We’re finally seeing some details about the upcoming Bambu Lab 3D printer. What do we know so far?

As long ago as October, Bambu Lab hinted that they were about to announce a new 3D printer before the end of the year. However, the company then announced a significant delay for unexplained reasons.

Coincidentally, that was also the time when Stratasys launched a patent infringement lawsuit against Bambu Lab. I believe there could be a connection there, and this will be discussed further in a future post.

But back to the new “H2D” 3D printer that has been rumoured for a while.

Two things have happened. First, Bambu Lab issued a mysterious announcement with a dark image of what seems to be a toolhead, with the date of March 25 as the release date.

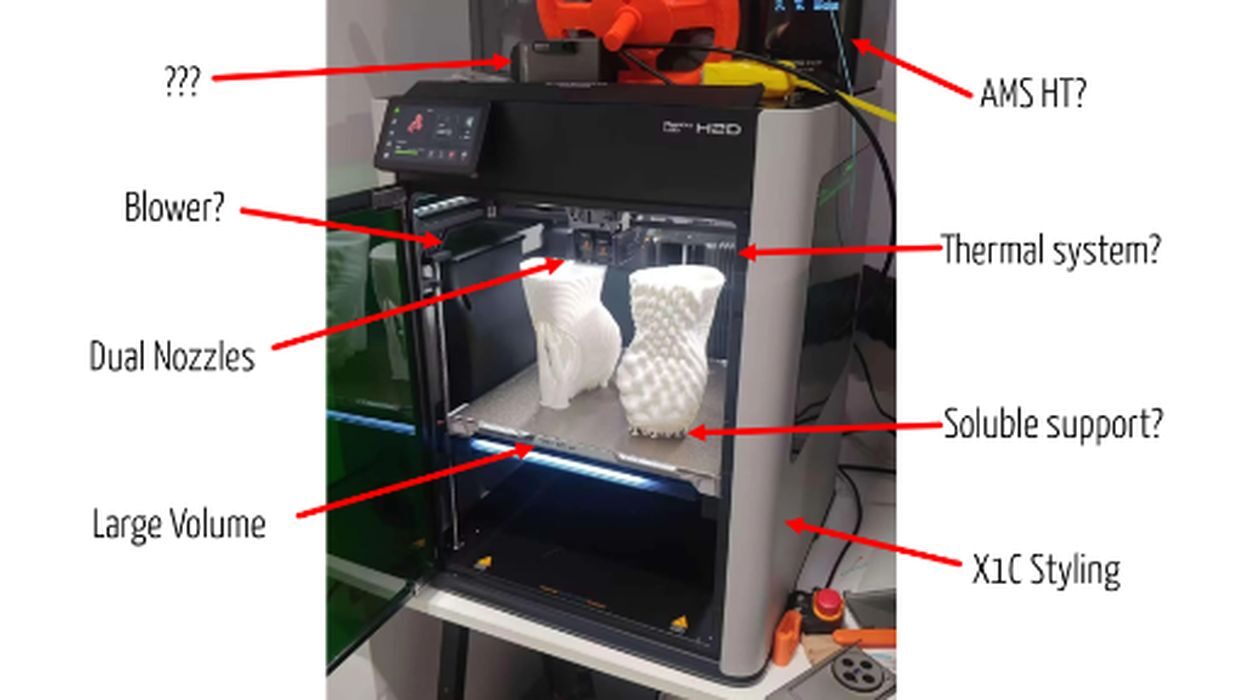

Secondly, a Reddit post appears to have a full image of the rumoured H2D machine.

H2D Announcement

Let’s take this all apart, beginning with the official announcement. Bambu Lab’s official wrote:

”Bambu Lab H2D

The wait ends on March 25!

Bambu Lab H2D is coming to make you rethink personal manufacturing.”

The date seems reasonable, but what about the use of the words, “personal manufacturing”? That’s a phrase I have never heard from a desktop 3D printer manufacturer.

I presume Bambu Lab wishes to differentiate the H2D from other products, and they intend on doing so by positioning it for “personal manufacturing”.

But what does that mean? “Manufacturing” typically means the repeated production of a part. It could also mean that a single part is manufactured, but that’s the same as any 3D printer, so no differentiation there.

Could this tagline mean that the H2D might have some means of continuous production? After looking at the supposed image of the H2D below, it seems that this is not the case.

“Personal manufacturing” might instead mean that the device is capable of handling a wide range of proper engineering materials in an easy manner.

