AM-Flow launched a new component to their growing post-processing toolkit.

For those unfamiliar with AM-Flow, they develop a series of components that can be assembled to provide automation for completed 3D prints. There are some 3D printing systems that automatically process up to removing parts from the machine, but what happens then? How do you handle potentially thousands of parts coming off a print farm every hour?

In the past, that was largely done manually, with staff picking through piles of hopefully labelled parts. That method was error-prone and expensive. AM-Flow’s systems include a variety of automated workstations and conveyor systems to take parts between stations. In fact, it’s quite possible to set up an automation line where you literally dump a pile of parts on a table, and AM-Flow’s system does all the rest for you automatically.

The new development we saw at Formnext was the addition of the AM-Quality system. This is a quality control station, but with a difference: it scans incoming parts in 360 degrees. AM-Flow says this is the world’s first automated in-line solution that can do this, and that’s likely true.

The concept is straightforward: a part is conveyed into the chamber, where it is 3D scanned. The scan is then compared to the desired 3D model, and an analysis is prepared. If the part doesn’t meet tolerances, it can be sent off to the discard pile, if that’s the intent.

The system is able to fully scan the incoming part in only seconds, and it then performs a boolean subtraction to identify any dimensional or geometric issues.

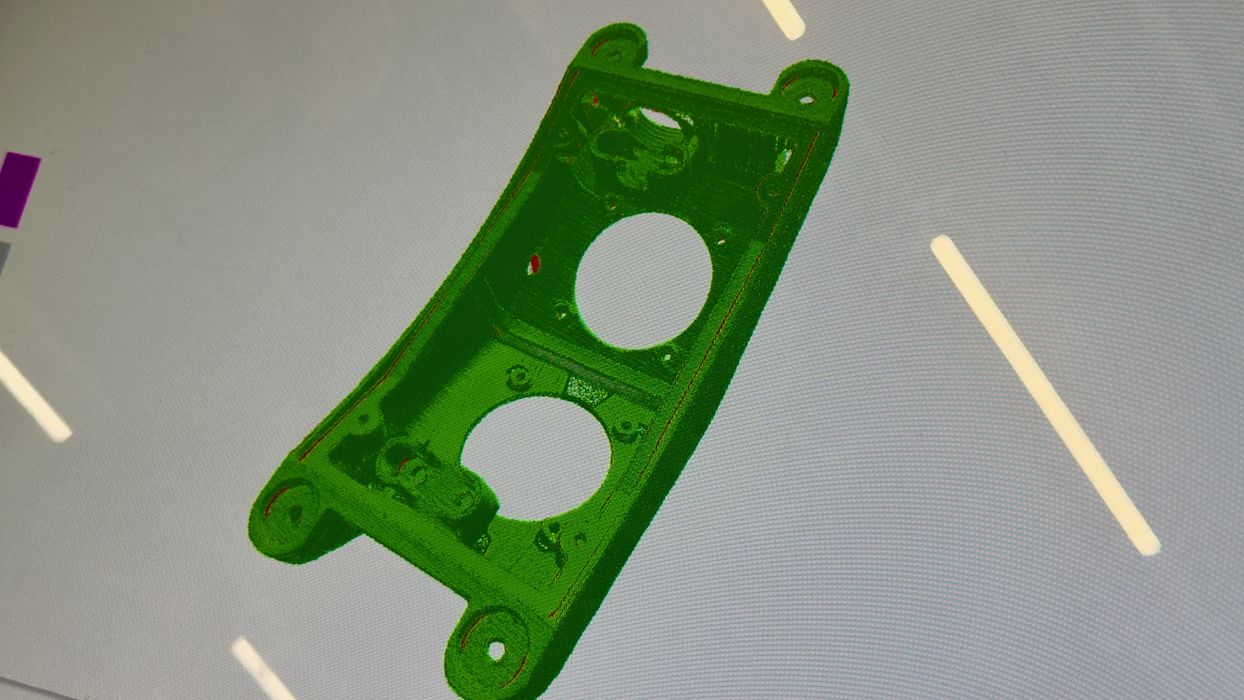

Here we see an analysis of a part, and there’s a red spot indicating that something is wrong. Below you can see the actual part that was scanned, and sure enough, there was a hole in the part at that location.

AM-Flow explained that the system is quite different from their sorting station, where only one side of the part is scanned. That scan’s goal is to identify the part, not quality-check its entire surface.

The AM-Quality station involves stitching no less than eight different scans that take place inside the machine. Above you can see a rotating contraption that takes parts through the scanning process.

This is quite a milestone for AM-Flow, as it now enables customers to mostly complete a production line — including quality control. Once set up, operators would need only dump parts into the system at one end, and pick up separate bins of good and bad parts at the end.

Via AM-Flow