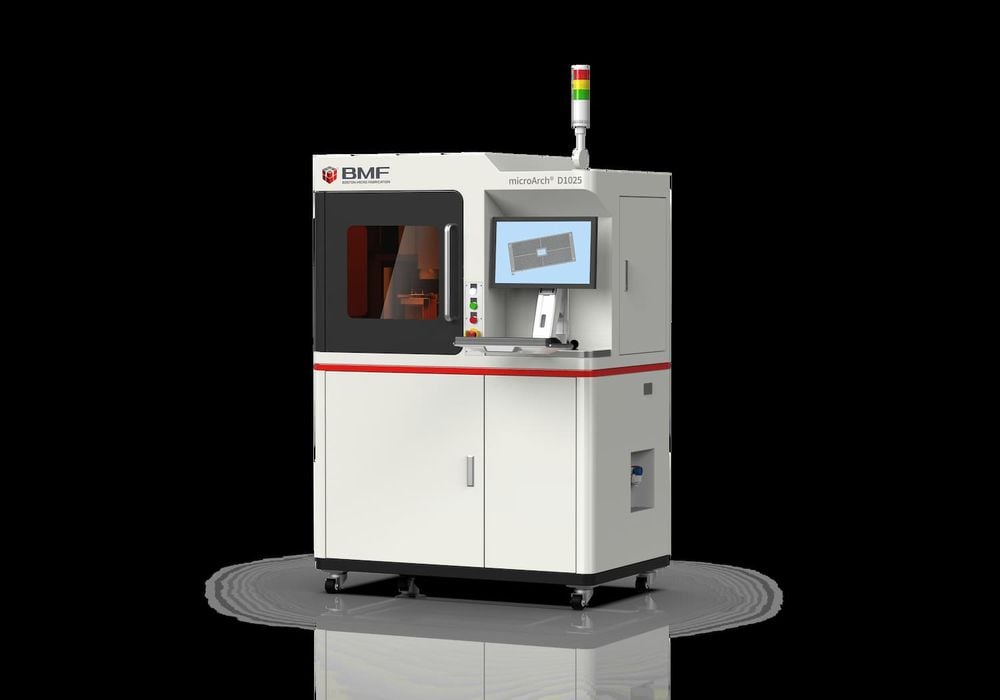

Boston Micro Fabrication introduced something quite unique: a hybrid resolution micro 3D printer.

Their new microArch D1025 device is able to print small, high resolution objects like others in their product line. Some of their devices can print features as small as 0.02mm. However, there’s a big difference with the D1025: it can print in two different resolutions in the same job.

All BMF machines use a photopolymer process they call ”PµSL” (Projection Micro Stereolithography) to selectively solidify a liquid resin. They use a DLMP By configuring the optical system it’s possible to focus the light down to tiny pixels, which represents the resolution of the job.

Typically machines of this type have a fixed optical arrangement, meaning there is only one resolution possible. That’s good if it’s the resolution you require.

But often there is a benefit to change resolutions, sometimes even within the same print job. Some parts may require fine details that demand the higher resolution, while other parts might have coarse features that are more easily produced.

The D1025 can print in either 0.010 or 0.025 mm resolutions. It’s easily possible to print a job in either resolution by selecting it in the slicing software.

BMF explains what’s possible:

“Using a technique that allows for rapid photopolymerization of layers of liquid polymer using a flash of UV light at micro-scale resolution, the 25µm resolution mode can be used for parts in which the features don’t require ultra-high resolution and 10µm mode supports small, complex features to optimize the 3D printing process. Users also have the ability to choose to print a single build in either 25µm or 10µm depending upon the part geometry, providing greater flexibility and efficiency across all applications and industries.”

It’s possible to print with the different resolutions in the same layer, or on different layers of each print job.

It seems that the biggest benefit here might be for BMF customers, who can now acquire one machine that has the capabilities of two different BMF machines. That could be quite a bit more economical.

Via BMF