H2D Cryptic Image

Let’s look at the image of the toolhead posted by Bambu Lab. Here’s the image with the levels stretched a bit for more visibility:

We can see that there are two extruders present in the single toolhead. This is a mechanism used by many 3D printers, and typically the toolhead would slide to the sides to “clunk” the correct extruder into position. It’s a way to have two materials ready to go at all times without having to wait for AMS feeds and delays.

We can also see two filament cutter arms, one on each side of the toolhead. This suggests that the H2D will be AMS compatible, and allow perhaps four filaments per extruder, so eight in total?

I don’t see anything else of note in the image.

H2D Analysis

Adding this up suggests they have devised a new extrusion system that offers one significant benefit: reduced poop.

If you were to print with two materials only, then there would be no poop at all. The toolhead would simply clunk over to each material as required.

If you used more than two materials, then the AMS approach would apply as usual, and some poop would be required when the filament is cut. Nevertheless, the H2D could substantially reduce the amount of poop waste produced on many jobs.

Alleged H2D Image

What about the image of the H2D? Let’s look at that and see what appears.

Aside from the obvious labeling and styling, which are definitely Bambu Lab, we can see a bit more of the toolhead.

The toolhead in the printer image also has two hot ends. Note that one is higher than the other. This is the normal way toolheads of this type work: the inactive hot end rises to get out of the way.

This switch is done mechanically by bumping the toolhead against the sides. There should be a spot on the sides where this happens, and it looks like they could be using the top of the left front Z-axis for this purpose.

There’s one very curious omission: Bambu Lab’s dark image clearly has cutters on the sides of the toolhead, yet there doesn’t seem to be any on this printer’s toolhead.

Could this be the “non-AMS” version of the toolhead? There’s also no cover on the toolhead, which is interesting. Perhaps this is an image of an early prototype model, and things changed afterwards. This could make sense, as Bambu Lab would first have to get the machine working as a standalone device, and then later integrate the AMS functionality.

The build plate is labeled “350 x 320 x 325 mm”, which is obviously far bigger than the current build volume on Bambu Lab machines. This will be quite welcome by the community, which has been screaming for larger build volumes for quite some time.

The build plate itself appears to be the same tech as today’s Bambu Lab machines, just bigger. There is no evidence of any continuous 3D printing capability.

I also notice some interesting venting in this image. At the rear, there is a grill-like surface that might suggest an active heating system. This would differ from most enclosed heating systems, which simply keep stray heat from the print bed and hot end from escaping.

It could be that the H2D includes an active heating system to ensure precise build temperatures. That would be very important for printing engineering materials, and that aligns with the “personal manufacturing” tagline.

There’s also a strange slot hole on the left side of the chamber with a curved surface. At the top of this apparatus is what looks like an air vent. This could also be part of a complex thermal control system. I’m not sure what the hole is for, however. Could it be a new poop chute?

The prints in the image don’t seem particularly special, but they both make copious use of support material. I would guess that soluble support would be a very typical use of this dual-nozzle machine, with support in one extruder and model material in the other.

I’m wondering what material is being printed. It could be simply white PLA. But it might also be something more exotic, like nylon. If so, that would also align with the personal manufacturing tagline.

At the top of the image, there is more interesting stuff to see.

In the top right corner, we have a device on top of the H2D with a digital display. We see “27%” and “34C”, and a countdown timer. This is obviously a filament drying system.

However, underneath it says “…MS HT”. I suspect this is in fact the “AMS HT”, or “high temperature” version of the AMS. Currently, the AMS simply stores spools; it does not condition them.

The new AMS HT seems to have an integrated filament drying system, which, again, aligns with the personal manufacturing with engineering materials concept.

I have no idea what the small grey box on the left top is for. It seems to have Bambu Lab-like labeling on it, but it is unreadable. The styling suggests it could be an accessory for the H2D. It has what looks like a 2×6 connector; perhaps this is for connecting AMS units?

H2D Summary

Putting all this together, we have the H2D looking something like this:

- Build volume: 350 x 320 x 325 mm

- Large magnetically attached PEI-coated print plate

- Precisely controlled thermals in the build chamber

- Very likely higher extrusion, plate, and chamber temperatures

- AMS-enabled dual nozzle toolhead

- Faster multimaterial printing

- Dramatically reduced poop

- Likely the ability to easily print a wide range of engineering materials

- Accompanied by AMS HT with integrated filament drying

This looks to be a very interesting device, and I’d like to learn more. But we’ll have to wait until the 25th for that.