Charles R. Goulding and Preeti Sulibhavi drill into Baker Hughes’ transformative use of 3D printing, highlighting its strategic partnerships and impact on the energy sector.

Baker Hughes provides high quality oilfield servicing products. Baker Hughes has invested heavily in 3D printing.

As of Fall 2024, Baker Hughes (BKR) had an enterprise value of US$36.95 billion, reflecting the total value of the company based on its market capitalization and debt adjustments. The company reported US$27.3 billion in revenue over the past twelve months, representing an 11.08% year-over-year growth. Additionally, Baker Hughes has a workforce of approximately 58,000 employees, with notable growth of 5.45% from the prior year.

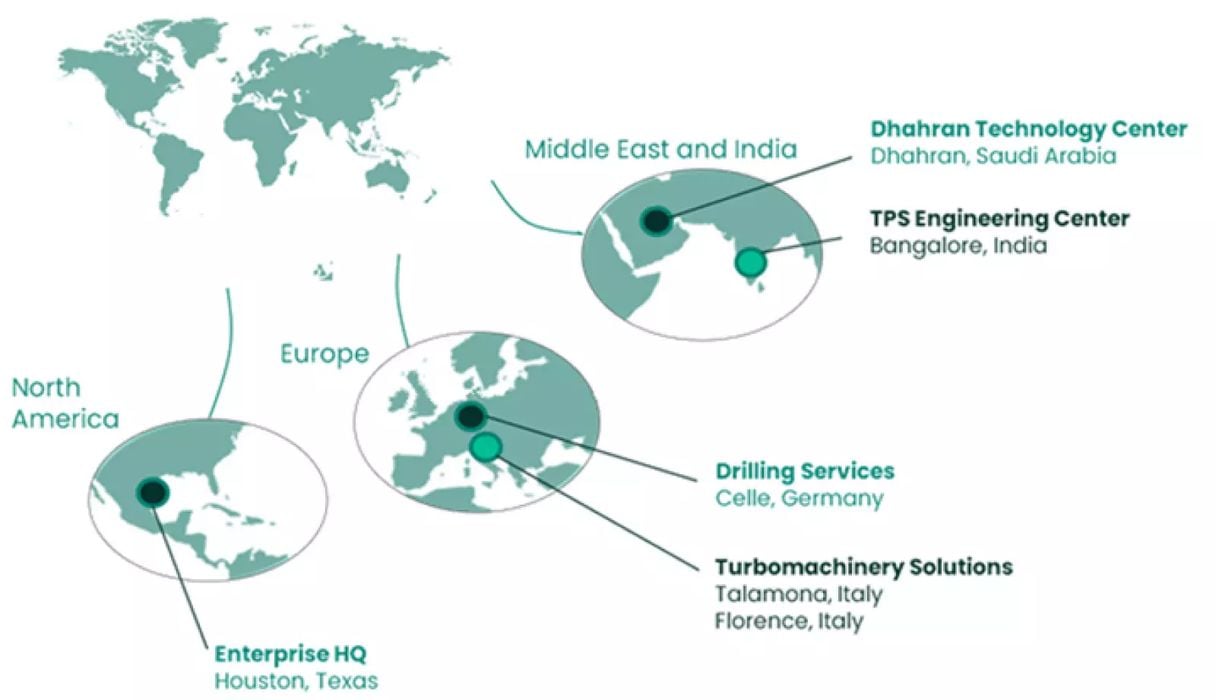

Baker Hughes integrates 3D printing into its global supply chain to streamline processes, reduce inventory, and lower costs related to inventory taxes and delivery times. This is part of a broader strategy to enhance operational efficiency and customer responsiveness while supporting the energy transition.

Below are three other examples of the company’s engagement with additive manufacturing and related joint ventures:

Collaboration with Oqton

Baker Hughes partnered with Oqton to create a comprehensive software suite aimed at industrial-scale additive manufacturing. This collaboration combines Baker Hughes’ industry knowledge with Oqton’s Manufacturing OS (MOS) software platform, enabling an integrated, digital manufacturing workflow. The software supports design, production, and quality control for sectors like energy, aerospace, and healthcare, enhancing efficiency and traceability

Joint Venture with Saudi Industrial Investments (Dussur)

Baker Hughes formed a joint venture with Saudi Dussur to set up a Center for Innovation and Additive Manufacturing in Saudi Arabia. This facility, which focuses on on-demand printing and application engineering, serves energy, defense, and healthcare markets. The partnership aims to localize advanced manufacturing capabilities in the region, supporting supply chain security and job creation.

Research Partnership with Saudi Aramco

Baker Hughes also collaborates with Saudi Aramco through research initiatives focusing on advanced additive manufacturing and materials science. This research partnership explores new manufacturing technologies that support operational efficiency and sustainability in the energy sector, contributing to both companies’ goals of advancing clean energy technology

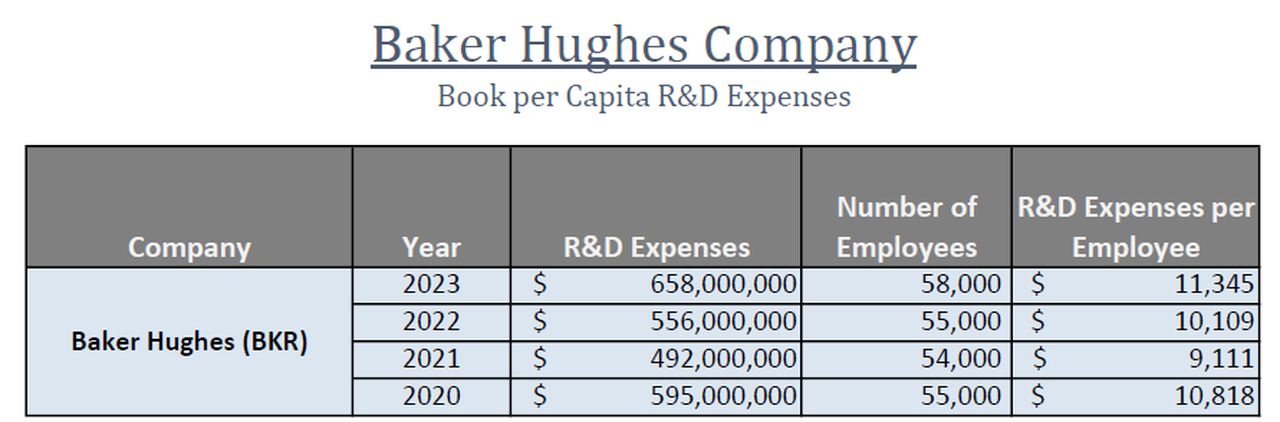

These ventures highlight Baker Hughes’ commitment to advancing additive manufacturing across its operations and supporting innovation in industrial and energy applications. The table below presents the amount of increasing research and development expense incurred by Baker Hughes over the past few years.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

If an industry giant like Baker Hughes is integrating 3D printing technology into its worldwide supply chain operations, other companies are likely to follow. This means that 3D printing will become more relevant not only to the oil and gas industry but to other verticals as well.