There are considerable implications from this week’s announcement of a 3D Scan to CAD service from Backflip.

The AI startup announced an upcoming service that uses an AI trained on 50M+ CAD models to automatically generate true CAD models directly from 3D scan data. Read more about it here.

This technology is beyond amazing, but I expect a number of consequences will occur in the 3D print community.

First, the target market for the technology will be met. Backflip CEO Greg Mark told us the original intention of the product was to enable factory workers untrained in CAD to produce parts immediately on production lines. While the technology was always there to print the parts, the designs were not. With 3D Scan to CAD, they will be.

This will certainly reduce downtime in every production line that uses this approach, because there will be fewer delays in waiting for line repairs when something breaks.

But there are a number of other implications.

CAD Training

One is training. If you watched the demonstration video from Backflip, you’d see that the CAD features generated by the system are applied almost instantly. It’s like watching a highly skilled CAD user operate at warp speed.

Mark told us (and showed us) that if you can slow down the CAD execution. This makes it possible to see the method of drawing the object in a step-by-step fashion. That might be ideal for teaching new CAD users on best practices, since the AI is literally trained on best practices for CAD.

Reverse Engineering

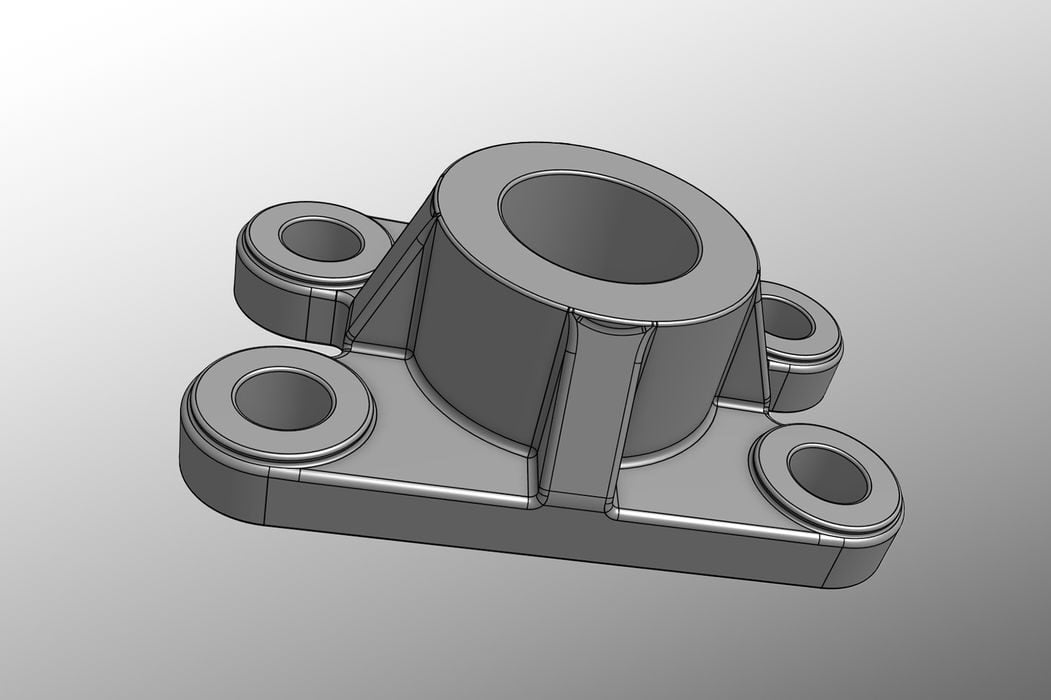

Reverse engineering has long been a thing in manufacturing. Parts are scanned and then a laborious process of redrawing the part in CAD. It’s much like tracing a 2D image on paper, except that it’s done in 3D. Up to now, that’s been the only approach for transforming a rough 3D scan into a usable CAD part design.

There are a number of tools on the market that specialize in reverse engineering. I have a suspicion that all of them could face challenges ahead, as Backflip’s new service will only get better over time.

Scanner Sales

The ease with which one can create a proper CAD model using the service implies more people will be able to do reverse engineering. However, you still need a 3D scanner to capture the scans. My suspicion is that 3D scanner sales could leap upwards.

This would include not only typical handheld 3D scanners, but will also focus on specialized 3D scanners that could be easily operated in Mark’s factory scenario. Imagine a setup where factory workers can just drop a part into a box where a good-quality scan is obtained at the touch of a button. That would be an outstanding complementary hardware item for this service.

CAD Sales

The ease of use will likely also boost sales of CAD software. While Backflip has initially integrated their service with SOLIDWORKS, I have a suspicion they will also provide integrations with a number of other popular CAD systems in the future.

Text to 3D

There’s another immense implication, if you think about what’s been happening in the AI 3D world lately. Prior to Backflip’s new service, there have been multiple “text to 3D” services. These accept a text prompt and generate a 3D model.

Typically, these services generate very rough approximations of what was asked, of a quality we’d call “plastic dragons”.

Now think about this: imagine if a Text to 3D service was trained on mechanical parts instead of gaming assets. That would generate rough mechanical part 3D meshes.

But isn’t that just what a 3D scan is? The same things that go into 3D Scan to CAD?

Now imagine this: you start with a text prompt asking for a specific mechanical part design. You refine it by adding follow-up instructions. When it’s done to your liking, you then transfer that into 3D Scan to CAD — and you have a CAD model created out of thin air without any 3D scan taking place.

That could create new parts, not just reverse engineering of existing parts. In other words, we could have an explosion of innovative designs driven by AI services built on top of Backflip.

In fact, when I spoke with Mark this week, he said that they could eventually go from idea to shape to CAD to print. However, Backflip’s intent is not to replace CAD, but instead to make it easier to get into.

AI Stacking

After my discussion with Mark, I thought about this further and realized there’s another stage that could occur. In the AI world today, there’s often a pattern used to supercharge the results. Text AI systems were instructed to “show their work”, or “provide the steps required to do it”, etc. These are effectively a higher level of design.

This has resulted in stages where first an “architecture” is generated by the AI, and then later the components of that architecture are themselves generated in detail. The resulting collection of components is then assembled into a complex system.

Backflip’s 3D Scan to CAD service could make this achievable in 3D printing. An ultimate future system might be able to accept a complex text prompt and then generate not a part — but a system of parts that make up a complex machine.

At that point, I don’t know what will happen.

But it will be interesting.