There are a number of reports of issues with recent filament spools from Bambu Lab. What’s going on?

The problem seems to be regarding tape that holds the end of the filament to the spool’s hub. When the spool is exhausted, the last segment of filament is pulled off the spool and heads into the AMS (or AMS Lite). There, the end of the filament will be detected and the operator asked to replenish the material.

That’s how it’s supposed to go, but in some cases it isn’t.

A problem can occur if the tape that holds the end of the filament sticks to the filament instead of the spool hub. It’s possible for the end of the filament to have this piece of tape stuck to it, and that travels up into the AMS (or AMS Lite) with the filament.

When it arrives in the AMS unit, the tape can cause jams and other problems. Sometimes this requires quite a bit of repair as some disassembly may be required to extricate the wayward tape. At the very least, the job is jeopardized.

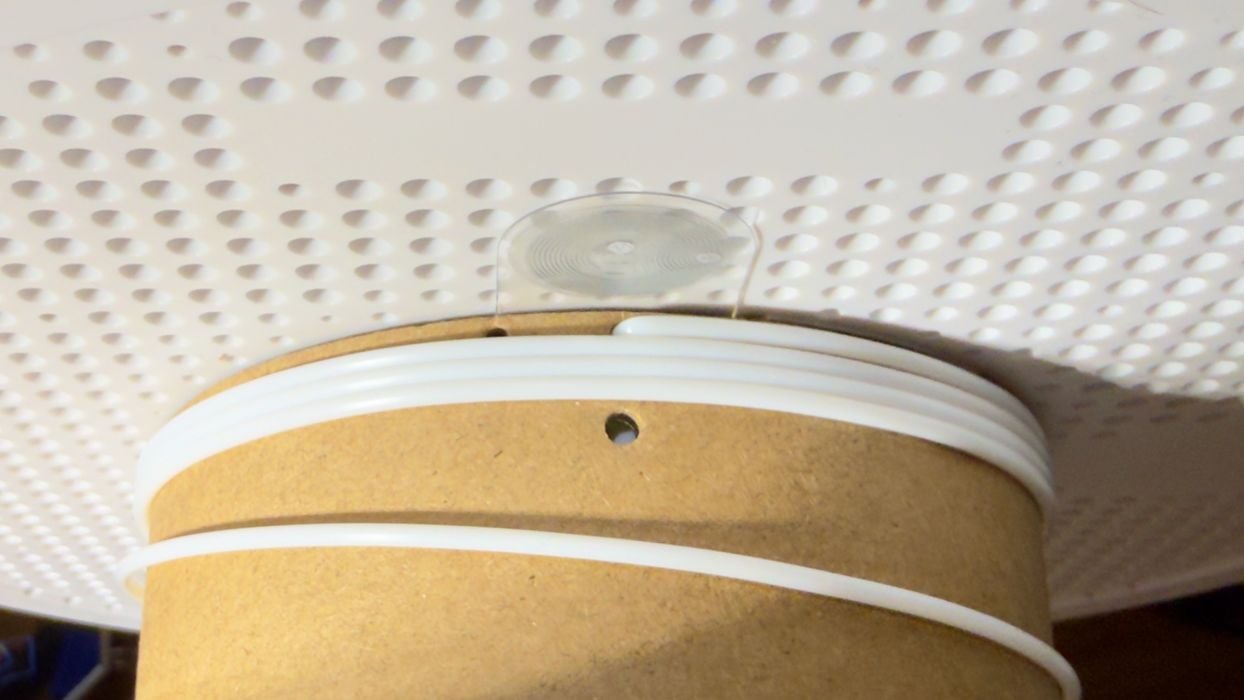

This seems to be a relatively recent problem. Earlier spools from Bambu Lab didn’t use tape, and instead simply had the end of the filament poked into a hole in the spool hub, as shown above.

However, a recent change in spool production introduced the tape approach, and some have had problems ever since using these new spools.

There are considerable discussions online about this issue, and Bambu Lab is surely is aware of the issue. I reached out to my contacts at Bambu Lab to see if they were aware of the tape issue and what could be done about it.

I received this official response:

“Yes, we are aware of the challenges some users have experienced with the tape on our filament spools. This issue emerged from our efforts to improve the AMS (Automatic Material System) experience – specifically, to prevent filament end entanglement that was causing AMS removal difficulties. While the tape solution addressed the original problem, we acknowledge that it has created new concerns for some users.

We take product quality very seriously, and our R&D team has been actively working on this issue. We have already implemented enhanced quality control measures in our production process to ensure proper tape application. Our R&D team continues to work on further improvements to enhance the overall user experience.

For complete transparency, we have published a detailed report about this issue on our community forum (https://forum.bambulab.com/t/tape-at-the-end-of-spool/13128/13), where we discuss the problem, its origins, and our ongoing efforts to resolve it.

Users experiencing issues with the tape are encouraged to open a support ticket through our customer service portal so we can assist them directly.

We’re committed to continuous improvement and appreciate our community’s feedback in helping us identify and address issues like this.”

So it seems they are definitely aware of the issue, and have been working on a fix. It’s not as simple as just “not using tape”, as many would suggest. Bambu Lab introduced the tape as a way to solve a different issue, so avoiding tape brings back that issue.

Bambu Lab has a good track record of fixing issues, although it can take them time to develop and deploy the solution. They did so quite well with the A1 heat bed issue, and I’m confident in them solving this one, too.

However, the tape issue may be a bit trickier to solve because of the lifetime of spools. Often operators buy a large batch of spools at once, and then burn through them over a longer period of time. Sometimes it can take years for all of a purchase to be used up, depending on the needs of the operator. I have some spools here that I haven’t opened after 2+ years.

For those with inventories of filament, the tape issue could pop up unexpectedly in the future when an older spool is pulled off the shelf. When Bambu Lab does fix the issue, I am hoping they provide some kind of marking system on the spool so that we’d know whether a random spool is or isn’t susceptible to the tape problem.

Via Bambu Lab