Charles R. Goulding and Preeti Sulibhavi discover Tampa’s transformation into a tech hub, driven by cutting-edge 3D printing technology revolutionizing its medical and maritime industries.

Tampa, Florida may be known for its beaches, shorelines and restaurants, but this coastal region has become much more than a vacation spot. In 2023, Tampa’s labor force grew by 4.6 percent and was ranked by WalletHub as the second-best place to start a business. According to the Tampa Bay Times, CompTIA named the area one of the nation’s top 20 “tech towns,” alongside up-and-coming tech hubs like San Diego and Raleigh.

This recognition highlights Tampa’s growing reputation as a center for technological innovation, with 3D printing playing a pivotal role in this transformation. Several key industries based in Florida, medical and maritime, are at the forefront of utilizing 3D printing technology. Additionally, local educational institutions such as Florida College and the University of Tampa are incorporating 3D printing into their curricula, preparing students for future careers in this rapidly evolving field.

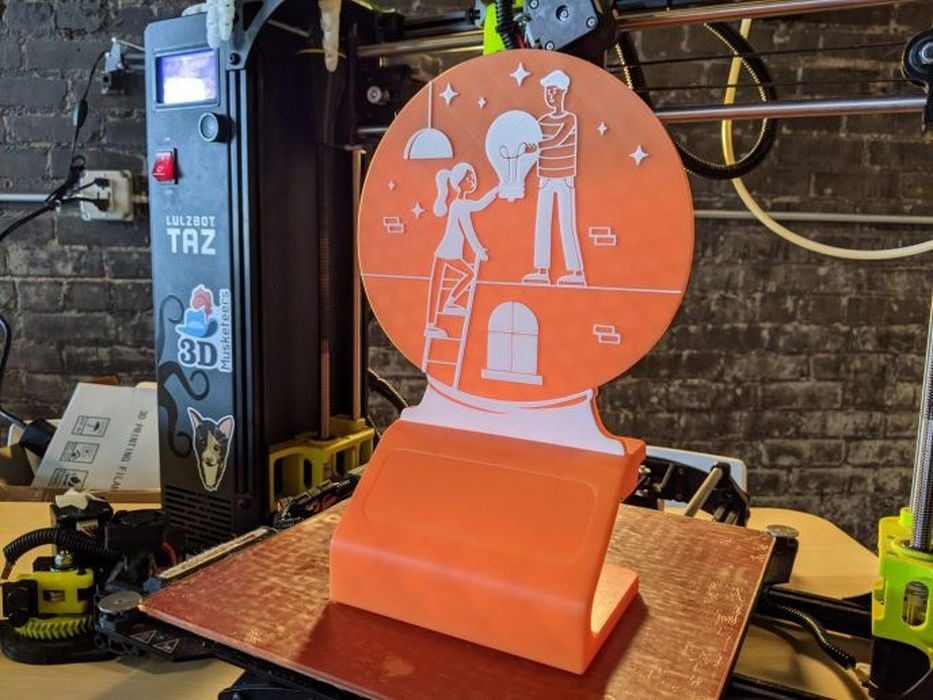

3D Musketeers With their values touted as “education, protect, and create,” Tampa-based 3D Musketeers takes on challenging 3D printing projects from clients ranging from the Smithsonian to CBS and Walt Disney, and provides exceptional 3D printing and scanning services. They specialize in bringing products to market. They also assist with forensic pathology 3D printing to invent help. To understand more about them check out their blog, or, if you are on the go, their podcast, Making Awesome.

The Transformative Role of 3D Printing in Tampa’s Medical and Maritime Industries

Tampa, Florida, has emerged as a pivotal hub for innovation, particularly in the realms of medical and maritime industries. Central to this wave of innovation is 3D printing, a technology that is revolutionizing both fields by offering unprecedented customization, efficiency, and cost-effectiveness.

3D Printing in Tampa’s Medical Industry

In the medical sector, 3D printing has enabled significant advancements in prosthetics, medical devices, and even bioprinting. Tampa’s healthcare institutions and startups are at the forefront of leveraging this technology to enhance patient care and medical research.

One notable example is the customization of prosthetics. Traditional prosthetic limbs can be prohibitively expensive and often require long waiting periods. However, companies in Tampa, such as LIM Innovations, utilize 3D printing to create affordable, custom-fit prosthetic limbs. These prosthetics are tailored to the unique anatomical requirements of each patient, significantly improving comfort and functionality. The rapid production capabilities of 3D printing also mean that patients can receive their prosthetics much faster than with conventional methods.

Additionally, 3D printing is being used to develop medical devices and surgical instruments. Tampa General Hospital, a leading healthcare provider in the region, has implemented 3D printing to create patient-specific surgical guides. These guides help surgeons plan and execute complex surgeries with higher precision, reducing the risk of complications and improving surgical outcomes.

Perhaps the most groundbreaking application of 3D printing in Tampa’s medical sector is in the field of bioprinting. Research institutions such as the University of South Florida’s Health Morsani College of Medicine are exploring the potential of 3D bioprinting to create organ and tissue models. These bioprinted structures are used for drug testing and disease modeling, paving the way for more personalized and effective treatments. While fully functional bioprinted organs are still in the research phase, the progress made in Tampa showcases the potential of 3D printing to eventually address organ transplant shortages.

3D Printing in Tampa’s Maritime Industry

The maritime industry in Tampa is also experiencing a transformation due to 3D printing. The Port of Tampa Bay, one of the largest ports in Florida, is leveraging this technology to enhance shipbuilding, maintenance, and logistics.

Shipbuilding has traditionally been a labor-intensive and time-consuming process. However, companies like Tampa Yacht Manufacturing are adopting 3D printing to create complex ship components with greater efficiency and precision. By using 3D printing, these companies can produce parts that are lighter, stronger, and more durable, leading to better overall performance of the vessels.

In addition to shipbuilding, 3D printing is revolutionizing maritime maintenance and repair. The ability to produce spare parts on-demand means that ships can minimize downtime by having critical components printed locally, rather than waiting for parts to be shipped from distant manufacturers. This capability is particularly beneficial for the cruise and cargo ships that frequent the Port of Tampa Bay, ensuring that operations remain smooth and uninterrupted.

Furthermore, 3D printing is being utilized to create custom tools and equipment for maritime operations. For instance, specialized fixtures and jigs that are used in the repair and assembly of ship components can be rapidly prototyped and produced using 3D printing. This not only speeds up the maintenance process but also allows for the continuous improvement of tools based on real-time feedback from maritime engineers.

3D Printing in Education: Florida College and University of Tampa

In addition to corporate advancements, educational institutions in Tampa are integrating 3D printing into their programs, preparing students for future careers in this innovative field.

Florida College

Florida College has made significant strides in incorporating 3D printing into its curriculum. The college’s engineering and technology departments have introduced courses that focus on additive manufacturing techniques. Students have access to state-of-the-art 3D printing labs where they can design and create prototypes for their projects. A recent student project involved the creation of custom prosthetic limbs. By utilizing 3D printing, students were able to produce affordable and functional prosthetics, showcasing the practical and humanitarian applications of this technology.

University of Tampa

The University of Tampa (UT) is also at the forefront of 3D printing education. The university’s Department of Art and Design has embraced 3D printing as a tool for artistic expression and innovation. Students in the graphic design program use 3D printers to create intricate models and sculptures, pushing the boundaries of traditional art forms. Additionally, UT’s business school has introduced courses on 3D printing and its implications for entrepreneurship. These courses provide students with a comprehensive understanding of how additive manufacturing can be leveraged to create new business opportunities.

A notable initiative at UT is the collaborative project between the engineering and biology departments. This project involves the development of 3D-printed models of biological structures, such as organs and tissues, for educational and research purposes. By creating accurate and detailed models, students and researchers can gain a deeper understanding of complex biological systems, enhancing both their learning and investigative capabilities.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Tampa, Florida, is rapidly emerging as a hub for technological innovation, with 3D printing playing a central role in this transformation. Industries in the Tampa area, like healthcare and maritime, are leveraging additive manufacturing to enhance their prototyping and production processes, driving efficiencies and innovations in their respective industries. Meanwhile, educational institutions such as Florida College and the University of Tampa are equipping students with the skills and knowledge needed to thrive in the burgeoning field of 3D printing.

As Tampa continues to develop its tech ecosystem, the integration of 3D printing across various sectors highlights the city’s commitment to embracing cutting-edge technologies. This not only positions Tampa as a leader in the tech industry but also ensures that the region remains at the forefront of innovation and economic growth for years to come.